Cylindrical rotor structure optimization method and transverse flux linear switched reluctance motor

A switched reluctance motor, transverse magnetic flux technology, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of unstable running unilateral linear motor, large thrust pulsation, etc., to achieve low cost and reduce thrust fluctuations , the effect of improving the performance of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further specifically described below in conjunction with the accompanying drawings and embodiments.

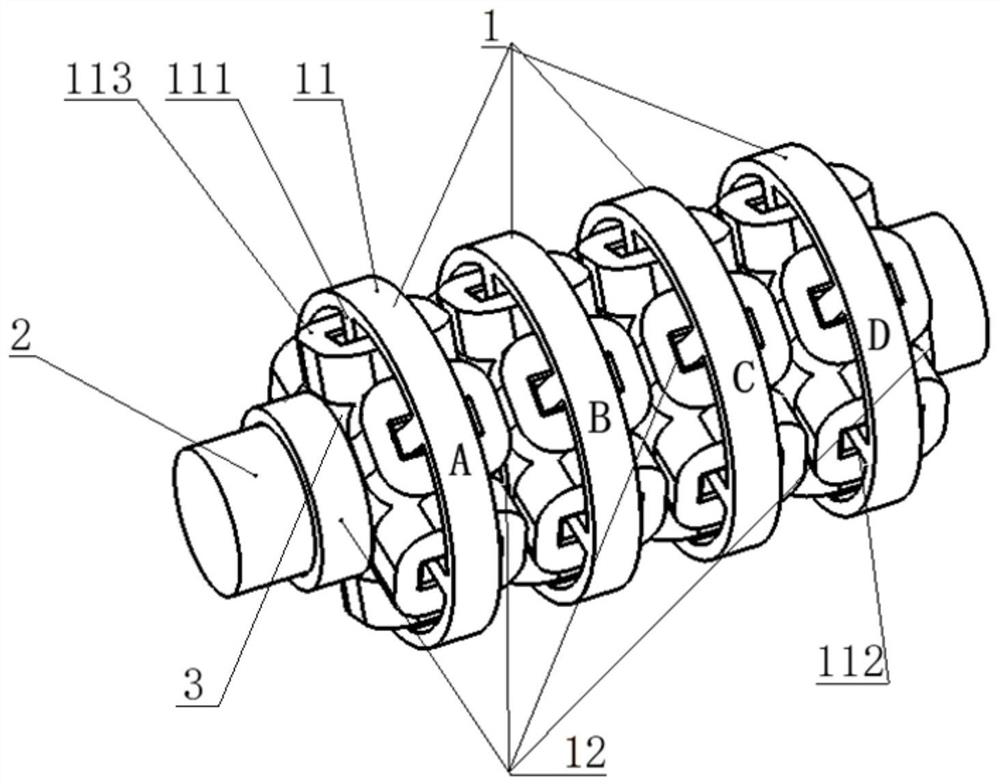

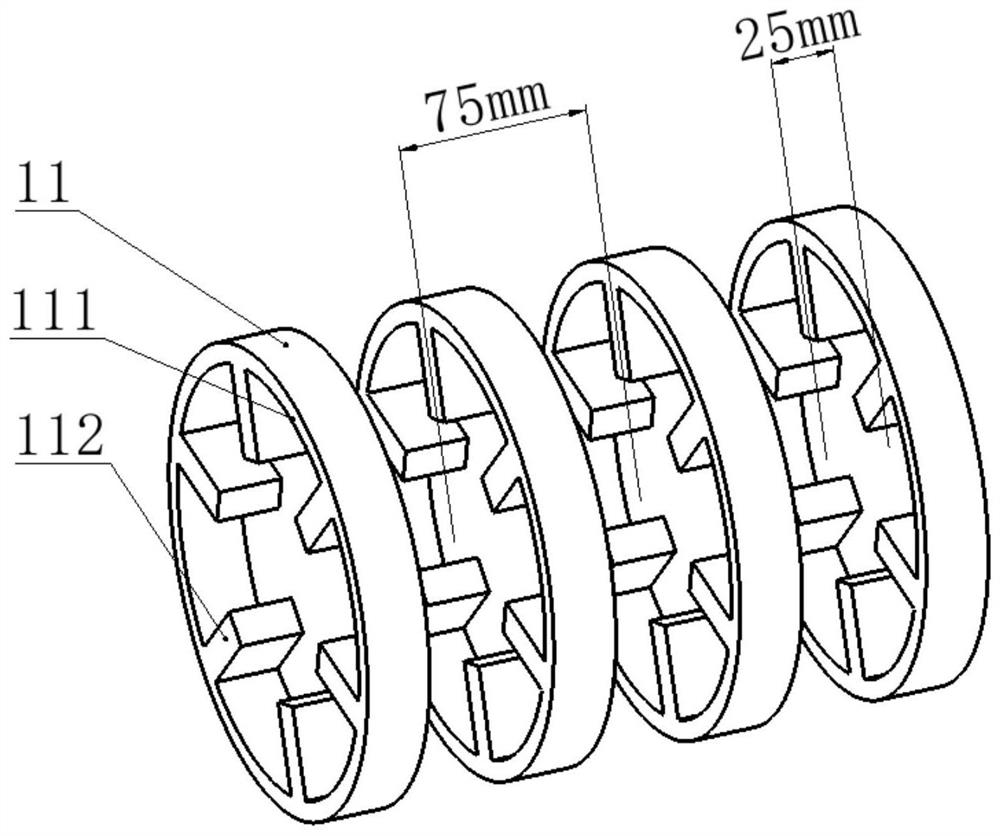

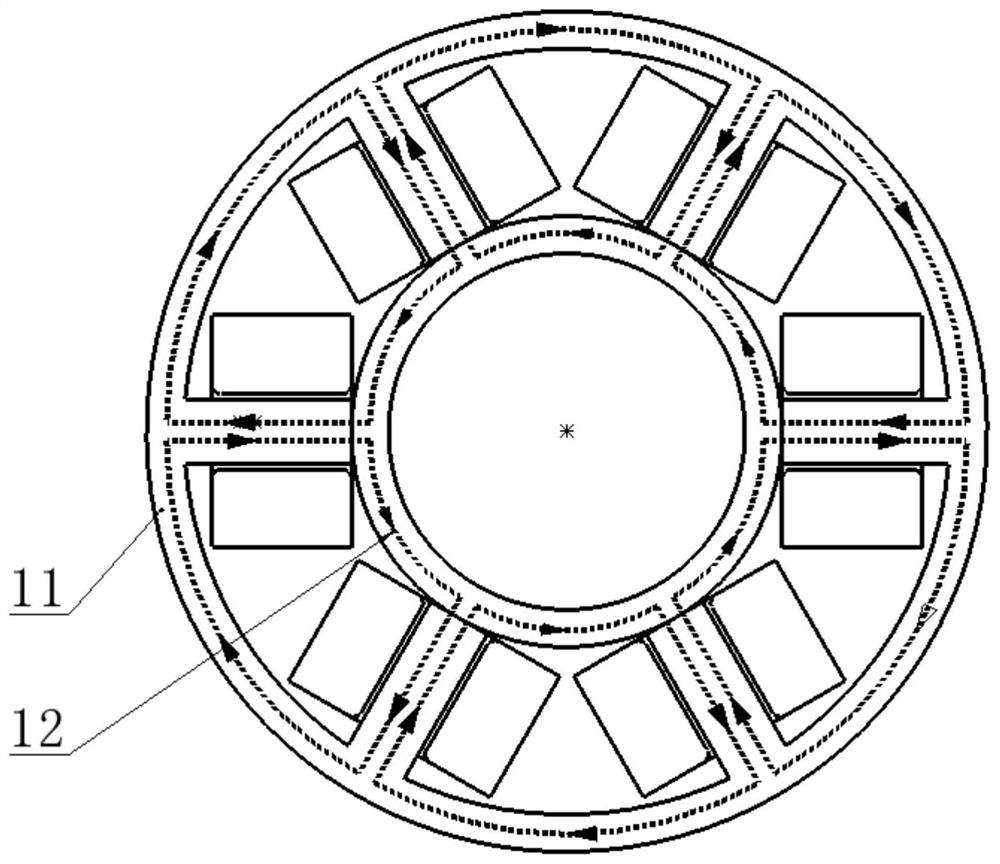

[0046] Such as figure 1 As shown, it is a schematic diagram of the interior of the transverse flux linear switched reluctance motor provided by the present invention. The motor includes a housing (not shown in the figure), and four phase modules 1 arranged at equal intervals along the moving direction are arranged in the housing. And a transmission shaft 2, each phase module 1 is coaxially provided with a cylindrical stator 11 and a mover 12 from the outside to the inside, the axis of the stator 11 and the mover 12 runs through the drive shaft 2, the mover 12 and the stator 11 An air gap 3 is formed therebetween to realize relative linear movement of the stator 11 and the mover 12 along the axial direction.

[0047] In this embodiment, the design of the mover of a four-phase switched reluctance motor is taken as an example, and four phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com