Heating and temperature measuring integrated wind speed and wind direction sensor

A wind speed, wind direction, sensor technology, applied in the direction of speed/acceleration/shock measurement, thermometers and instruments with directly sensitive electrical/magnetic components, etc., can solve the problem of limiting the range of thermal wind speed and direction sensors, and achieve fewer chips. The effect of occupying area, expanding range, and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

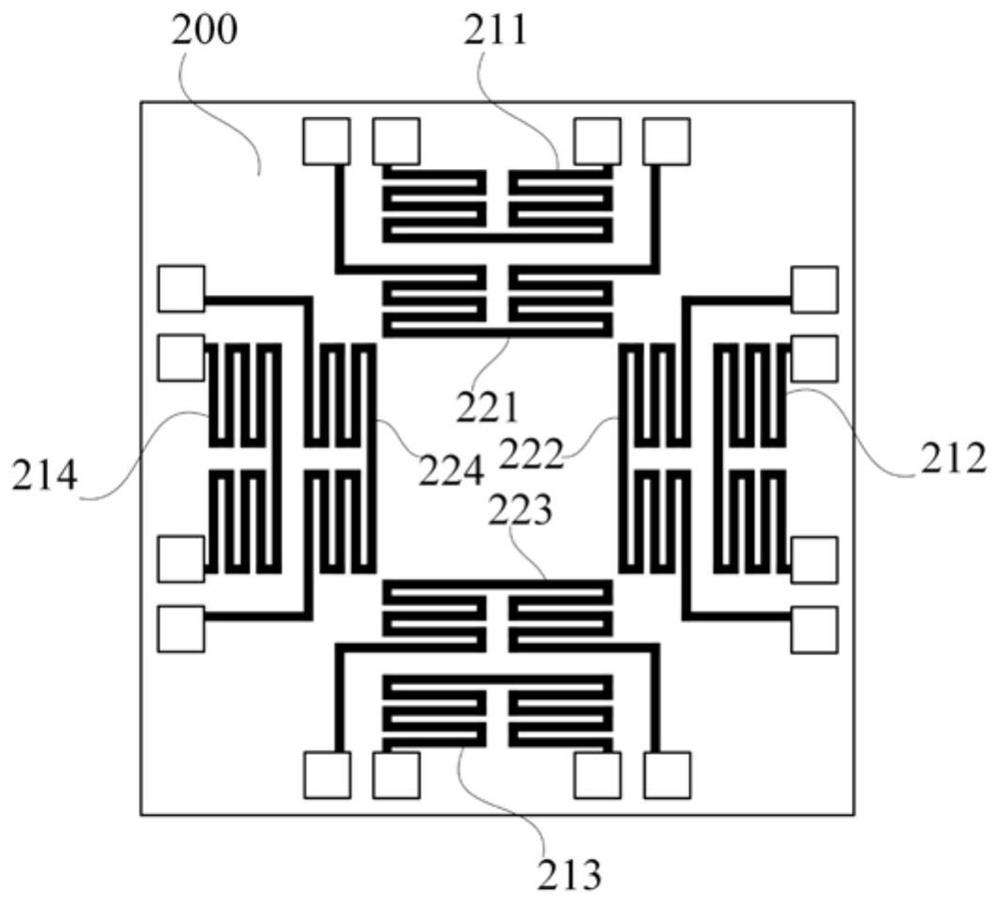

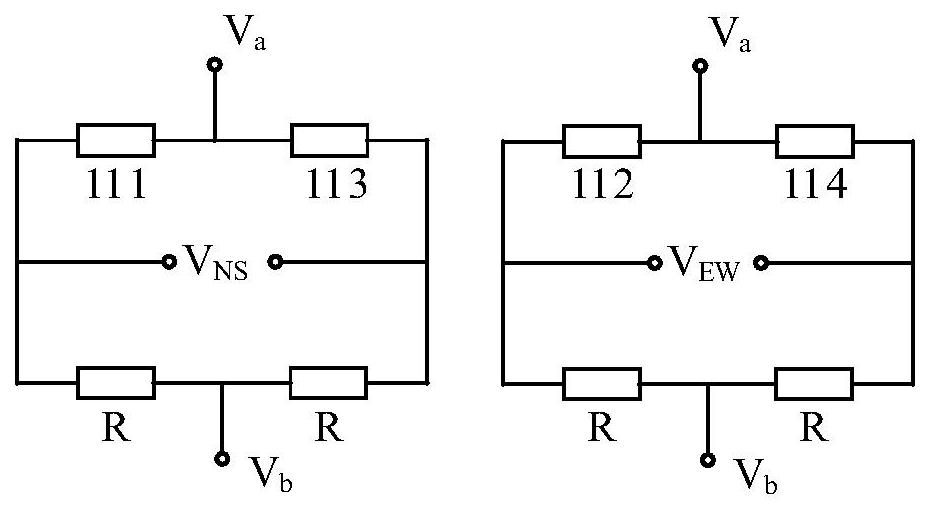

[0016] A wind speed and direction sensor integrated with heating and temperature measurement of the present invention includes a Wheatstone bridge and a constant temperature difference closed-loop control loop for powering the Wheatstone bridge. The