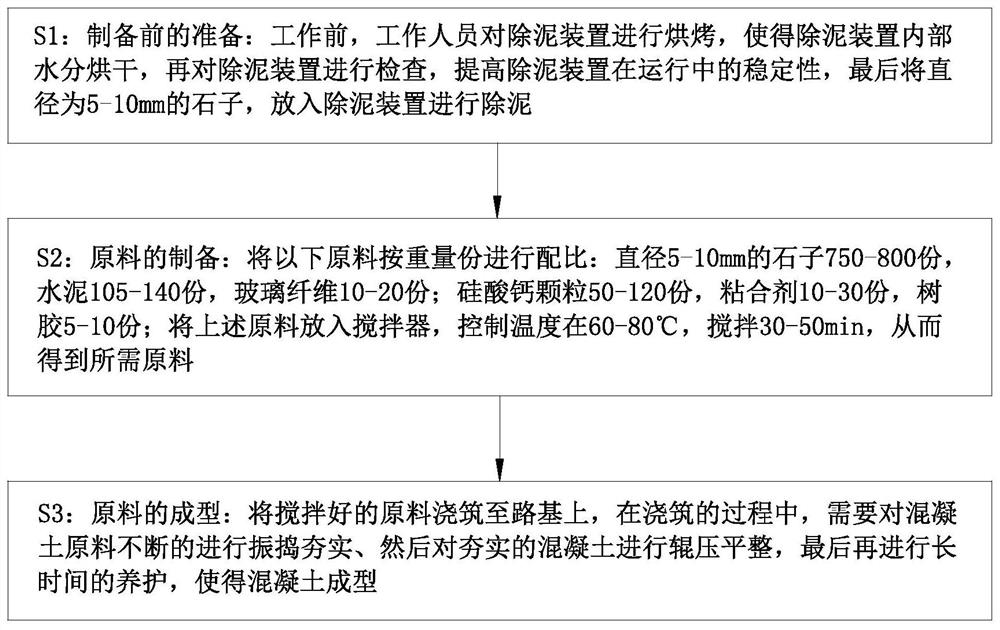

A kind of preparation method of high-strength permeable concrete

A technology for permeable concrete and concrete, which is applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of reducing soil cleaning effect, reducing concrete strength, concrete cracking and sanding, etc., to speed up the drop rate , The rubbing effect is strengthened, and the effect of increasing the rubbing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

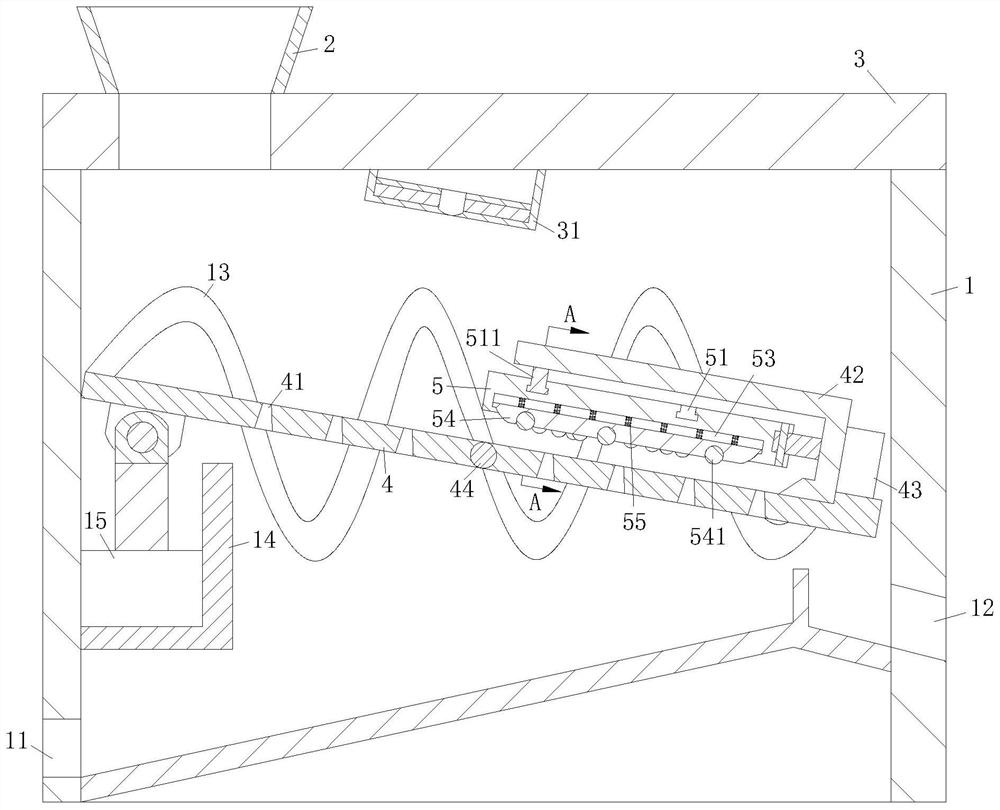

[0040] As an embodiment of the present invention, the cross-sectional shape of the No. 1 groove 51 is annular, and the outer side wall of the No. 1 groove 51 is provided with a No. 2 groove 52; the No. 2 groove 52 is provided with an arc. One end of the arc-shaped plate 521 is hinged on the side wall of the second groove 52, and the other end is connected with an arc-shaped block 523 through the torsion spring 522. The bottom of the groove 52 is fixedly connected by the No. 1 spring 524; during operation, the reciprocating motor 43 drives the push plate 5 to reciprocate, so that the sliding rod 511 slides along the No. 1 groove 51, and when the sliding rod 511 slides to the second position When the No. 2 groove 52 is in the position, the sliding rod 511 squeezes the arc-shaped plate 521, so that the arc-shaped plate 521 rotates along the side wall of the No. 2 groove 52 to the groove bottom direction of the No. 2 groove 52. While rotating, the end of the arc plate 521 away fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com