Automatic packaging roll for crops and manufacturing method of automatic packaging roll

A production method and technology for crops, applied in the directions of packaging, wrapping paper, flexible covering, etc., can solve the problems of complex materials and processes, and achieve the effect of shortening production time and reducing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

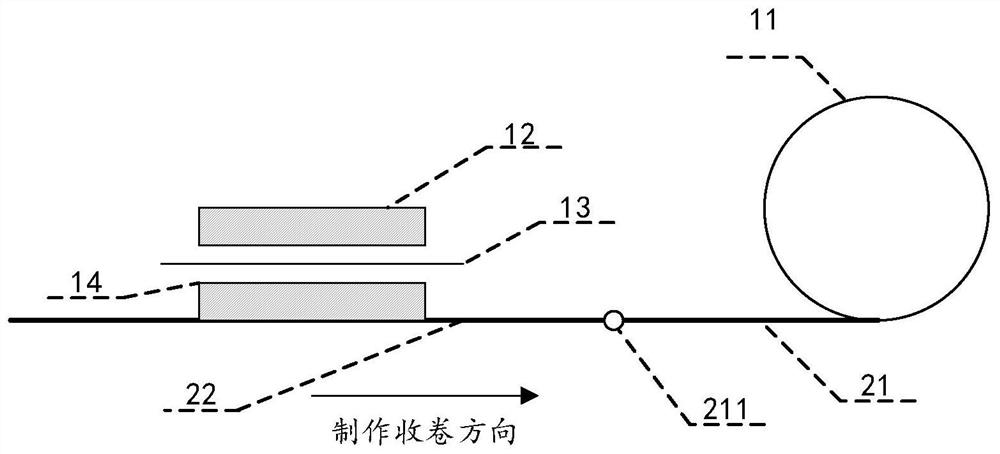

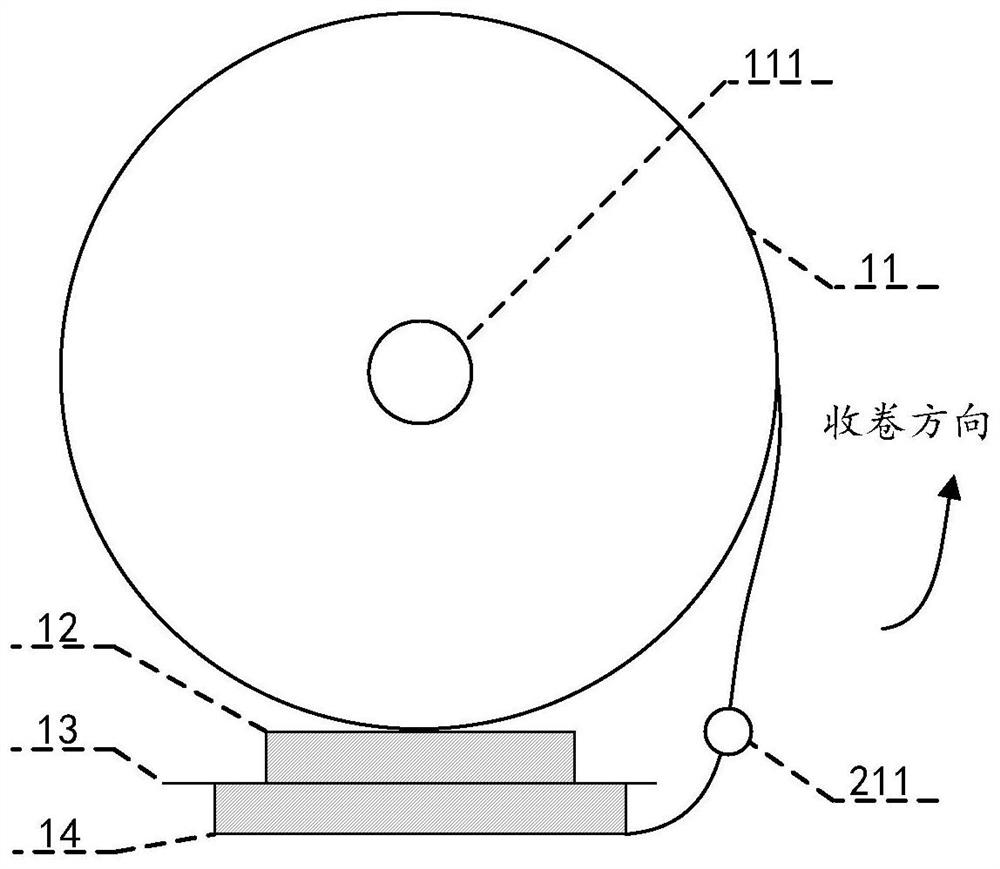

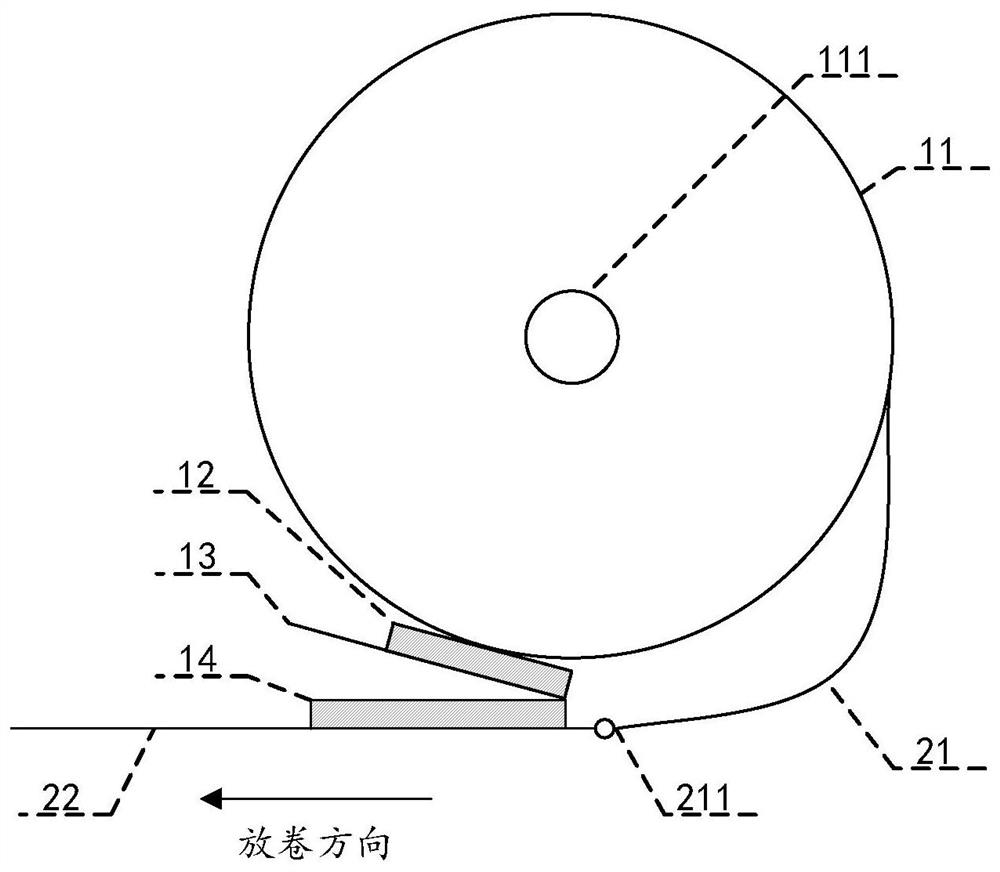

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] The present invention simplifies these complex processes to only use two pieces of double-sided adhesive tape to install on one side of the dividing line 211, and utilize the contact during winding to connect the front and rear units naturally. When unwinding, the circular rotation force is also automatically used to separate the double-sided adhesive tape and the release film 13 at the tangent point of the circumference, so that the double-sided adhesive tape on the two units is separated. When unwinding, the separation directions of the two double-sided adhesive tapes at the circumferential tangent point are opposite, so the single release film 13 can be eas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com