System and method for improving selectivity of artificial magnetite

An artificial magnet and magnetization roasting technology, applied in the field of metallurgy and mineral processing, can solve the problems of metal loss, inability to recover by weak magnetic separation, etc., and achieve the effect of improving selectivity, small coercive force, and low specific magnetic susceptibility coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

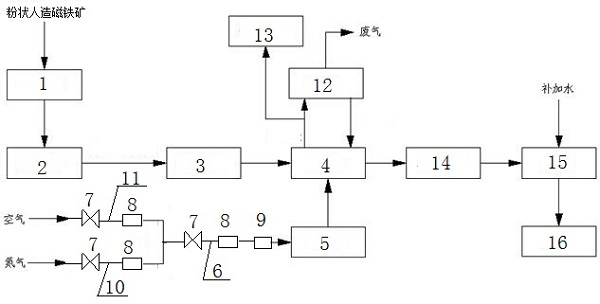

[0023] The system and method of increasing the selectivity of the present invention will be further described below in conjunction with the accompanying drawings.

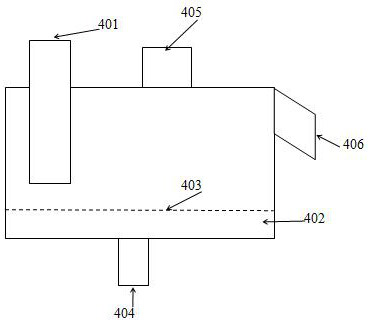

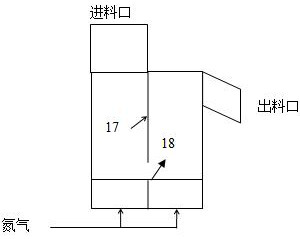

[0024] Such as Figure 1-3 As shown, a system for improving the selectivity of the artificial magnetite, including the magnetized roasted furnace 1, the remaining heat boiler 2, the first material sealing device 3, the re-oxidation reaction chamber 4, the second material sealing device 14, the mixer 5, The dust collector 12, the nitrogen pipeline 10, the compressed air line 11, the wafer groove 15, and the detecting instrumentation 8, 9, 13. The magnetized roasted furnace 1 is connected to the remaining heat boiler 2 feed port, and the remaining heat boiler 2 is connected to the first material sealing device 3 feed port, and the first material sealing device 3 discharge port and the reoxidation reaction chamber 4 The inlet 401 is connected, and the re-oxidation reaction chamber 4 is provided with a winding device 402 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com