Heating element, and preparation method thereof and electric heater

A heating element and electric heating technology, applied in the field of electric heaters, can solve the problems of short heat transfer distance, poor economy, poor heat storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

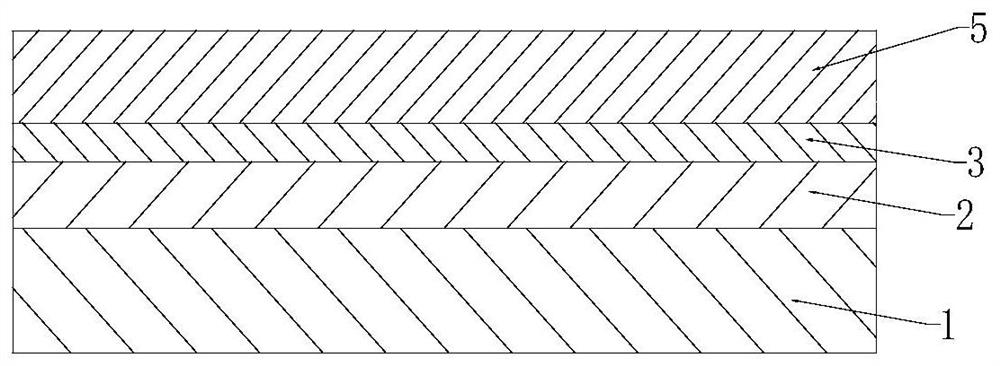

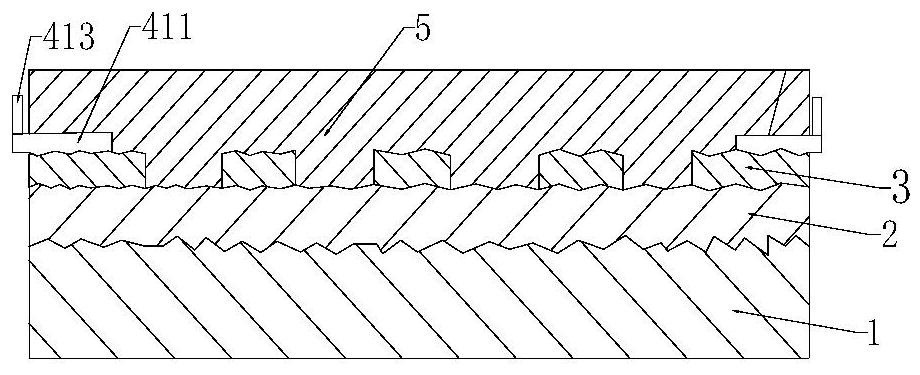

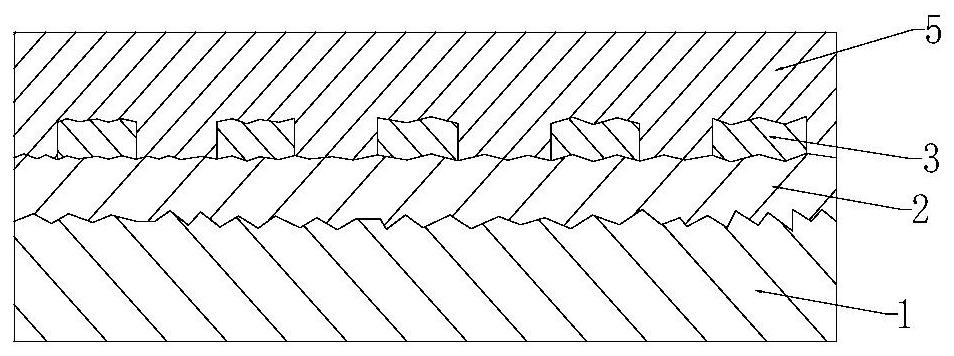

[0076] Thermal spraying on a stainless steel substrate to form a thickness of 200 microns, a porosity of less than 2%, and a specific heat capacity of 0.75×10 3 J / (kg*K) aluminum oxide insulating heat storage layer; on the surface of the aluminum oxide insulating heat storage layer away from the stainless steel substrate, spraying forms a FeCrAl heating layer with a thickness of 50 microns (the atomic percentage of oxygen is 25at%, power density 50w / cm 2 ); then print and form silver electrodes (comprising the first electrode and the second electrode) on the surface of the heat generating layer away from the stainless steel base material, and then spray on the surface of the aluminum oxide insulating heat storage layer away from the stainless steel base material to form a covering heat generating layer, Infrared heat storage layer with a single-layer structure (containing alumina and infrared emitting coatings, with a thickness of 300 microns and a specific heat capacity of 1....

Embodiment 2

[0077] Same as Example 1, the difference is that the infrared heat storage layer has a double-layer structure, including an alumina ceramic layer (thickness is 200 microns, porosity Less than 2%, the specific heat capacity is 0.8×10 3 J / (kg*K)), and an infrared emitting layer (thickness 300 microns) located on the surface of the alumina layer ceramic layer away from the substrate. Among them, the arithmetic average deviation of the interface profile of the stainless steel substrate and the alumina insulating heat storage layer is 30 microns, the arithmetic mean deviation of the interface profile of the alumina insulating heat storage layer and the heating layer is 25 microns, and the alumina ceramic layer and The arithmetic mean deviation of the profile of the interface profile between the heat generating layer is 20 microns, the arithmetic mean deviation of the profile of the interface profile between the alumina ceramic layer and the insulating heat storage layer of the alum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com