High-rising building construction method and device

A construction method and structure technology, applied to building structures, corona discharge devices, buildings, etc., can solve the difficulty of controlling the thickness of the cylinder body, the thickness of the protective layer and the quality of appearance molding, the high requirements for construction joints and verticality control, and the inspection To solve the problems such as the difficulty of people passing through, the construction method is simple and easy, the promotion value is high, and the control is convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

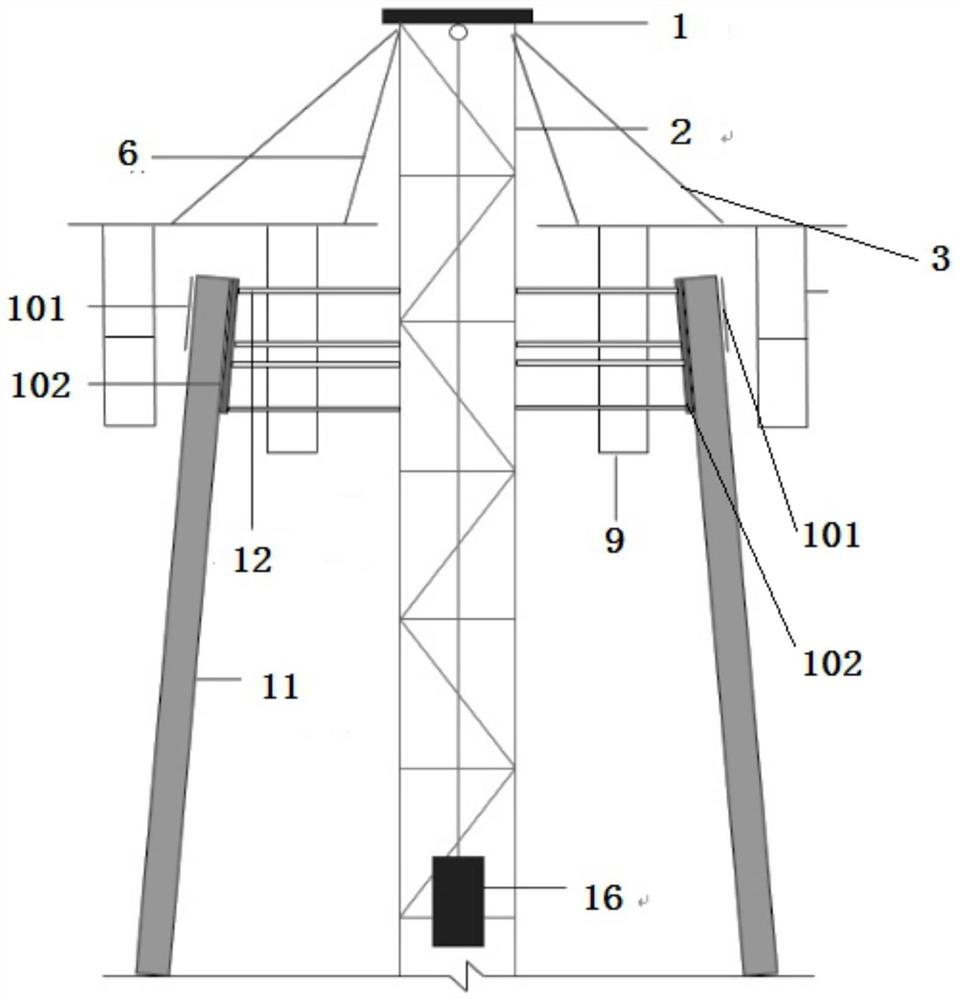

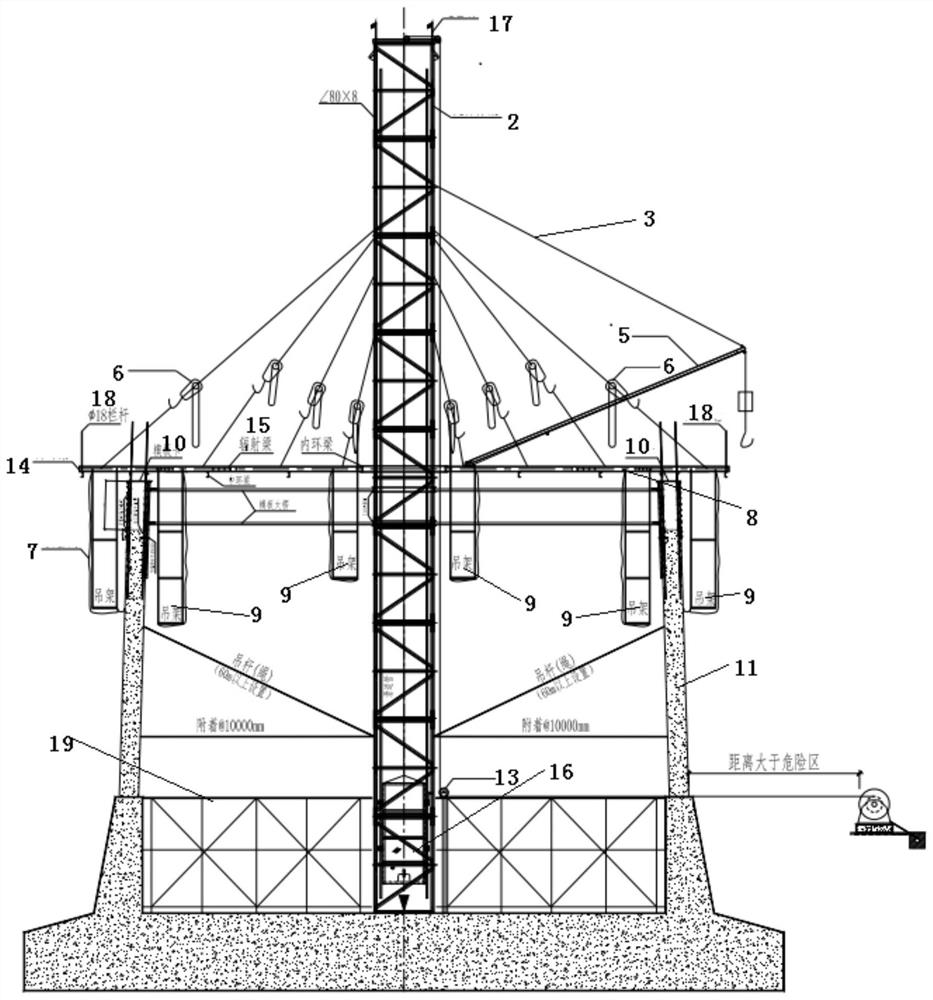

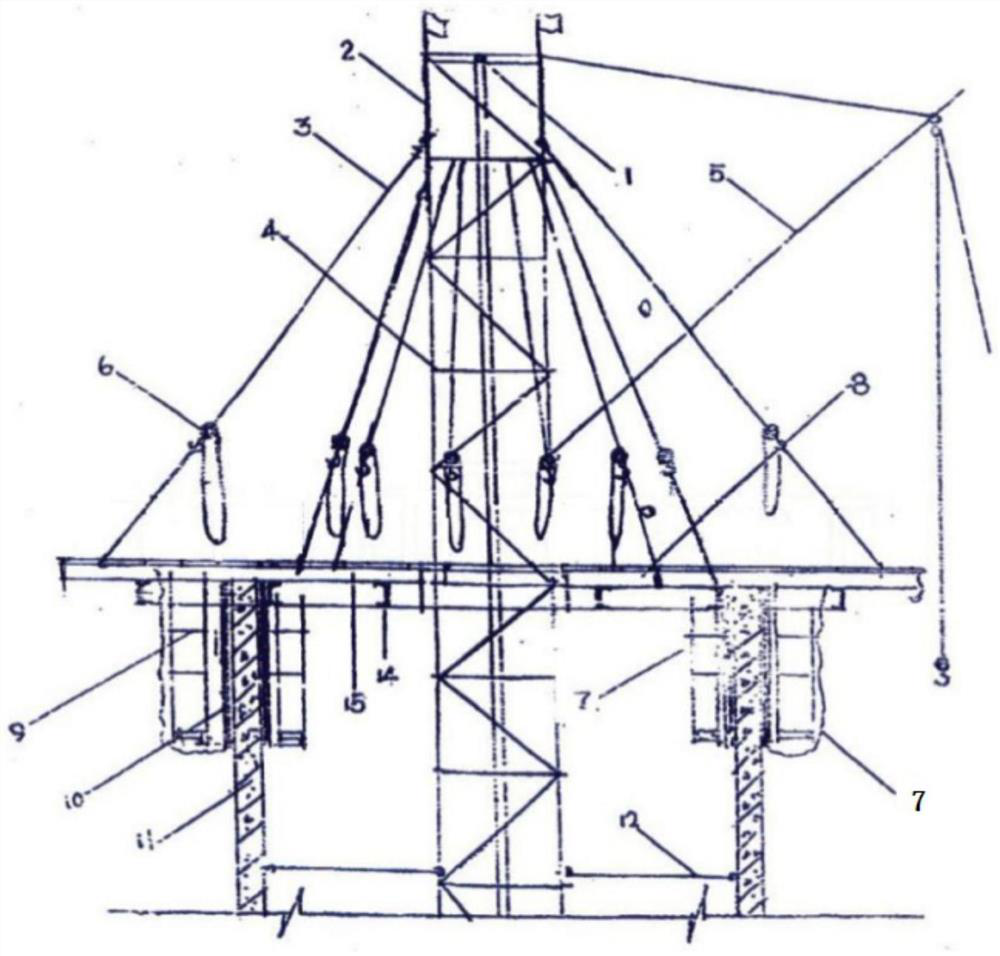

[0079] The present embodiment provides a kind of towering structure construction method, comprises the following steps:

[0080] Step A: Install the shaft frame 2, the operating platform 8 and the vertical transport device on the basis of the structure; the shaft frame 2 is sequentially provided with multiple sets of paired supporting devices along the height direction, and one end of the paired supporting device is connected to the shaft frame 2 fixed connection, the other end is fixed at the corbel of the structure wall 11; the operating platform 8 is radial, with a hook structure, including multiple ring beams and multiple radiation beams connected to the ring beams;

[0081] Step B: install the displaced inner formwork 102 of the construction layer, and carry out the construction of the reinforcement works of the construction layer;

[0082] Step C: install the displaced external formwork 101 of the construction layer, and pour concrete for the construction layer;

[0083...

Embodiment 2

[0243] The present embodiment provides a construction device for a towering structure, including a shaft frame 2 installed on the foundation of the structure, an operating platform 8 installed on the shaft frame 2, a displacement formwork 10, and a vertical transport device; its main structure is as follows:

[0244] (1) Shaft frame 2

[0245] The cross-sectional size of shaft frame 2 is 1.2m*1.2m, the vertical rod of shaft frame 2 is made of angle steel L75*8, the horizontal bar is made of angle steel L50*5, and the inclined rod is made of angle steel L63*6. L100*8 angle steel is used for the reinforcement of the connecting parts of the vertical pole. The length of each single section of the vertical column is 2500mm. Horizontal tie rods are installed at both ends and in the middle. Diagonal tie rods are installed in each section. The first installation height of shaft frame 2 shall not exceed 15m. The vertical bar of shaft frame 2, horizontal bar and inclined stay bar are t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com