A gh3230 nickel-based superalloy material and its method and application for eliminating microcracks formed by laser selective melting

A technology of GH3230 and nickel-based superalloy, which is applied in the direction of additive processing and additive manufacturing, etc., to achieve the effect of strong practicability, simple doping method, and improved bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, a method for eliminating microcracks in laser selective melting forming GH3230 nickel-based superalloy is provided, including the following steps:

[0046] The specific preparation method is as follows:

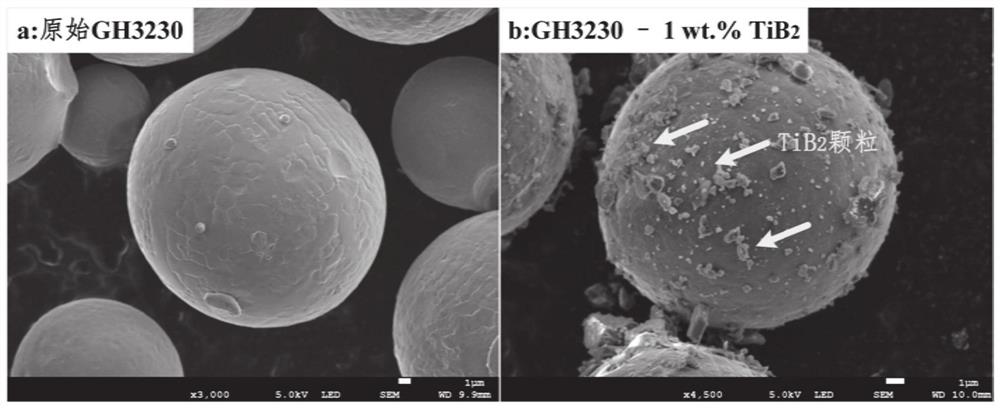

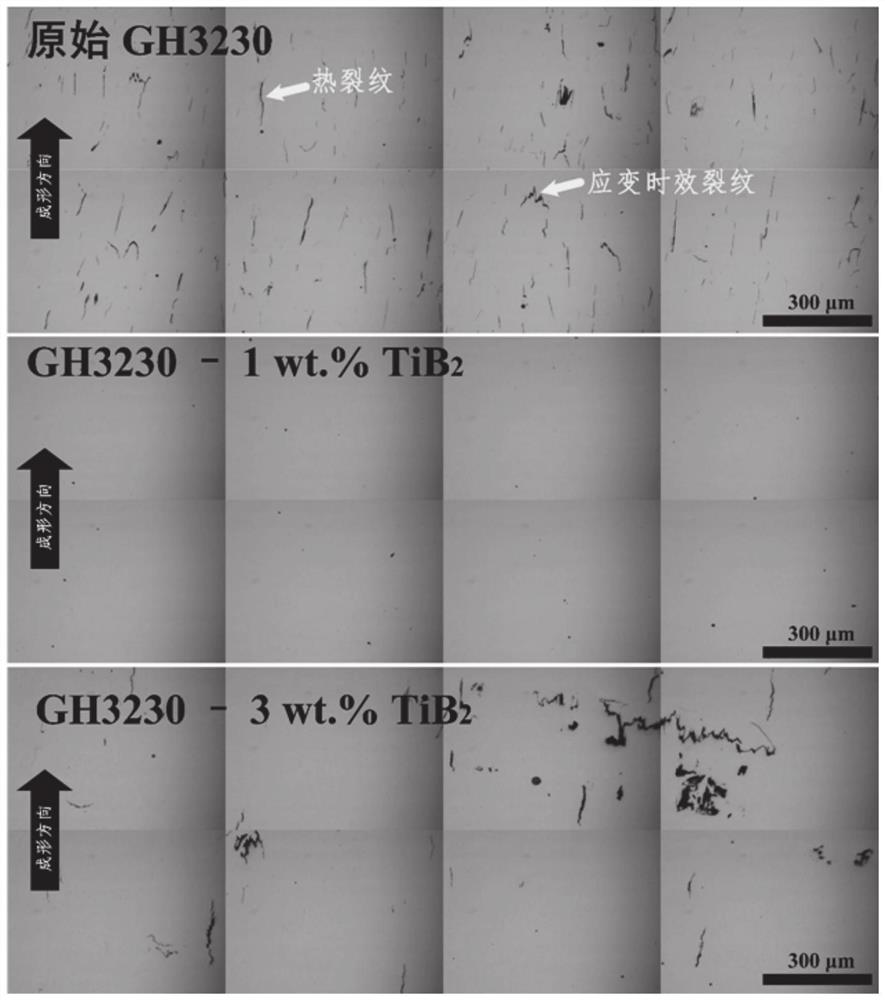

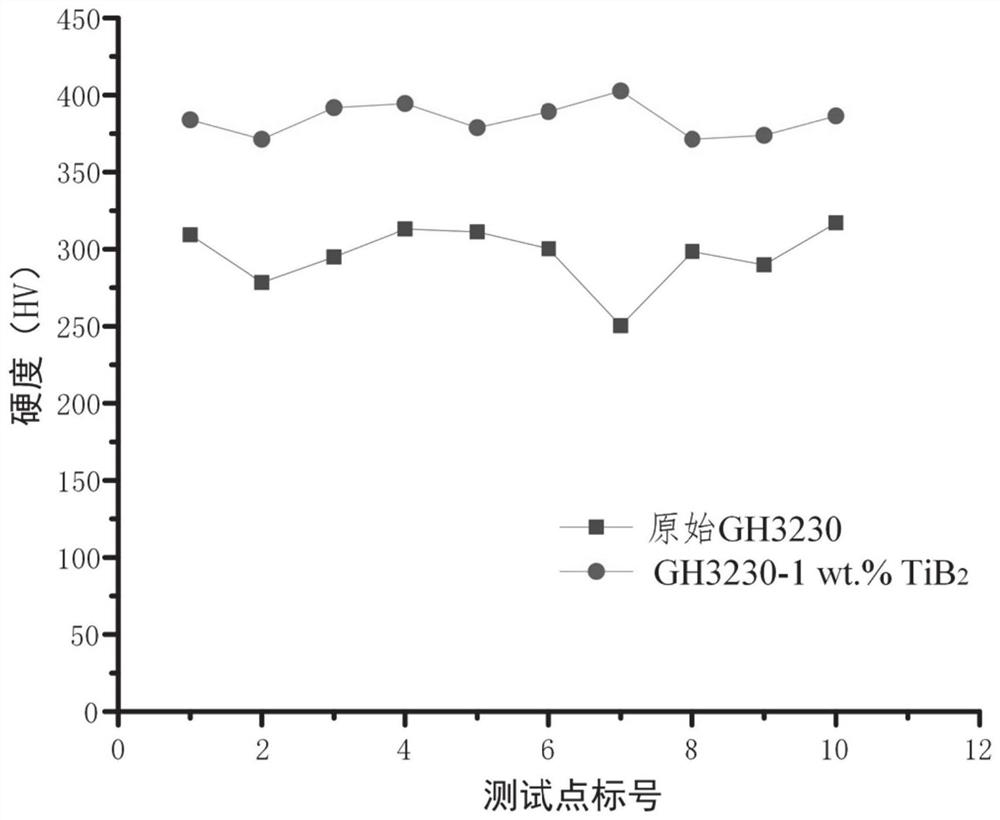

[0047] (1) Select GH3230 powder with an average particle size of 28.2μm and TiB with an average particle size of 500nm 2 Powder, according to the mass ratio of 99:1, prepared to contain 1.0wt.%TiB 2 composite powder.

[0048] (2) Then carry out double-centrifugal high-speed mixing and stirring for the composite powder, the mixing speed is 1500rpm, each time is 1 minute, after each mixing, cool for 20 minutes before the next mixing, until the powder is evenly mixed and there is no obvious agglomeration.

[0049] (3) Use the ConceptLaserMlab 200R metal additive manufacturing equipment to perform SLM forming on the composite powder obtained in the previous step. The detailed process parameters are as follows: laser power 190W, scanning speed 800mm / s,...

Embodiment 2

[0051] In this embodiment, a method for eliminating microcracks in laser selective melting forming GH3230 nickel-based superalloy is provided, including the following steps:

[0052] The specific preparation method is as follows:

[0053] (1) Select GH3230 powder with an average particle size of 35 μm and TiB with an average particle size of 800 nm 2 powder, respectively according to the mass ratio of 98.5:1.5, prepared to contain 1.5wt% TiB 2 composite powder.

[0054] (2) Then carry out double-centrifugal high-speed mixing and stirring for the composite powder, the mixing speed is 1500rpm, each time is 1 minute, after each mixing, cool for 20 minutes before the next mixing, until the powder is evenly mixed and there is no obvious agglomeration.

[0055] (3) Use the ConceptLaserMlab 200R metal additive manufacturing equipment to perform SLM forming on the composite powder obtained in the previous step. The detailed process parameters are as follows: laser power 200W, scanni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com