Processing technology of high-wear-resistance cloth

A technology with high wear resistance and processing technology, applied in the field of fabric processing, can solve the problems of uneven wear resistance, decreased wear resistance, and insufficient wear resistance of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

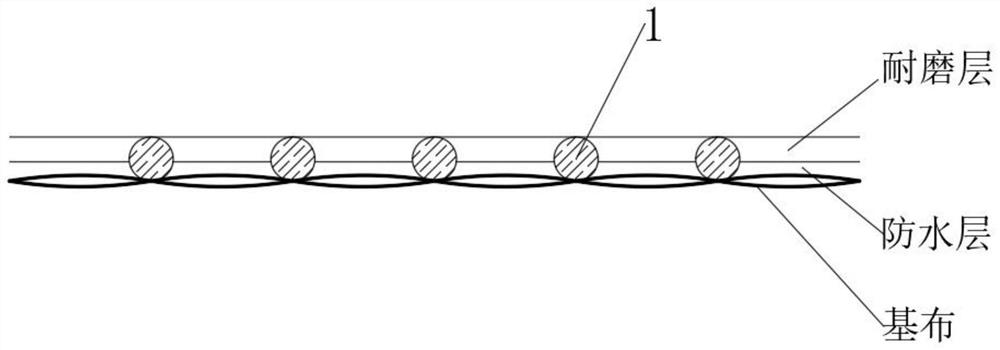

[0042] see figure 1 , a processing technology of high wear resistance cloth, comprising the following steps:

[0043] S1, blending cotton fiber and flax fiber to make warp yarn, and blending bamboo fiber and polyester fiber to make weft yarn;

[0044] S2, take warp yarn and weft yarn and weave to obtain fabric, soak in chitosan solution for 15min, dry after taking out to obtain base cloth;

[0045] S3. Make a waterproof rubber material, scrape it on the surface of the base cloth at a speed of 18m / min, then dry the rubber material at a drying temperature of 110°C and a drying time of 1 min;

[0046] S4. Squeeze and inlay a plurality of wear-resistant microspheres on the weave concave part of the base fabric before the waterproof rubber is completely dried, continue drying after the end, and remove the excess rubber to level off to form a waterproof layer;

[0047] S5. Make a wear-resistant rubber material, and then apply it to the surface of the waterproof layer for drying. T...

Embodiment 2

[0058] see figure 1 , a processing technology of high wear resistance cloth, comprising the following steps:

[0059] S1, blending cotton fiber and flax fiber to make warp yarn, and blending bamboo fiber and polyester fiber to make weft yarn;

[0060] S2, take warp yarn and weft yarn and weave to obtain fabric, soak in chitosan solution for 20min, dry after taking out to obtain base cloth;

[0061] S3. Make a waterproof rubber material, and scrape it on the surface of the base cloth at a speed of 19m / min, then dry the rubber material at a drying temperature of 120°C and a drying time of 2 minutes;

[0062] S4. Squeeze and inlay a plurality of wear-resistant microspheres on the weave concave part of the base fabric before the waterproof rubber is completely dried, continue drying after the end, and remove the excess rubber to level off to form a waterproof layer;

[0063] S5. Make a wear-resistant rubber material, and then apply it to the surface of the waterproof layer for d...

Embodiment 3

[0069] see figure 1 , a processing technology of high wear resistance cloth, comprising the following steps:

[0070] S1, blending cotton fiber and flax fiber to make warp yarn, and blending bamboo fiber and polyester fiber to make weft yarn;

[0071] S2, take warp yarn and weft yarn and weave to obtain fabric, soak in chitosan solution for 25min, dry after taking out to obtain base cloth;

[0072] S3. Make a waterproof rubber material, scrape it on the surface of the base cloth at a speed of 20m / min, then dry the rubber material at a drying temperature of 130°C and a drying time of 3 minutes;

[0073] S4. Squeeze and inlay a plurality of wear-resistant microspheres on the weave concave part of the base fabric before the waterproof rubber is completely dried, continue drying after the end, and remove the excess rubber to level off to form a waterproof layer;

[0074] S5. Make a wear-resistant rubber material, and then apply it to the surface of the waterproof layer for dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com