Automobile paint with high drying speed

A drying speed, car technology, applied in the field of car paint, can solve the problems of high energy consumption, unsatisfactory car paint, long baking time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

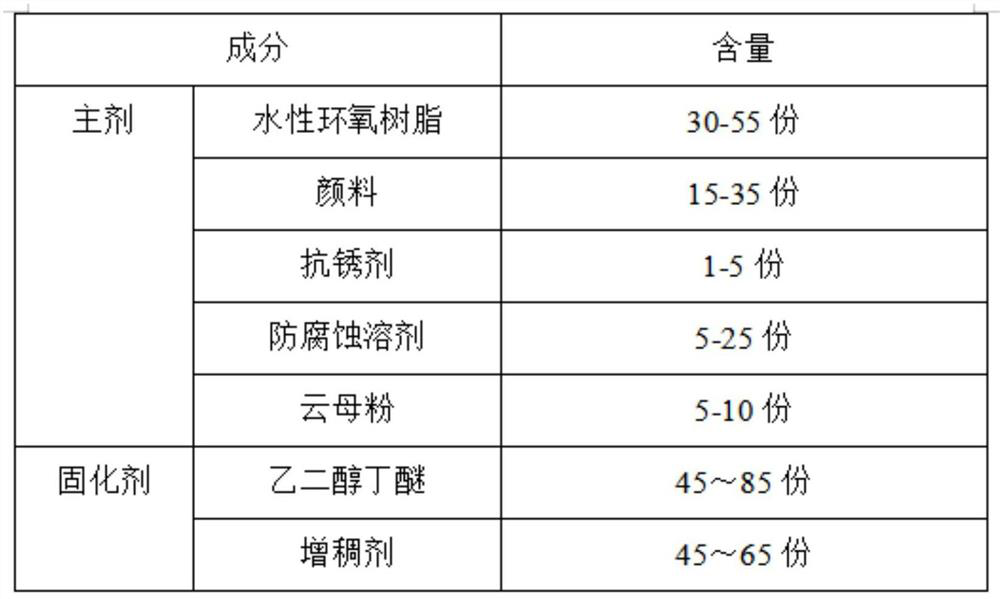

[0021] A car paint with fast drying speed. The car paint includes a main agent and a curing agent. The raw materials of the main agent and the curing agent are respectively in parts by volume: main agent components: water-based epoxy resin 30-55, Pigment 15-35, anti-rust agent 1-5, anti-corrosion solvent 5-25, mica powder 5-10; curing agent components: ethylene glycol butyl ether 45-85, thickener 45-65; the paint The volume ratio of the component and the curing agent component is 1-4:2.

[0022] A preparation method for automobile paint, the method comprises the following steps:

[0023] A: Preparation of paint components:

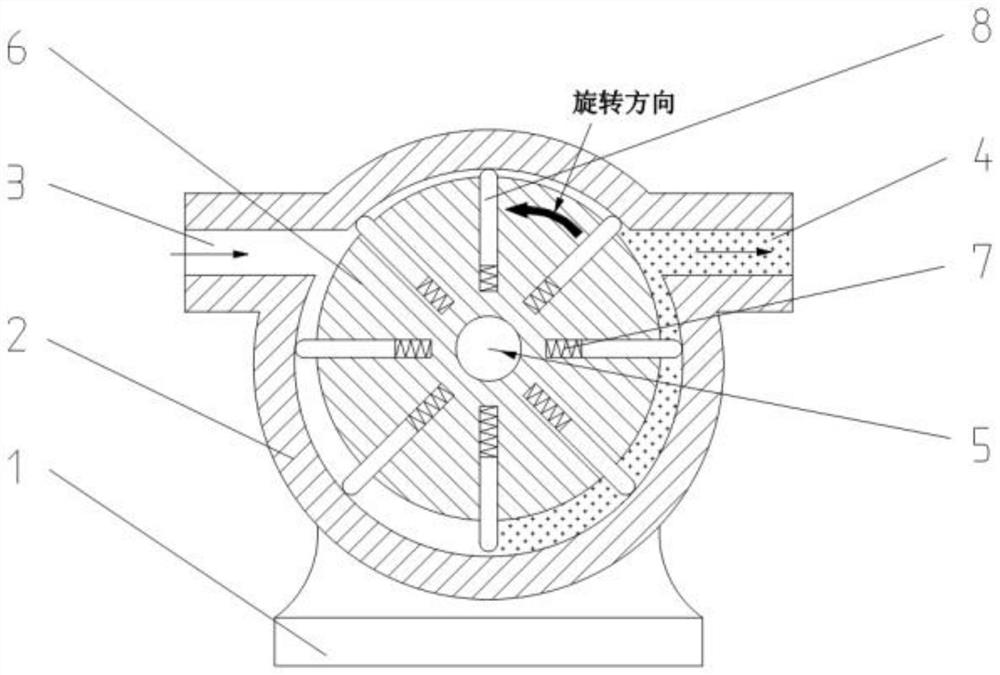

[0024] (1) Transport 10-25 parts of water-based epoxy resin, 1-5 parts of anti-rust agent, 5-25 parts of anti-corrosion solvent, and 5-10 parts of mica powder into the mixing tank through a single-part delivery pump, and stir evenly ;

[0025] (2) Add 15-35 parts of pigment while stirring, and disperse at high speed in the mixing tank for 1.5-2 hours; ...

Embodiment 2

[0042] A car paint with fast drying speed. The car paint includes a main agent and a curing agent. The raw materials of the main agent and the curing agent are respectively in parts by volume: main agent components: water-based epoxy resin 30-55, Pigment 15-35, anti-rust agent 1-5, anti-corrosion solvent 5-25, mica powder 5-10; curing agent components: ethylene glycol butyl ether 45-85, thickener 45-65; the paint The volume ratio of the component and the curing agent component is 1-4:2.

[0043] A preparation method for automobile paint, the method comprises the following steps:

[0044] A: Preparation of paint components:

[0045] (1) Transport 10-25 parts of water-based epoxy resin, 1-5 parts of anti-rust agent, 5-25 parts of anti-corrosion solvent, and 5-10 parts of mica powder into the mixing tank through a single-part delivery pump, and stir evenly ;

[0046] (2) Add 15-35 parts of pigment while stirring, and disperse at high speed in the mixing tank for 1.5-2 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com