Internal expansion unfolding mechanism and unfolding method for cylindrical part carbon fiber winding preparation process

A technology of preparation process and unfolding mechanism, which is applied in household components, applications, household appliances, etc., can solve problems such as complex design structure, troublesome use methods, and affecting work efficiency, and achieve the effect of simple structure, high efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

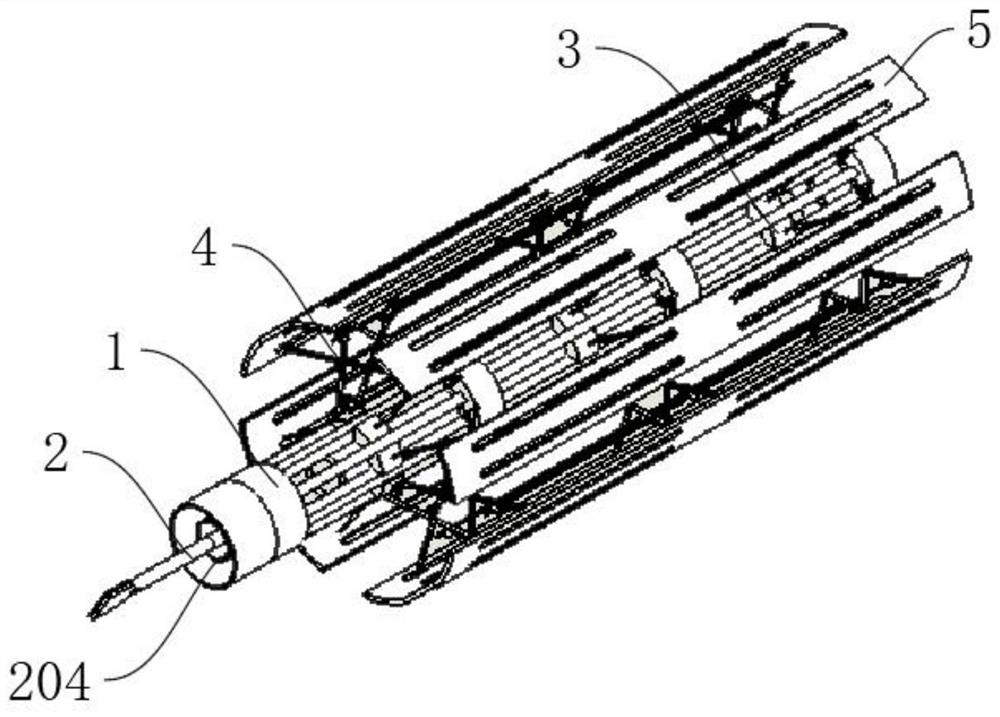

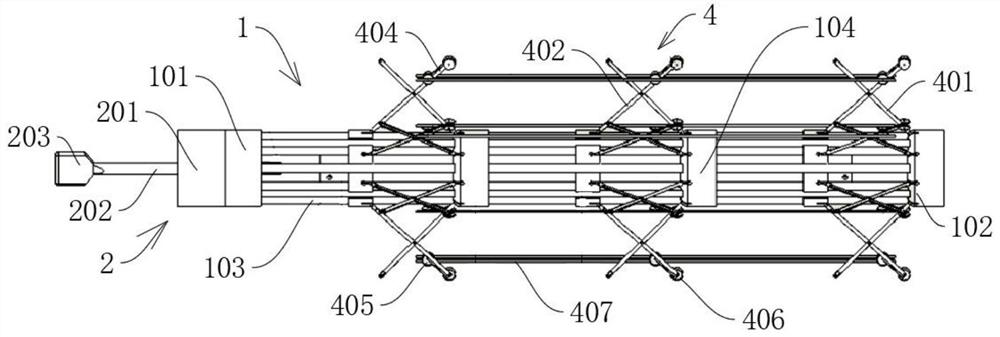

[0037] see Figure 1-6 , the internal expansion and deployment mechanism used for the filament winding preparation process of cylindrical parts, including a mandrel body 1, the top of the mandrel body 1 is connected with a driving mechanism 2, and the inside of the mandrel body 1 is provided with an inner core mechanism 3, the inner core The mechanism 3 is matched with the drive mechanism 2. The mandrel body 1 and the inner core mechanism 3 are connected with a support mechanism 4. The support mechanism 4 includes a main support group and an auxiliary support group. Both the main support group and the auxiliary support group are connected to the mandrel body. 1 is connected with the inner core mechanism 3, and the support mechanism 4 is also connected with a support shell 5.

[0038] The two ends of the mandrel body 1 are set as a top sleeve 101 and a bottom sleeve 102, and an outer core wedge rod 103 is fixedly connected between the top sleeve 101 and the bottom sleeve 102, a...

Embodiment 2

[0045] see Figure 1-6 The difference in the basis of Embodiment 1 is that both the main support group and the secondary support group include multiple sets of first support rods 401 and second support rods 402, and the middle of the first support rods 401 and second support rods 402 The first support rod 401 and the second support rod 402 are fixedly connected with a spherical rod head 403 on the side close to the mandrel body 1 through the connecting hinge, and the spherical rod head 403 at the end of the first support rod 401 of the main support group is connected to the bottom by rotation. In the support rod installation groove 105 on the sleeve 102, the spherical rod head 403 at the end of the first support rod 401 of the auxiliary support group is rotatably connected in the support rod installation groove 105 on the outer core holder 104, the main support group and the auxiliary support group The end of the first support rod 401 away from the spherical rod head 403 is ro...

Embodiment 3

[0049] Based on Example 1-2 but different in that,

[0050] The method for deploying the internal expansion and deployment mechanism used in the filament winding preparation process of cylindrical pipe fittings includes the following steps:

[0051] S1. Before use, put the disposable rubber tube on the supporting shell 5, and the disposable rubber tube expands with the supporting shell 5;

[0052] S2. Cover the inner wall of the hose to be expanded with soft foam to reduce the interaction between the support shell 5 and the inner wall of the hose;

[0053] S3. Push the device body covered with a disposable rubber sleeve into the hose, adjust the length of the threaded rod 202 relative to the connecting seat 201 through the elastic knob 203, and then adjust the position of the inner core rod 301, so that the support mechanism 4 drives The support shell 5 expands outward;

[0054] S4. After expanding to a suitable degree, stop rotating the elastic knob 203, and realize the tig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com