Long-service-life and light-weight magnetofluid dynamic sealing device

A magnetic fluid dynamic sealing and lightweight technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of weakening the magnetic field gradient, increasing the pressure difference force, and increasing the radial gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

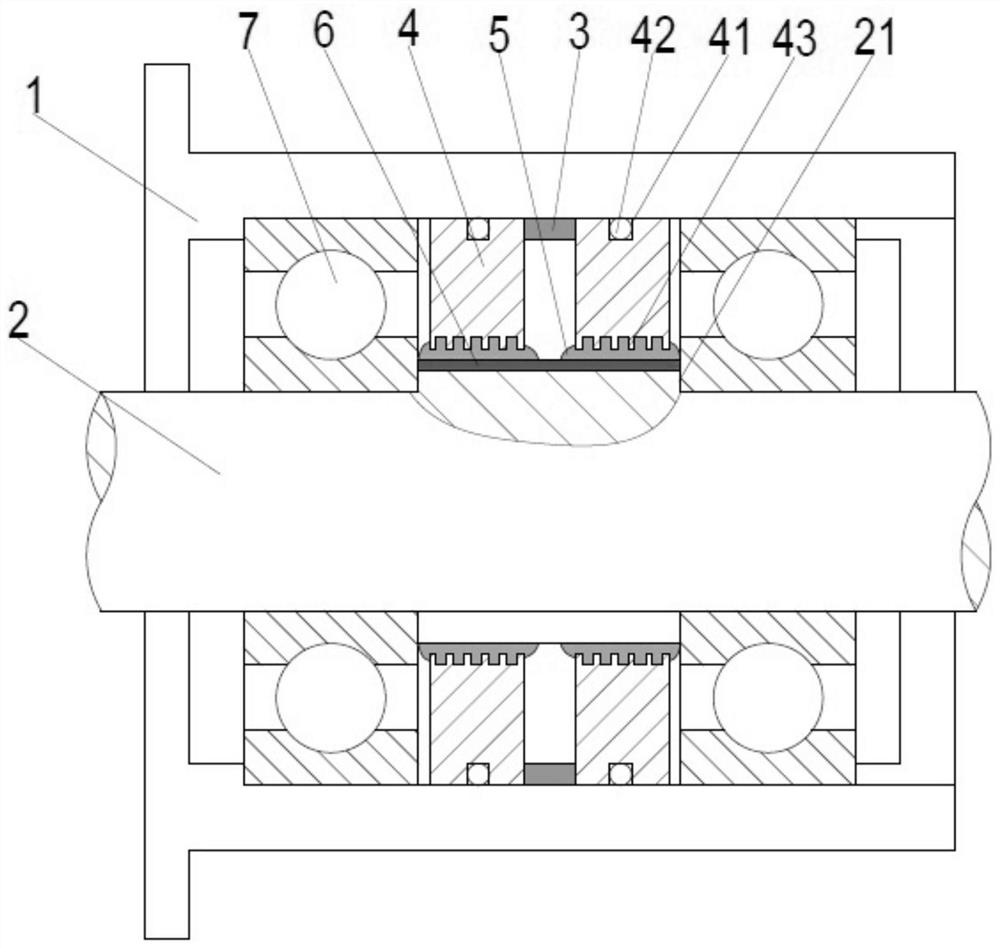

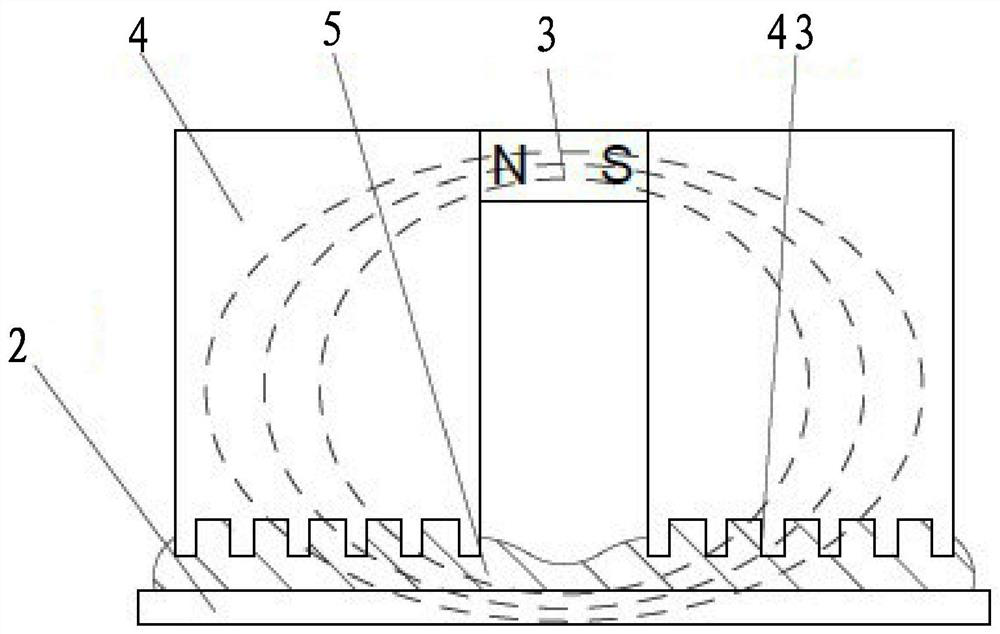

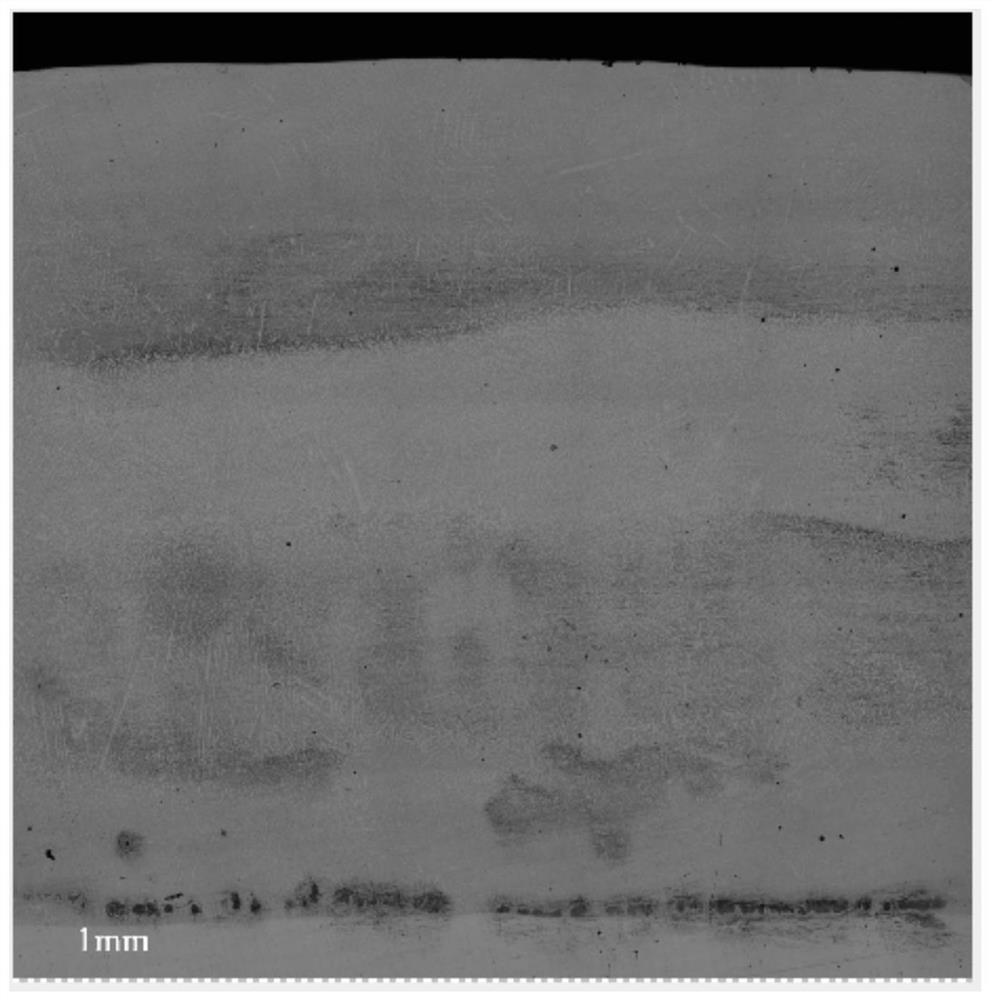

[0025] refer to figure 1 , figure 2 and Figure 5 , this embodiment relates to a long-life, lightweight magnetohydrodynamic sealing device, including a housing 1, a rotating shaft 2, a permanent magnet 3 and a pole piece 4 disposed in the housing 1, and the rotating shaft 2 is rotatably mounted on the housing On the body 1, the permanent magnet 3 is arranged on the inner wall of the housing 1, and the pole shoes 4 are arranged on both sides of the permanent magnet 3 on the inner wall of the housing 1; The inner wall is sealed and connected, there is a gap between the inner circumference of the pole piece 4 and the outer surface of the rotating shaft 2, and the gap is filled with magnetic fluid 5; the rotating shaft 2 is made of alloy material, and the outer circumference of the rotating shaft 2 is provided with a wear-resistant Coating 6; permanent magnet 3 generates magnetic induction lines passing through pole piece 4, magnetic fluid 5 and wear-resistant magnetically perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com