Photoelasticity test system and method based on optical amplification technology

An optical amplification and testing system technology, which is applied in optics, optical components, and the measurement of the change force of the optical properties of the material when it is stressed, can solve the problem of high stress in material damage, indistinguishable number of stripes, concentration, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

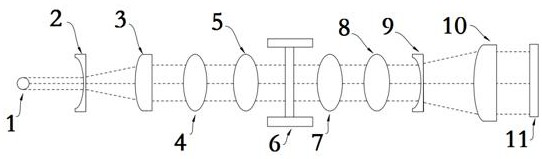

[0035] Such as figure 1 As shown, the photoelasticity testing system based on optical amplification technology in this embodiment includes a laser output unit 1 for providing the light source required for the field of view, and the first lens is sequentially arranged along the optical path direction output by the laser output unit 1 from front to back. group, photoelasticity test unit, second lens group and image acquisition unit 11. Among them: the first lens group is used to expand and collimate the beam at the exit of the laser output unit; the photoelastic test unit includes a polarizer 4, a first λ / 4 wave plate 5, a loading unit 6, a second The λ / 4 wave plate 7 and the analyzer 8 are used to realize the photoelastic optical path to obtain the arithmetic fringes; the second lens group is used to amplify the image, and the image acquisition unit is used to take the photoelastic image.

[0036] The optical path of the photoelastic test of the present invention is arranged a...

Embodiment 2

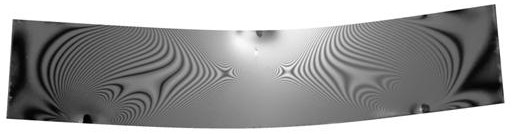

[0053] This embodiment provides a method for distinguishing fine and dense photoelastic arithmetic fringes, and the device is set up from front to back: laser output unit, first concave lens, first convex lens, polarizer, first λ / 4 wave plate, loading unit , the second λ / 4 wave plate, the analyzer, the second concave lens, the second convex lens and the CCD camera, and make the centers of each device be located at the same height of a straight line; adjust the frequency of the laser output device to make it and the CCD camera The frequencies are the same, and the beam expanded by the first lens group completely covers the object to be tested; the polarization direction of the polarizer is adjusted, and the fast and slow axes of the first λ / 4 wave plate and the second λ / 4 wave plate are adjusted to The angle between the polarizing directions of the polarizer and the analyzer is 45°; turn on the laser output unit, and place the test piece loaded on the loading unit in the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com