Diarylnonane Ⅱ and Ⅰ free radical inhibitors in Saxifrage tangutica and its separation, preparation and application

A technology of diaryl nonane and tangut saxifera, which is applied in the field of separation of diaryl nonane free radical inhibitors, can solve problems not involving diaryl nonane free radical inhibitors, and achieve low-cost separation The effect of average cost, low cost, and easy batch material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The separation and preparation process of diarylnonane class II and I free radical inhibitors in saxifrage tangutata specifically includes the following steps:

[0064] Step 1, extraction: dry 500g of saxifrage whole herb in the shade, coarsely crush it and extract it with methanol at a material-to-liquid ratio of 1g: 5mL, extract 4 times at room temperature for 2 hours each time, filter and combine the filtrates, namely filtrate A, The filtrate A is mixed according to the amount of polyamide: the amount of saxifrage tangutica medicinal material = 1:5 and then dried under reduced pressure. The conditions for drying under reduced pressure are: vacuum degree 50mbar, temperature 40°C, to obtain saxifrage tangutatus Grass extract mixed sample 160.2g;

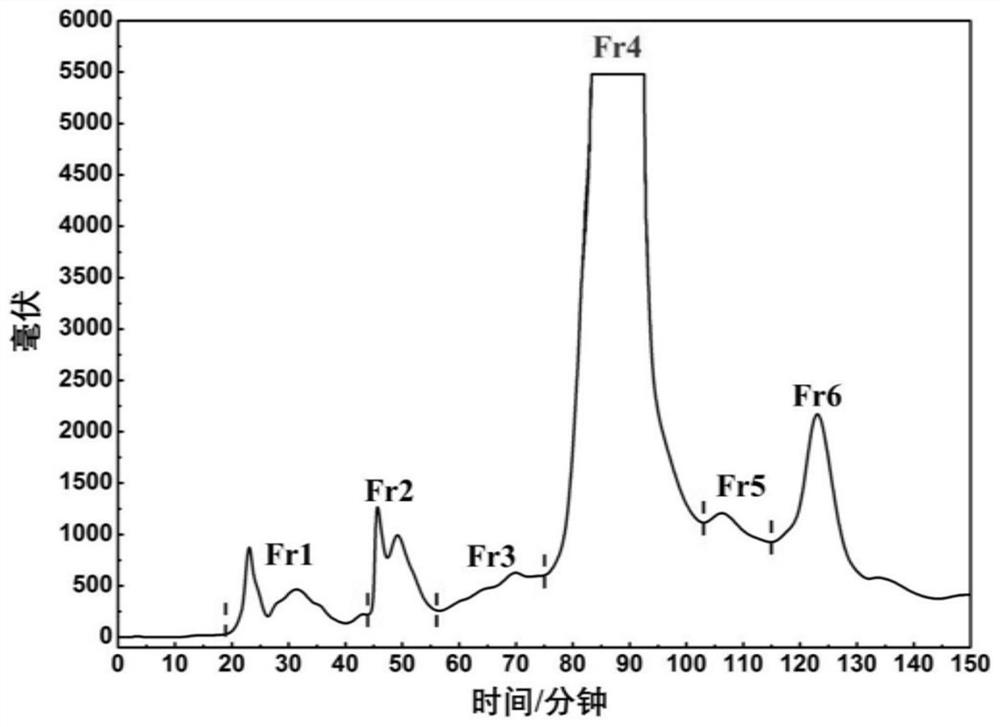

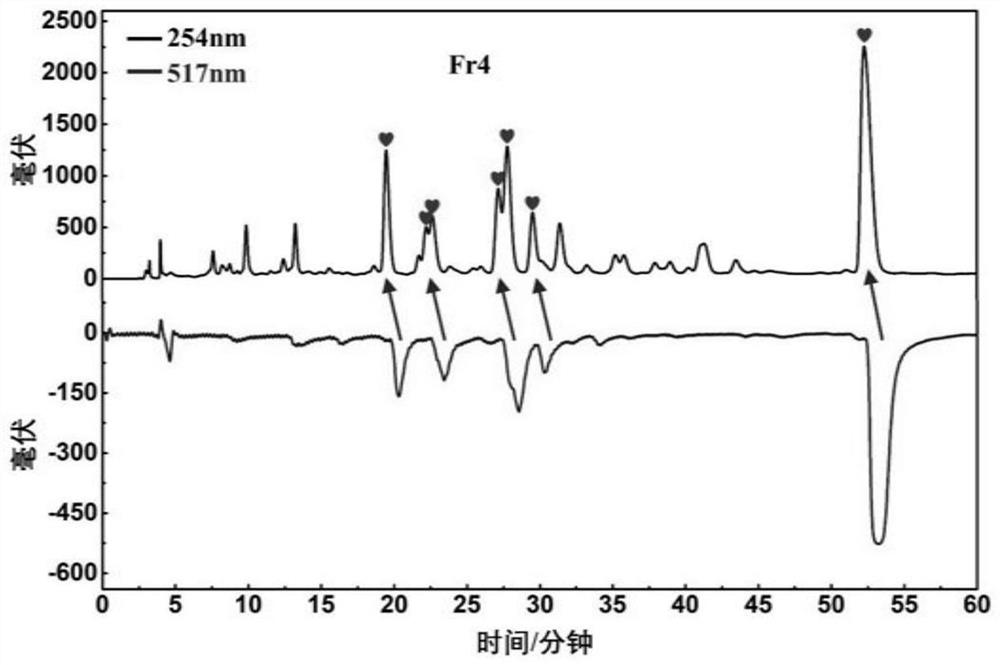

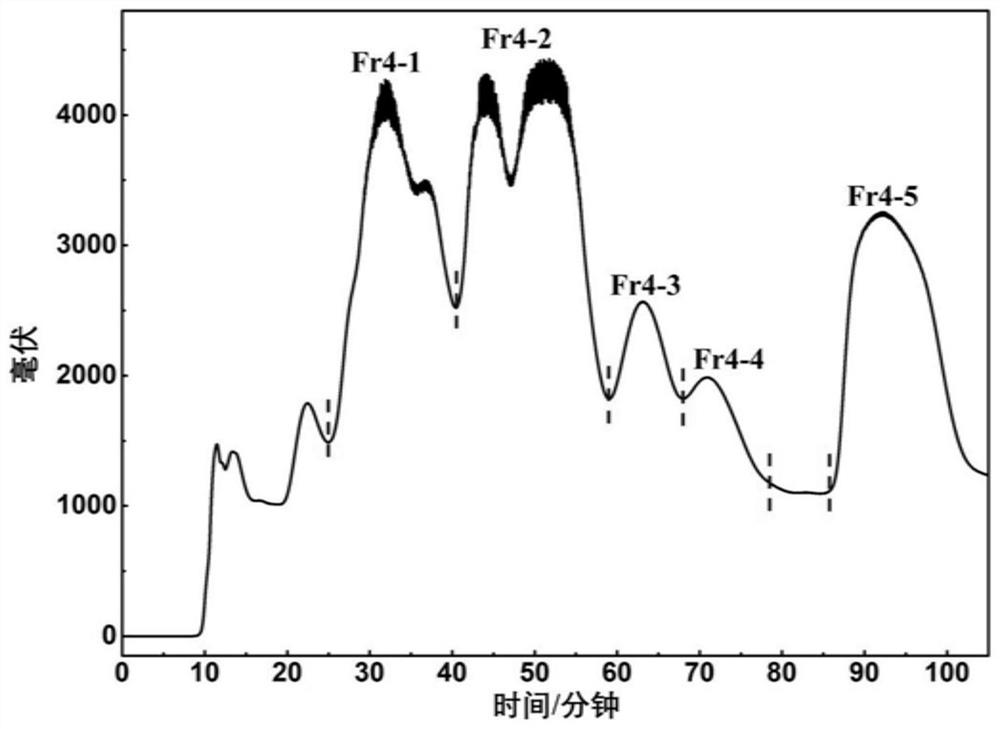

[0065] Step 2, coarse separation of microporous resin column: sample mixed with saxifrage extract of Tangutia tanguticae, the sample is separated by medium-pressure chromatography equipped with microporous resin, detected by ...

Embodiment 2

[0073] The separation and preparation process of diarylnonane class II and I free radical inhibitors in saxifrage tangutata specifically includes the following steps:

