Preparation and production method of paste

A technology for ointment and production equipment, applied in the field of ointment processing, can solve the problems of affecting the stability of drug efficacy, insufficient mixing of ointment raw materials, insufficient uniformity of ointment components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] Such as Figure 7-10 , On the basis of the above-described embodiments, the present invention is provided with composite parts on the feed electric roller 38; One side; the fitting plate 49 is arranged between the mounting frame 48 and the feeding electric roller 38; one end of the elastic pusher 50 is connected to the mounting frame 48, and the other end is connected to the bonding plate 49.

[0049] In an optional embodiment, the laminating plate 49 is an arc-shaped plate, and its concave end faces the feeding motorized roller 38 .

[0050] In an optional embodiment, the discharge port of the mixing chamber 5 is provided with a coating cooling assembly 10; The fourth driving motor 45, infrared detector 46 and air duct; the connecting frame 40 is arranged on the housing 1; the cooling seat 41 is arranged on the bottom end of the connecting frame 40, and there is a space between which the paste coating material passes through. Coating tank 51; the bottom of coating ta...

Embodiment 3

[0053] The present invention proposes a kind of ointment making production method again, and the steps are as follows:

[0054] S1. Add base material and medicament raw material into two prefabricated boxes 2 respectively;

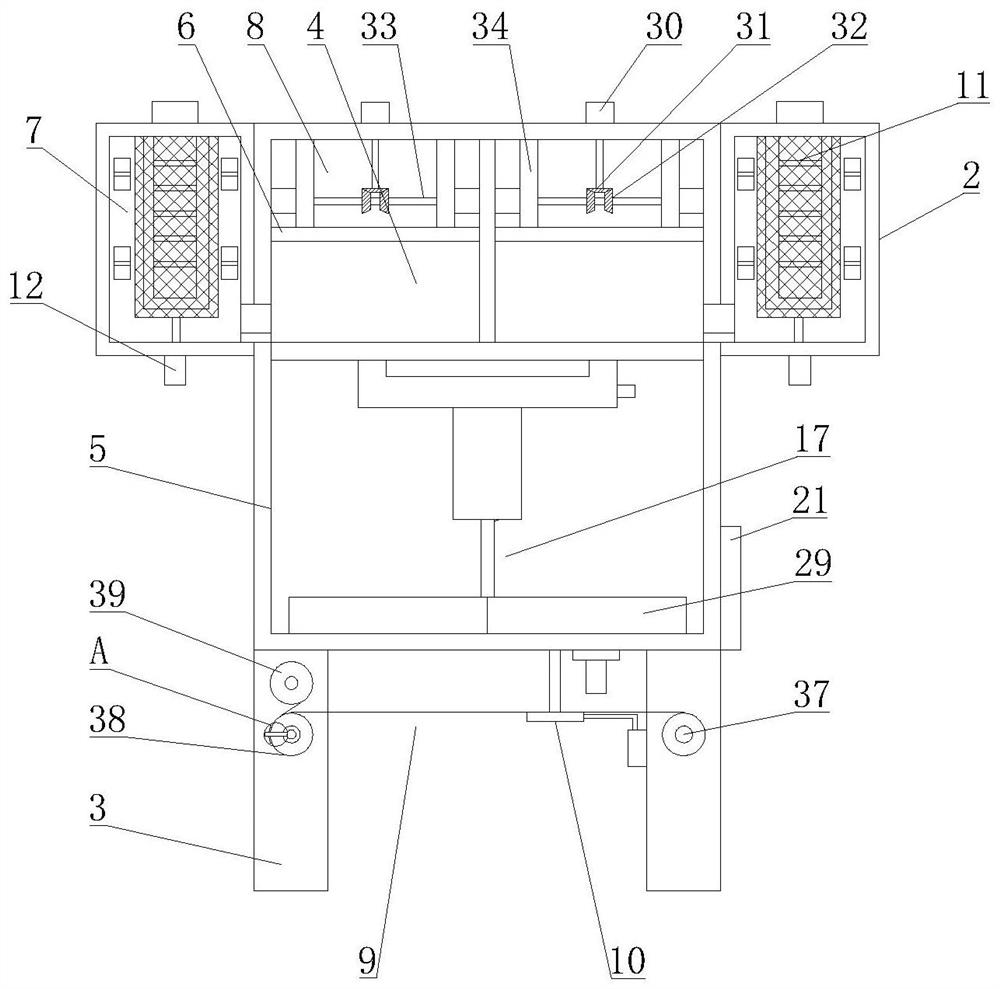

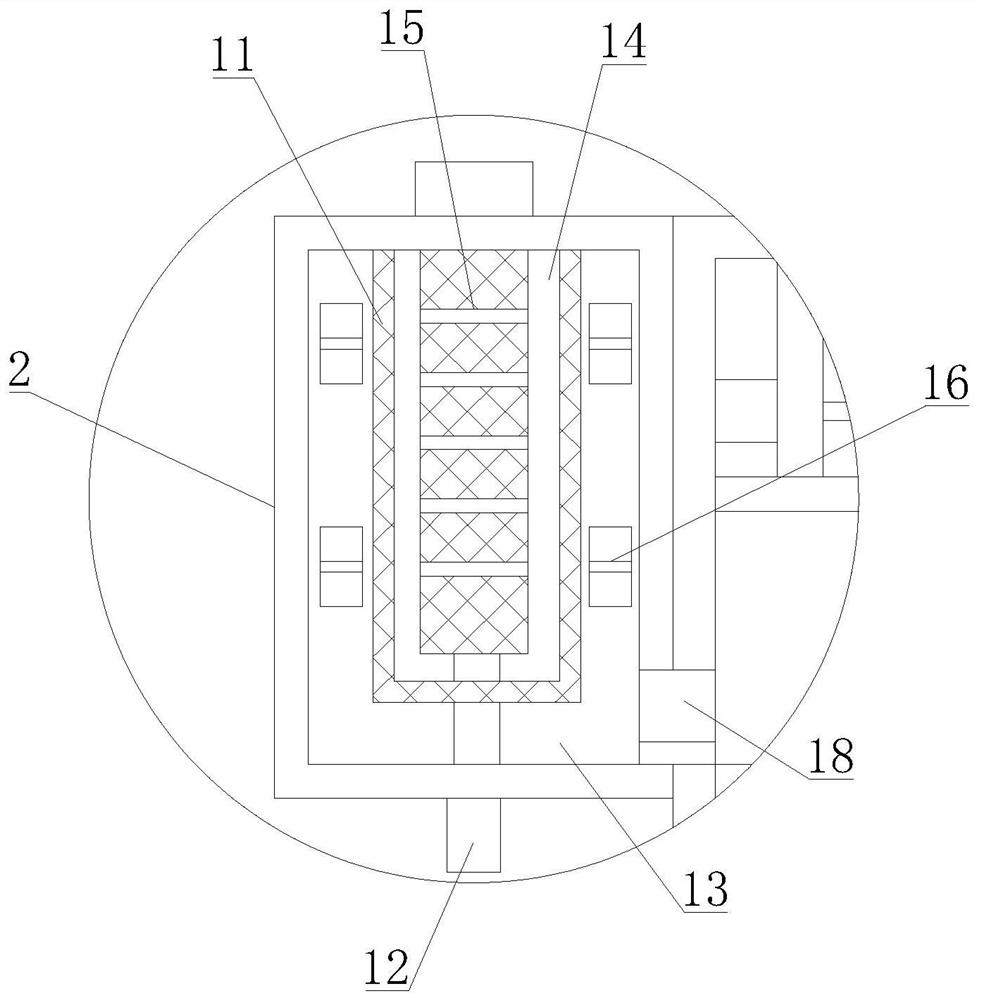

[0055] S2, through the action of the first mixing component 7, the outer mixing frame 13, the inner mixing frame 14 and the heating element 15 cooperate, the raw materials are melted, mixed and filtered, and set aside;

[0056] S3. According to the combination of the base material and the raw material of the medicine, adjust the corresponding dose adjustment assembly 8 respectively, and drive through the fourth rotating shaft 35 and the fifth rotating shaft 33, the eccentric wheel 34 rotates, and pushes the pushing plate 6 to move up, a certain amount The raw material enters the corresponding temporary storage chamber 4 through the first one-way valve 18, and the eccentric wheel 34 rotates in the opposite direction, pushing the pushing plate 6 to move down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com