Wheatstone bridge includes a first Wheatstone bridge and a second Wheatstone bridge connected in parallel. The first Wheatstone bridge and the second Wheatstone bridge have common voltage input terminals Va and Vb, and the output terminals of the constant temperature difference closed-loop control loop are respectively connected to the voltage input terminals Va and Vb of the Wheatstone bridge. The constant temperature difference closed-loop control loop provides voltage for the Wheatstone bridge, and it increases with the increase of wind speed, thereby improving the sensitivity of the sensor at high wind speed.

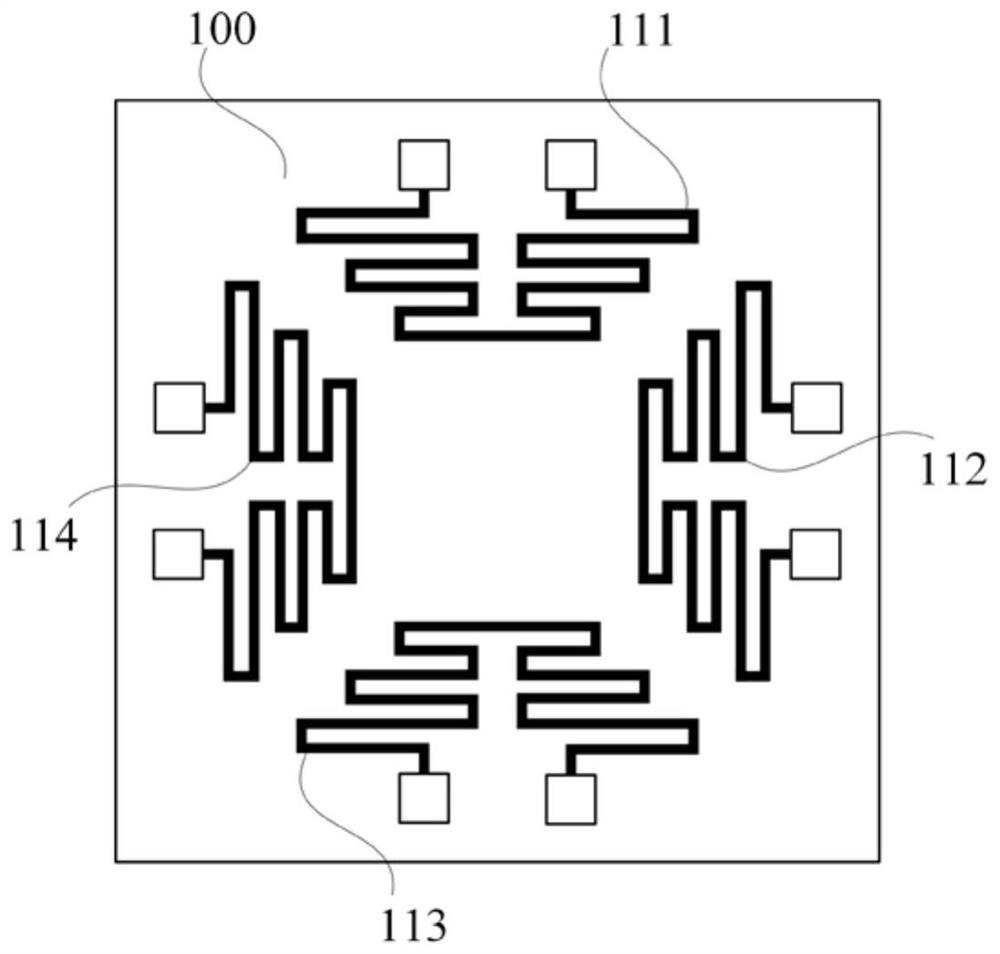

[0017] The Wheatstone bridge includes four thermistors located on the chip substrate 100 and four identical external r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com