Automatic tooth aligning method of internal tooth powerful gear honing machine

A gear honing machine, a powerful technology, applied in the direction of gear cutting machine, gear tooth manufacturing device, gear teeth, etc., can solve the problem that the gear honing machine cannot automatically align the teeth, and the manual tooth alignment cannot meet the machining accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

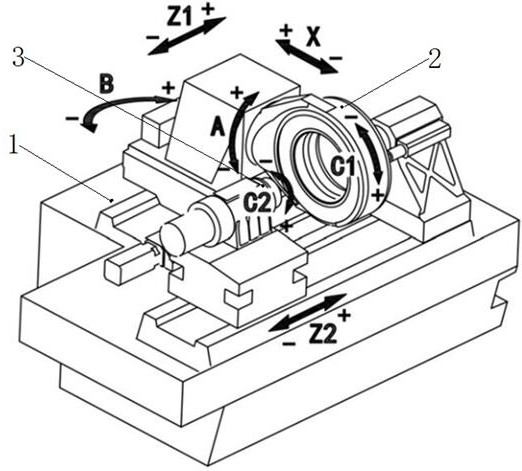

Image

Examples

Embodiment Construction

[0029] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

[0030] The invention discloses an automatic gear alignment method for a powerful internal gear honing machine, which comprises the steps of:

[0031] S01, first find out the theoretical relationship between the meshing center distance and the shaft angle of the honing wheel and the dressing wheel;

[0032] S02. Install a strain sensor on the feed shaft of the machine tool to measure the inner diameter of the honing wheel, calculate the pitch radius of the honing wheel according to the inner diameter and the theoretical tooth length of the honing wheel, and then combine the pitch radius of the dressing wheel to calculate Corresponding meshing center distance;

[0033] S03. Control the machine tool to drive the honing wheel and the dressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com