Subway operation line base long steel rail welding platform device and using method

A welding platform and operation line technology, applied in welding equipment, auxiliary equipment, auxiliary welding equipment, etc., can solve the problems of large investment in protection supervision, long construction period, and affecting train operation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

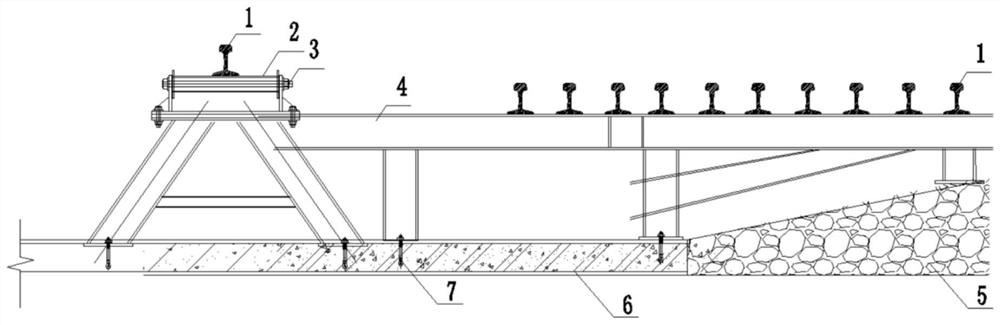

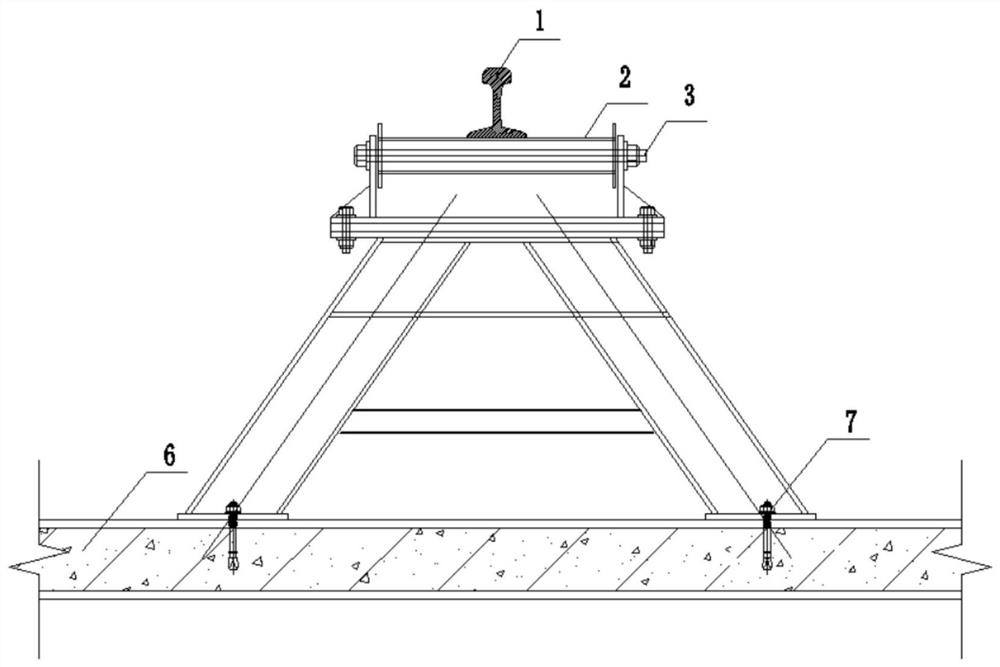

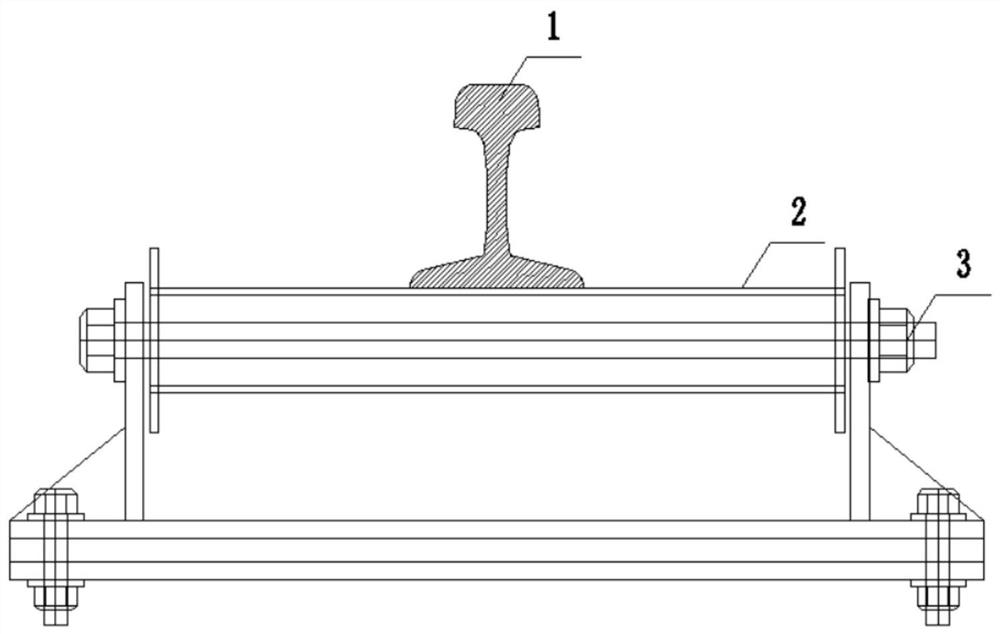

[0037] In this embodiment, using the existing subway vehicle base lines and the current situation, a long rail storage platform that meets the requirements of welding 25m rails into 100m is planned and constructed, including the welding operation area and the rail storage area. First, the 25m rails are welded in the welding operation area The 100m-long steel rail is formed, and then slides longitudinally through the roller shaft structure to the long rail storage area for transportation, and uses the subway outage time window to transport the 100m long steel rail to the underground line replacement site, and welds it into the replacement length for replacement in the selected time window.

[0038] Specifically, see Figure 5 As shown, the 25m rail is hoisted to the rail welding work area by a gantry crane with a span of 10m at the base, and two 25m long rails are welded with a rail welding machine, and then the rails are slid longitudinally through the roller shaft structure an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com