Motorcycle tire final assembly unstacking and conveying method

A motorcycle and tire technology, applied in the direction of conveyors, destacking of objects, conveyor objects, etc., can solve unsolved automatic and intelligent production destacking and transportation of motorcycle tires, continuous operation and holding of undisclosed batches of tires. Tire fastening technology solution, lack of single tire positioning, push and special conveying components and other problems, to achieve the effect of simple and sophisticated equipment structure, continuous production, improved accuracy and automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

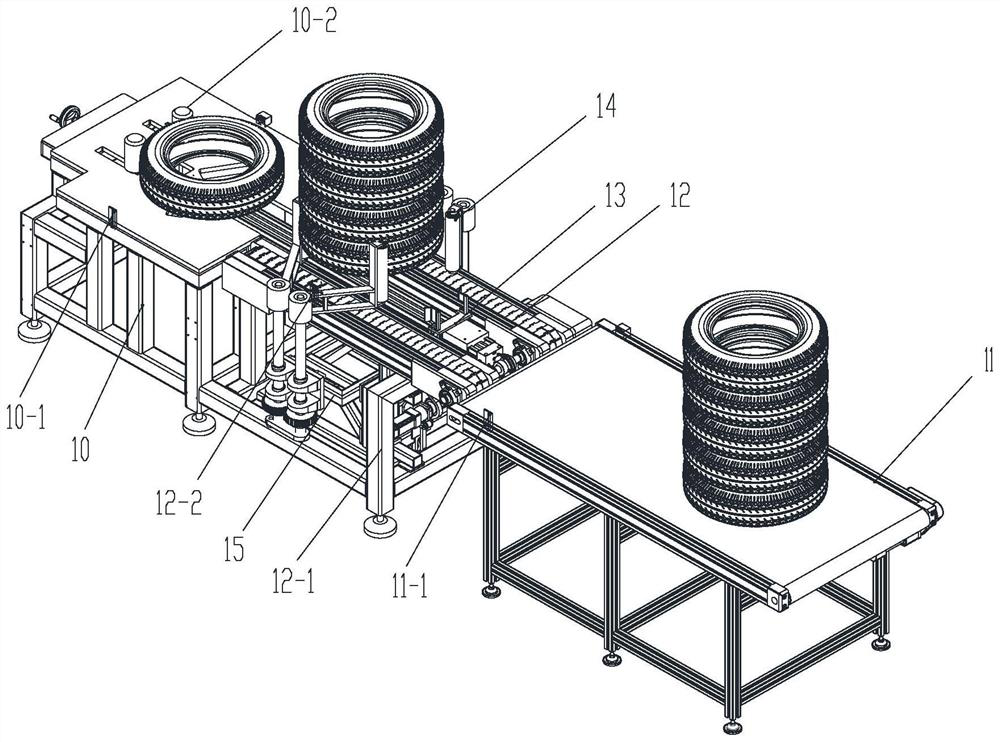

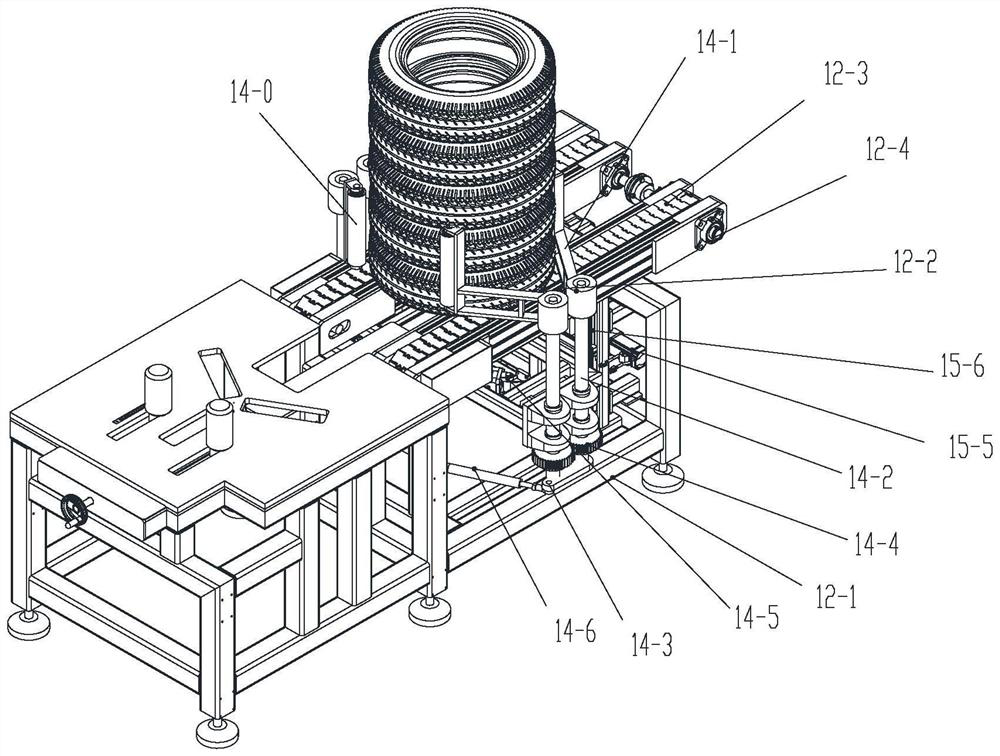

[0037] Example 1, as figure 1 As shown, the motorcycle tire assembly and unstacking conveying device applying the conveying method described in this application includes a first conveying assembly 11 and a second conveying assembly 12 connected in sequence.

