Anchor section joint of overhead rigid contact net for quick rail transit

A rail transit and rigid contact technology, applied in the field of rail transit, can solve the problems affecting the uniformity of the contact force of the pantograph, multiple touches, and the overlapping part cannot be too short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

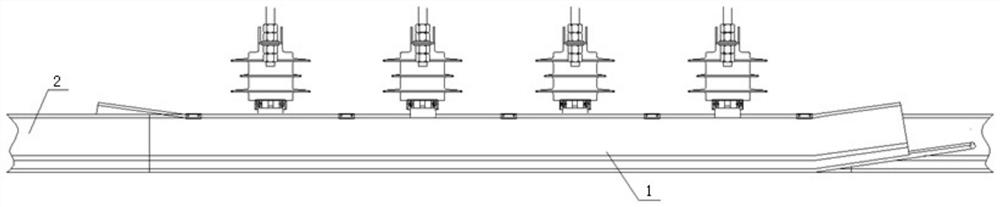

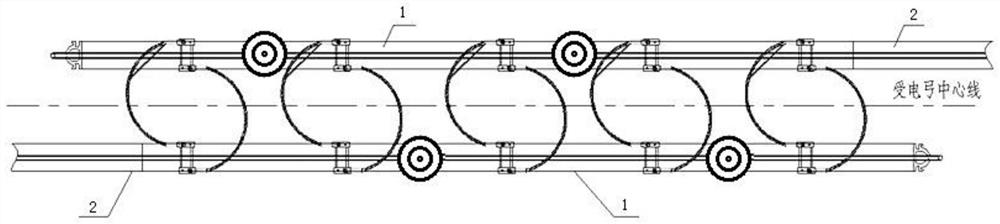

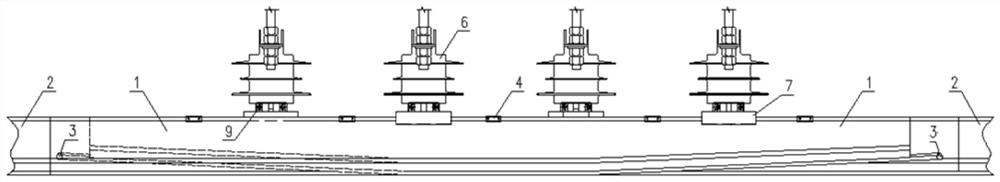

[0027] Embodiments of the present invention provide a rapid rail transit overhead rigid catenary anchor segment joint, such as Figure 3-7 As shown, it includes a busbar terminal 1 , a contact wire 3 , an electrical connection assembly and an insulator 6 . The two bus bar terminals 1 face opposite directions, are arranged in parallel and partially overlap each other, the contact wire 3 is fixed on the lower surface of the bus bar terminals 1 , and the bus bar terminals 1 are connected by an electrical connection component. The electrical connection assembly includes an electrical connection clamp 4 and an electrical connection wire 8, the electrical connection clamp 4 is fixed on the bus terminal 1, and the electrical connection c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com