Plant fiber feed raw material treatment device

A technology for feed raw materials and processing devices, applied in animal feed, animal feed, feed and other directions, can solve the problems of debris, becoming impurities, difficult to separate and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

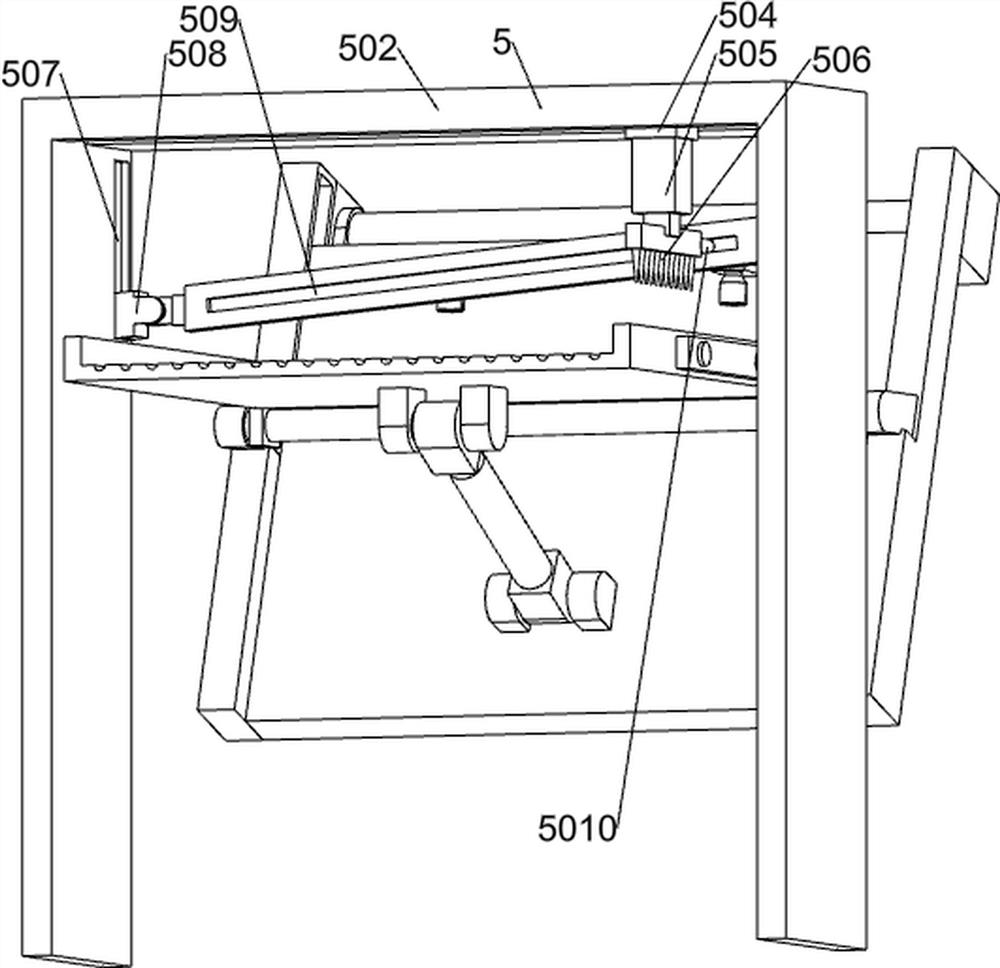

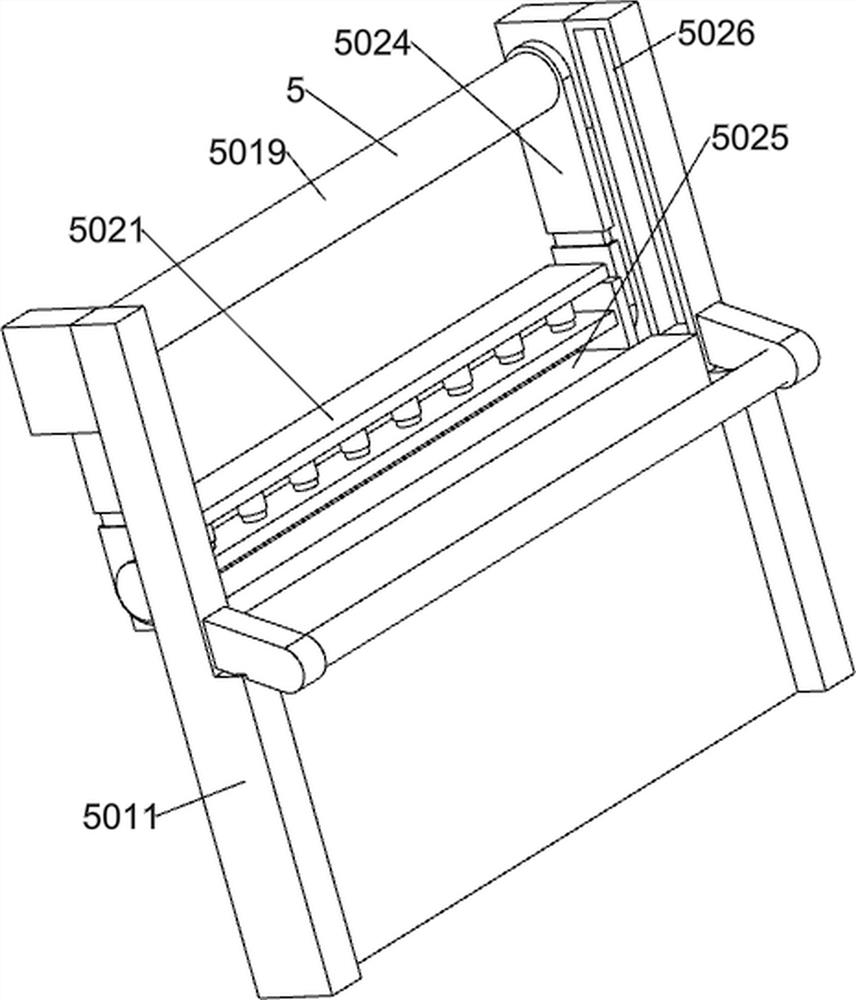

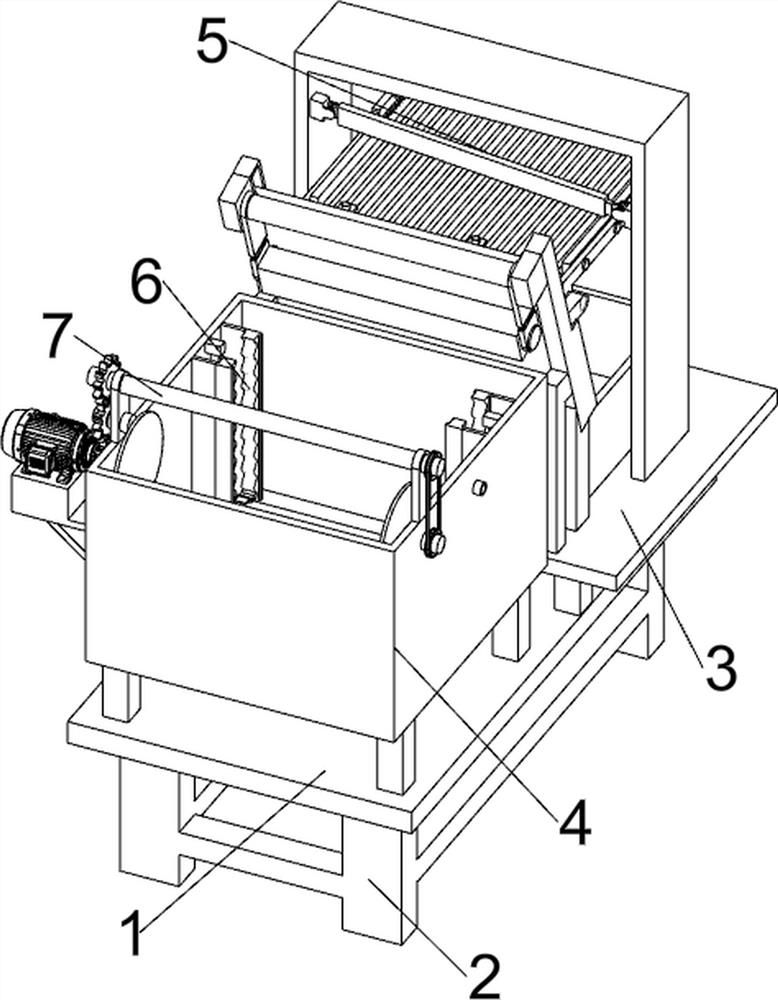

[0030] A plant fiber feed raw material processing device, such as Figure 1-13 As shown, it includes a working machine board 1, a support stand 2, a load-bearing installation plate 3, a soaking cabin 4, a pod removal system 5, a shearing system 6 and a wave processing system 7; Welding; the upper part of the working machine plate 1 is welded with the load-bearing installation plate 3; the upper part of the working machine plate 1 is connected with the immersion cabin 4 by bolts; the upper part of the load-bearing installation plate 3 is connected with the pod removal system 5 by bolts; the shearing system 6 is connected with the immersion cabin 4 The wave processing system 7 is connected with the soaking cabin 4; the wave processing system 7 is connected with the shearing system 6.

[0031] When using the plant fiber feed raw material processing device, firstly fix the device stably on the working plane, then connect the power supply and the controller externally, and then add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com