Welding method for secondary degassing sealing of ultrathin vapor chamber

A welding method and technology of soaking plate, applied in welding equipment, welding equipment, laser welding equipment, etc., can solve problems such as poor sealing performance, and achieve the effect of reducing processing cost and improving heat transfer performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below.

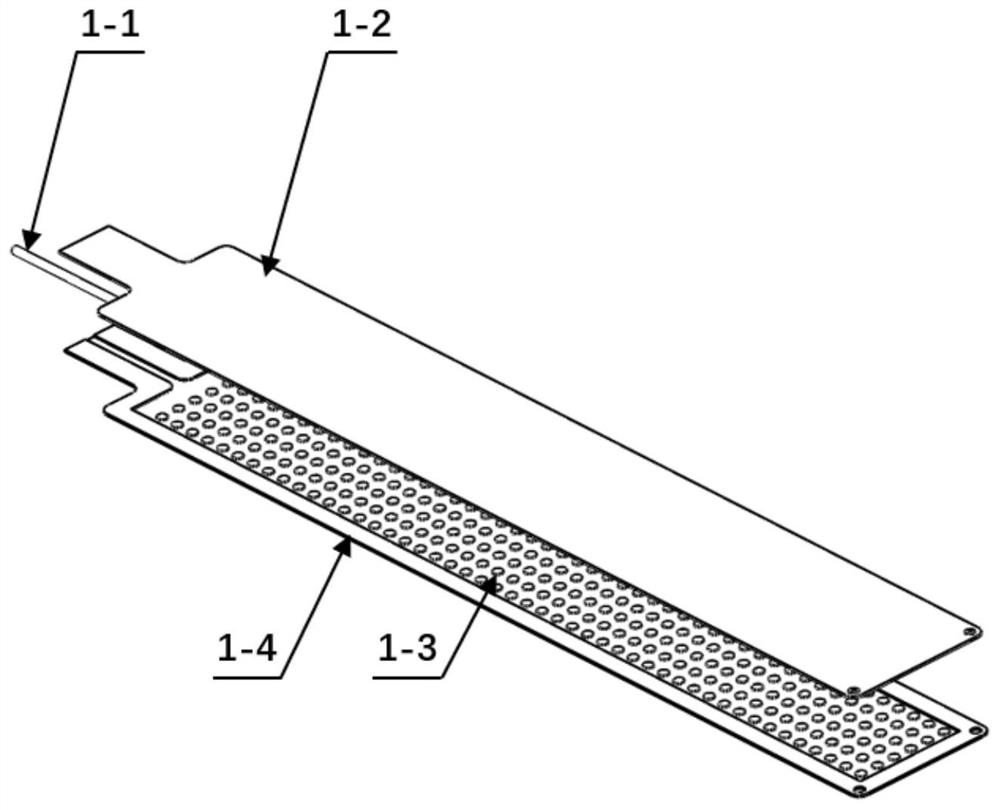

[0032] Such as Figure 5 , Figure 6 As shown, a welding method for secondary degassing sealing of ultra-thin vapor chamber 1 comprises the following steps,

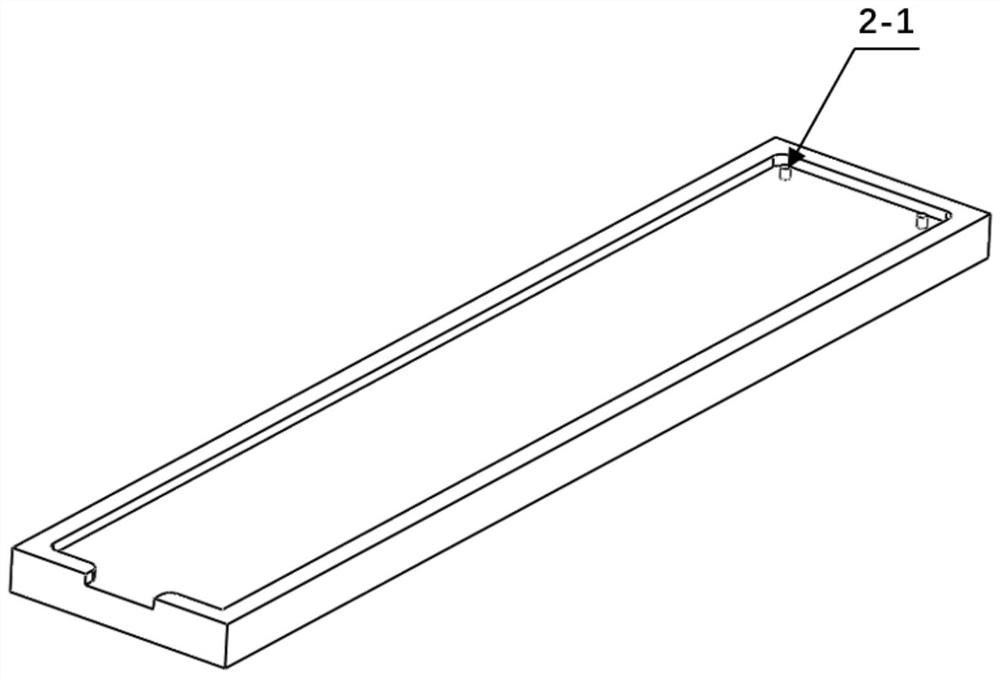

[0033] Utilize clamp 2 to fix the ultra-thin vapor chamber 1;

[0034] Use a pressure welding tool to perform pressure welding on the sealing part of the ultra-thin vapor chamber 1;

[0035] A laser welding tool is used to perform laser welding on the sealing part of the ultra-thin vapor chamber 1 .

[0036] In the existing welding method of the ultra-thin chamber 1 for secondary degassing and sealing, the sealing performance of the ultra-thin chamber 1 decreases after welding and sealing, resulting in a decrease in the heat transfer efficiency of the ultra-thin chamber 1, and the welding cost is high and the process Complicated, not conducive to mass production.

[0037] The welding method for secondary degassing and sealing of ultra-thin vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com