Efficient and continuousaerobic bioreactor system

A reactor system, aerobic biology technology, applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical equipment, etc., can solve the problem of large floor area, low efficiency, and difficult material handling and other issues, to achieve the effect of improving efficiency and effect, saving floor space, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

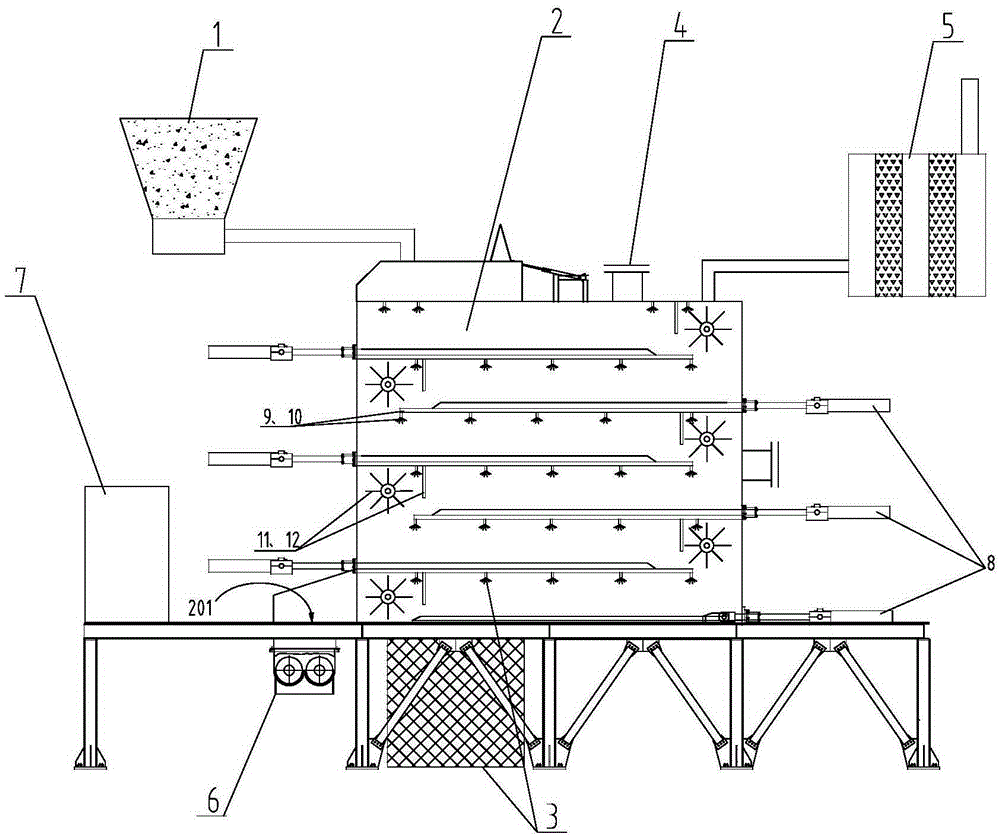

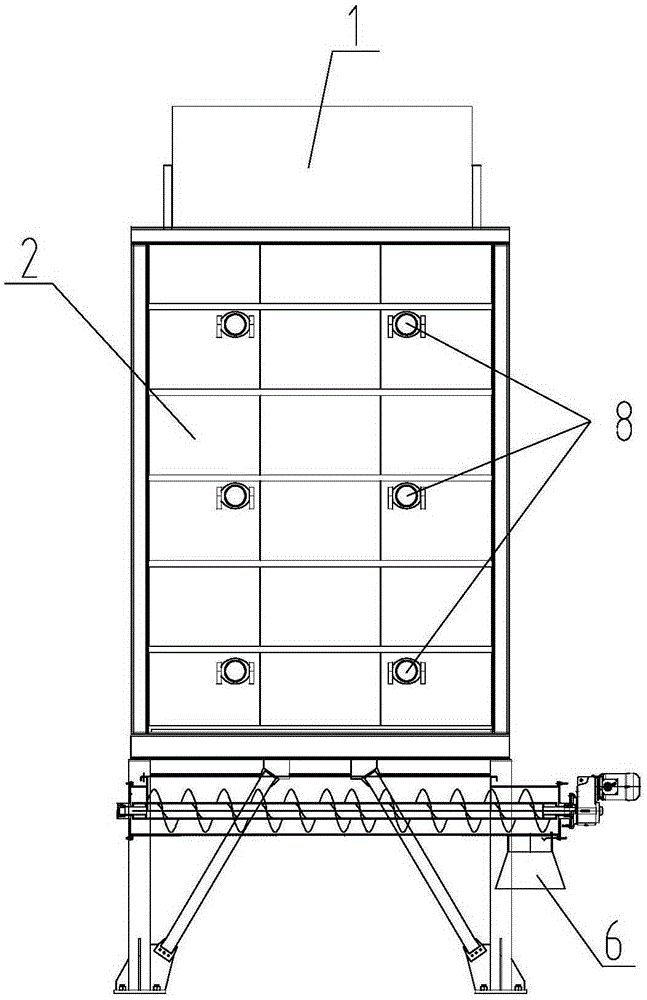

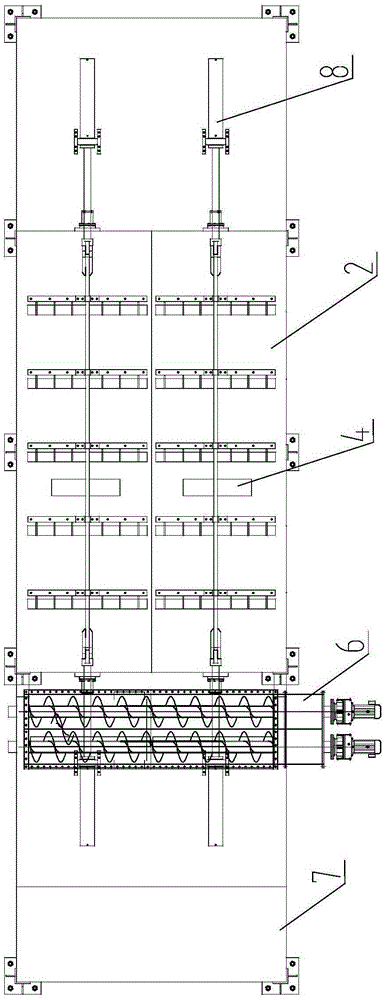

[0054] refer to Figure 1 to Figure 3 As shown, the high-efficiency continuous aerobic bioreactor system of the present invention is mainly composed of a feed unit 1, a silo unit 2, a discharge unit 6, a deodorization unit 5, a ventilation unit 4, a leachate collection spray unit 3 and an electrical control unit. Unit 7 consists of seven parts.

[0055] The output port of the feed unit 1 is connected to the feed port of the silo unit 2, and can be fed from the top of the silo unit 2 through conveying equipment such as a belt conveyor, a chain conveyor, a screw conveyor or a loader. material.

[0056] The silo unit 2 has a feed inlet and a feed outlet. The main unit (silo body) of the high-efficiency continuous aerobic bioreactor system is a rectangular three-dimensional structure or a concrete structure, and the whole can be arranged on the ground or underground. Or use the geographical features and needs of the project site to build according to local conditions. In this e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com