[0038] Wherein, the first conveying assembly 11 can be optionally a belt conveyor, and a first photoelectric detection assembly 11-1 is arranged on both sides of the frame end;

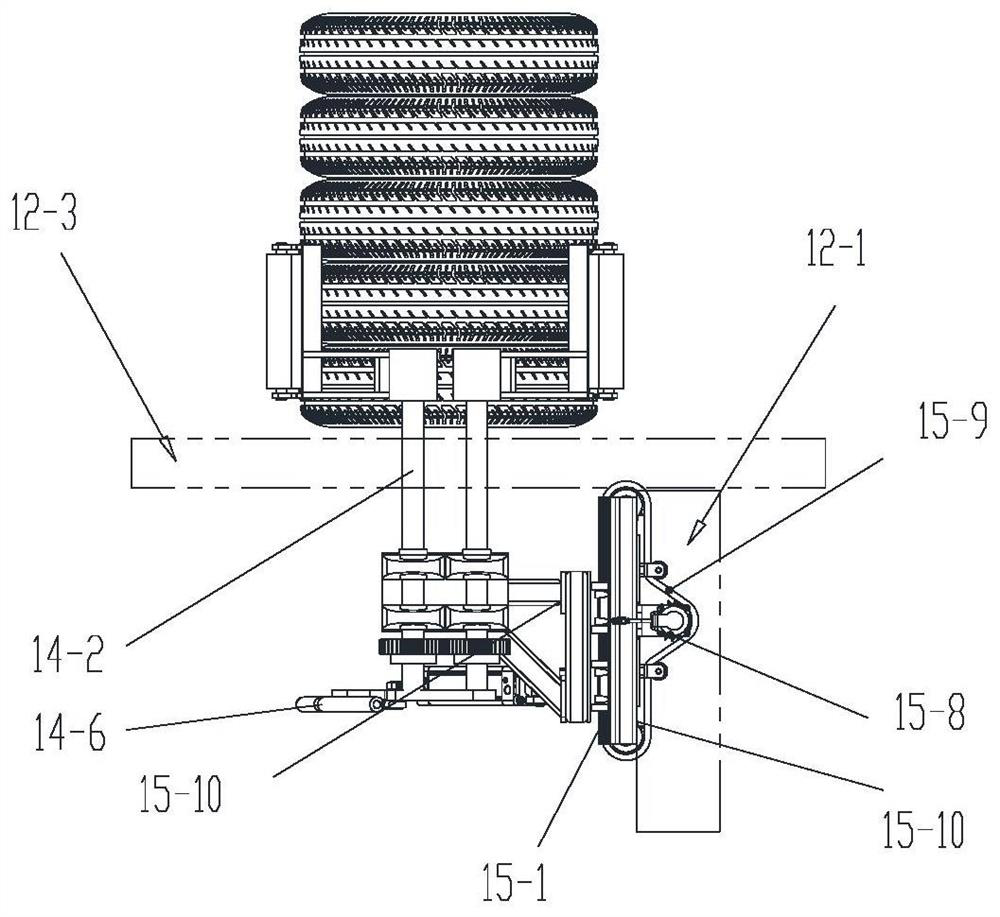

[0039] On the frame 12-1 of the second conveying assembly 12, a tire pushing assembly 13, a clamping assembly 14 and a lifting transmission assembly 15 are installed, and a second photoelectric detection assembly 12-2 is arranged on both sides of the top of the frame 12-1;

[0040] The second conveying assembly 12 extends forward to connect the center frame body 10, and the third photoelectric detection assembly 10-1 is arranged on both sides of the top of the center frame body 10, and is installed on the top of the center frame body 10 for limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com