Method for treating high-arsenic waste acid by using modified coal cinder adsorbent

An adsorbent, arsenic polluted acid technology, applied in adsorption water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. The effect of processing meaning, reducing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

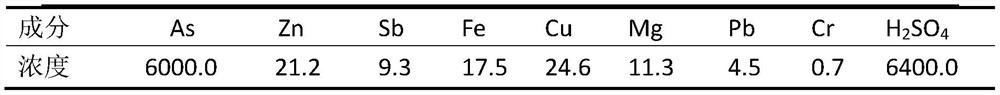

[0026] A method for treating high-arsenic polluted acid with a modified coal slag adsorbent, the specific steps are as follows:

[0027] (1) H 2 o 2 The solution was added to high-arsenic polluted acid, and reacted for 4 hours at a temperature of 80°C and a stirring rate of 180r / min to obtain solution A; where H 2 o 2 The concentration of the solution is 30%, H 2 o 2 The volume ratio of the solution to the high-arsenic polluted acid is 1:4-6;

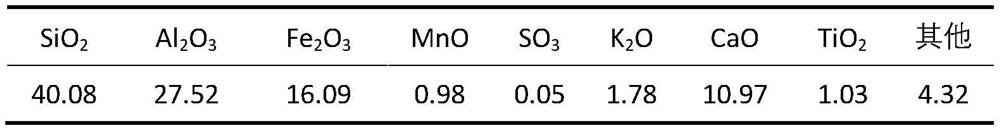

[0028] (2) Add 50g honeycomb coal slag powder and 10g NaOH to 500ml deionized water to obtain solution B, stir and react at 25°C for 2-3 hours, separate solid and liquid to obtain modified coal slag and filtrate, and dry the modified coal slag for 12 hours deal with.

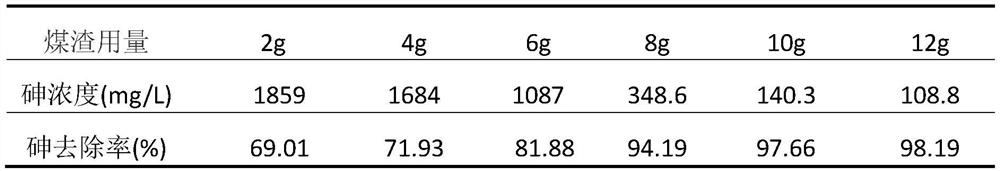

[0029] (3) Add the prepared modified cinder powder into 50ml of solution A in step (1), shake in a constant temperature oscillator at a temperature of 25°C at a shaking speed of 180r / min for 24h, and separate solid and liquid to obtain arsenic-containing solid The ...

Embodiment 2

[0034] A method for treating high-arsenic polluted acid with a modified coal slag adsorbent, the specific steps are as follows:

[0035] (1) H 2 o 2 The solution was added to the high-arsenic polluted acid, and reacted for 4.5 hours at a temperature of 81°C and a stirring rate of 180r / min to obtain solution A; the concentration of the hydrogen peroxide solution was 30%, and the hydrogen peroxide solution and the high-arsenic polluted acid The volume ratio is 1:5;

[0036] (2) Add 50g honeycomb coal slag powder and 10g NaOH to 500ml deionized water to obtain solution B, stir and react at 25°C for 2-3 hours, separate solid and liquid to obtain modified coal slag and filtrate, and dry the modified coal slag for 12 hours deal with.

[0037] (3) Add 8g of the prepared modified cinder powder to 50ml of solution A in step (1), and shake and react in a constant temperature oscillator at a temperature of 25°C at a shaking speed of 180r / min, and separate solid and liquid to obtain ar...

Embodiment 3

[0042] A method for treating high-arsenic polluted acid with a modified coal slag adsorbent, the specific steps are as follows:

[0043] (1) H 2 o 2The solution was added to high-arsenic polluted acid, and reacted for 5 hours at a temperature of 82°C and a stirring rate of 180r / min to obtain solution A; where H 2 o 2 The concentration of the solution is 30%, H 2 o 2 The volume ratio of solution to high arsenic polluted acid is 1:6;

[0044] (2) Add 50g honeycomb coal slag powder and 10g NaOH to 500ml deionized water to obtain solution B, stir and react at 25°C for 2-3 hours, separate solid and liquid to obtain modified coal slag and filtrate, and dry the modified coal slag for 12 hours deal with.

[0045] (3) Add 8g of modified coal slag powder into 50mL solution A of step (1), and shake at a speed of 180r / min in a constant temperature oscillator with a temperature of 25°C, 40°C, 60°C, 80°C, and 90°C Shaking reaction for 24 hours, solid-liquid separation to obtain arsen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com