Construction process for enhancing durability of toll station square road

A construction technology and durability technology, which is applied in the field of construction technology to enhance the durability of roads in toll plazas, and can solve problems such as stone falling, crushing, and asphalt film damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

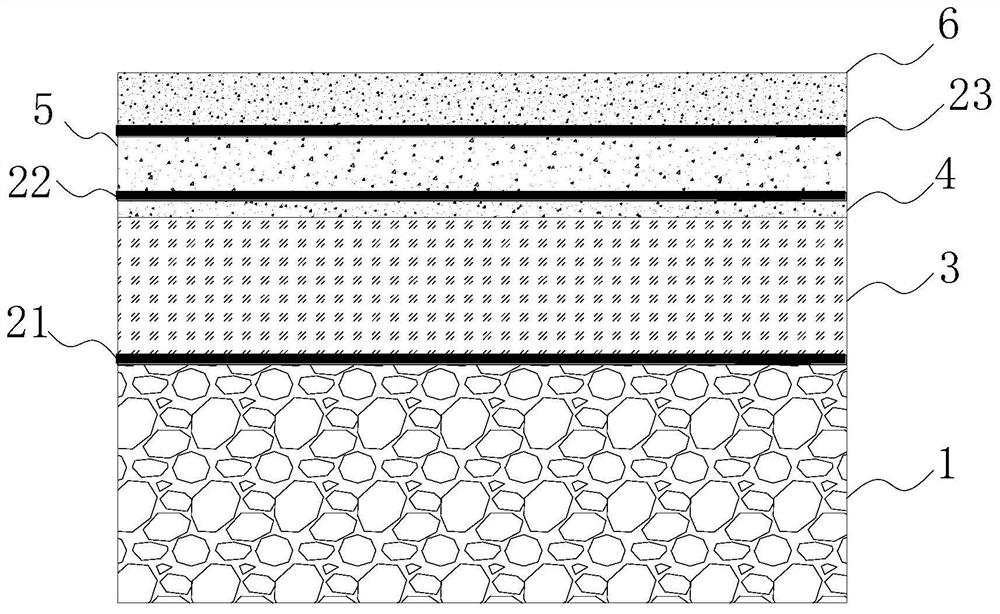

[0024] The present invention will be described in further detail below in conjunction with the embodiment given with accompanying drawing.

[0025] A construction technique for enhancing road durability of toll plaza, comprising the following steps:

[0026] S1: Laying roadbed 1;

[0027] S2: After cleaning the surface of the subgrade 1, spray the first asphalt bonding layer 21, and then lay the cement-stabilized macadam layer 3 on the first asphalt bonding layer 21; the cement-stabilized macadam layer 3 is a semi-rigid material and can be used as its upper part The stress transition between the flexible asphalt material and the lower rigid roadbed material acts as a buffer for the stress on the road base, thereby avoiding cracks in the road base due to excessive pressure impact, and at the same time avoiding cracks in the road surface;

[0028] S3: Lay the asphalt waterproof layer 4 on the cement-stabilized gravel layer 3; spray the asphalt waterproof layer 4 to prevent rain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com