Different hydrogen fuel cell for a hydrogen -energy vehicle

A fuel cell and durability technology, applied in fuel cells, fuel cell parts, circuits, etc., to meet electrical performance requirements, avoid misalignment, and increase electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

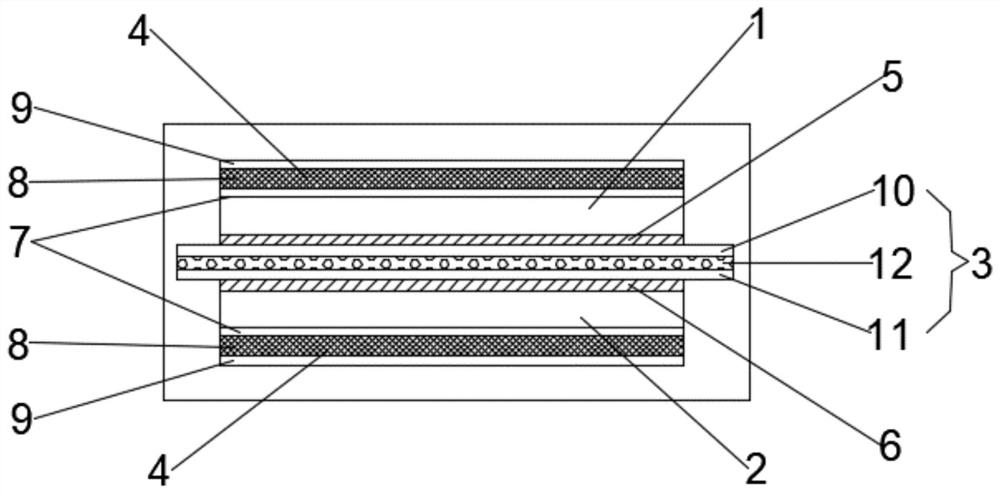

[0030] A durable hydrogen fuel cell for hydrogen vehicles, such as figure 1 As shown, it includes an anode plate 1, a cathode plate 2 and an electrolyte membrane 3. The electrolyte membrane 3 is arranged between the anode plate 1 and the cathode plate 2. The outer sides of the anode plate 1 and the cathode plate 2 are provided with a current collector plate 4. Two The collector plates 4 are arranged in parallel; a first glue film 5 is bonded between the anode plate 1 and the electrolyte membrane 3, and a second glue film 6 is glued between the electrolyte membrane 3 and the cathode plate 2;

[0031] Each of the current collecting plates 4 includes a stainless steel base layer 7 , an anti-corrosion intermediate layer 8 and a conductive anti-corrosion layer 9 which are sequentially arranged from the inside to the outside.

[0032] The first adhesive film 5 , the second adhesive film 6 and the electrolyte membrane 3 have the same shape and area, and both the first adhesive film 5...

Embodiment 2

[0048] A durable hydrogen fuel cell for hydrogen vehicles, such as figure 1 As shown, it includes an anode plate 1, a cathode plate 2 and an electrolyte membrane 3. The electrolyte membrane 3 is arranged between the anode plate 1 and the cathode plate 2. The outer sides of the anode plate 1 and the cathode plate 2 are provided with a current collector plate 4. Two The collector plates 4 are arranged in parallel; a first glue film 5 is bonded between the anode plate 1 and the electrolyte membrane 3, and a second glue film 6 is glued between the electrolyte membrane 3 and the cathode plate 2;

[0049] Each of the current collecting plates 4 includes a stainless steel base layer 7 , an anti-corrosion intermediate layer 8 and a conductive anti-corrosion layer 9 which are sequentially arranged from the inside to the outside.

[0050] The first adhesive film 5 , the second adhesive film 6 and the electrolyte membrane 3 have the same shape and area, and both the first adhesive film 5...

Embodiment 3

[0066] A durable hydrogen fuel cell for hydrogen vehicles, such as figure 1 As shown, it includes an anode plate 1, a cathode plate 2 and an electrolyte membrane 3. The electrolyte membrane 3 is arranged between the anode plate 1 and the cathode plate 2. The outer sides of the anode plate 1 and the cathode plate 2 are provided with a current collector plate 4. Two The collector plates 4 are arranged in parallel; a first glue film 5 is bonded between the anode plate 1 and the electrolyte membrane 3, and a second glue film 6 is glued between the electrolyte membrane 3 and the cathode plate 2;

[0067] Each of the current collecting plates 4 includes a stainless steel base layer 7 , an anti-corrosion intermediate layer 8 and a conductive anti-corrosion layer 9 which are sequentially arranged from the inside to the outside.

[0068] The first adhesive film 5 , the second adhesive film 6 and the electrolyte membrane 3 have the same shape and area, and both the first adhesive film 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com