[0074] Step 1, extraction: dry 1000g of saxifrage whole herb in the shade, coarsely crush it and extract it according to the ratio of solid to liquid: 1g: 100mL of methanol, extract twice at room temperature, each time for 4h, filter and combine the filtrates, that is, filtrate A, The filtrate A is mixed according to the amount of polyamide: the amount of saxifrage tangutica medicinal material = 1:5 and then dried under reduced pressure, wherein the conditions for drying under reduced pressure are: vacuum degree 250mbar, temperature 60°C, to obtain saxifrage tangutatus Grass extract mixed sample 319.3g;

[0075] Step 2, coarse separation of microporous resin column: sample mixed with saxifrage extract of Tangutia tanguticae, the sample is separated by medium-pressure chromatography equipped with microporous res...

Embodiment 3

[0083] The separation and preparation process of diarylnonane class II and I free radical inhibitors in saxifrage tangutata specifically includes the following steps:

[0084] Step 1, extraction: dry 1200g of saxifrage whole herb in the shade, coarsely crush it and extract it according to the ratio of solid to liquid: 1g: 50mL of methanol, extract at room temperature 3 times, each time for 3h, filter and combine the filtrates, that is, filtrate A, The filtrate A is mixed according to the amount of polyamide: the amount of saxifrage tangutica medicinal material = 1:5 and then dried under reduced pressure, wherein the conditions for drying under reduced pressure are: vacuum degree 150mbar, temperature 50°C, to obtain saxifrage tangutatus Grass extract mixed sample 363.7g;

[0085] Step 2, coarse separation of microporous resin column: sample mixed with saxifrage extract of Tangutia tanguticae, the sample is separated by medium-pressure chromatography equipped with microporous re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com