Fluidized bed hydrogenation reactor and use method thereof

A technology of hydrogenation reactor and ebullating bed, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of low separation accuracy and efficiency, insufficient driving force for cyclone separation enhancement, and inability to realize fully mixed flow operating conditions, etc. problems, to achieve high reaction space utilization, low heat loss, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

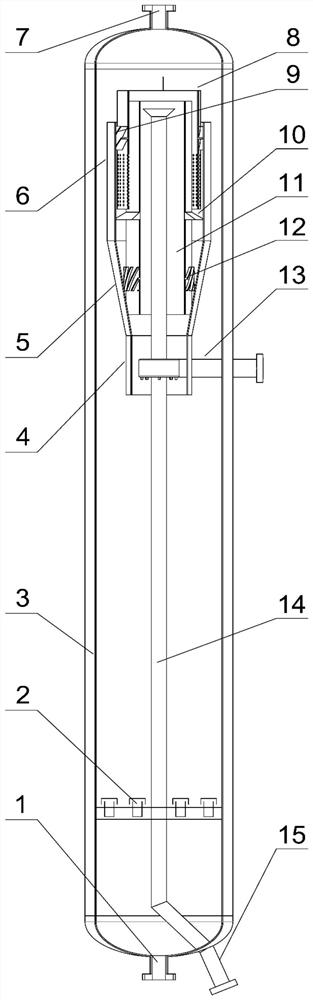

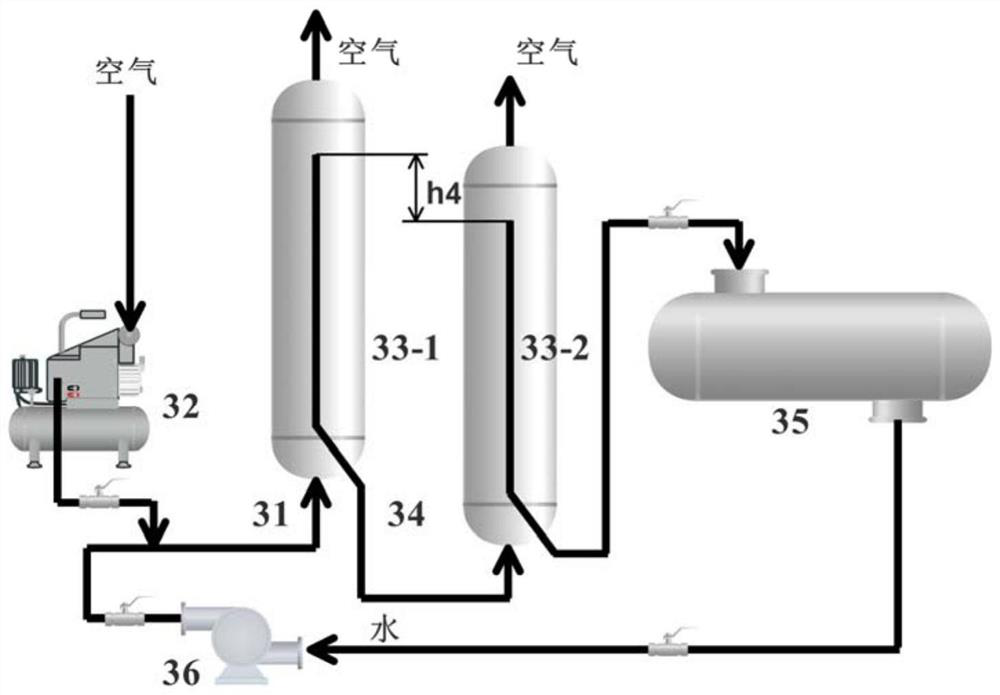

[0079] The boiling bed hydrogenation reactor was used for the cold die experiment of 3000 l / h boiling bed hydrogenation reactor.

[0080] Process

[0081] Such as image 3 Indicated.

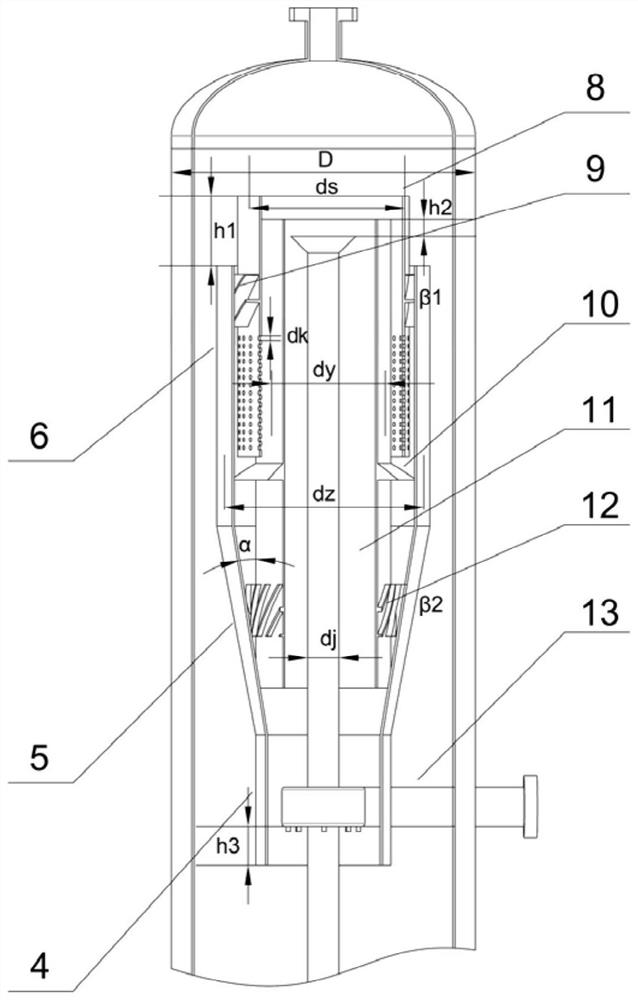

[0082] 2. Main structural dimensions of boiling bed hydrogen separators

[0083] The main structural dimensions of the boiling bed hydrogenation reactor are shown in Table 1, the two-stage boiling bed hydrogenation separator size structure is completely consistent.

[0084] Table 1: 3000L / h boiling bed hydrogenation reactor cold mold device structure size

[0085]

[0086] 3. Implementation effect

[0087] The test process of 3000L / h boiling bed hydrofolding device was tested using water and air, and the test results were shown in Table 2 below. From the experimental results, the catalyst reached uniform fluidization, continuous operation of 30 hours without failure, and 0.1 mM catalyst band is controlled less than 2 μg / g.

[0088] Table 2: 3000L / h boiling bed hydrocarbon cooling device t...

Embodiment 2

[0091] The boiling bed hydrogenation reactor is used for the hydrogenation deoxidation apparatus of 20000l / h straw hot solution.

[0092] Process

[0093] Such as Figure 4 Indicated.

[0094] 2. Boiling bed hydrogenation reactor main structural dimensions

[0095] The main structural dimensions of the boiling bed hydrogenation reactor are shown in Table 3, the two-stage boiling bed hydrogen separator size is completely consistent.

[0096] Table 3: 20000L / h stain straw tellement hydrogenation deoxygenation device boiling bed reactor structure size

[0097]

[0098] 3. Implementation effect

[0099] The test process of 20000l / h stain straw tellement hydrogenation deoxygenation unit was tested by straw pyrolysis, and the test results were shown in Table 4 below. From the experimental results, the catalyst reached uniform fluidization, continuous operation of 2000 hours without reactor coking, 0.1 mM catalyst band output control less than 2.5 μg / g.

[0100] Table 4: 20000L / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com