High-efficiency coating machine with high-applicability stirrer

A stirrer and applicability technology, applied in the field of high-efficiency coating machines, can solve the problems of reducing yield, wasting hot air energy, affecting tablet core quality, etc., and achieve the effect of reducing cracking and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

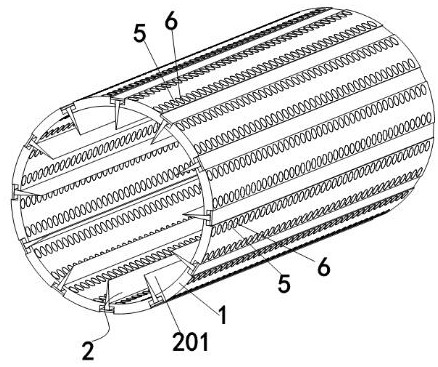

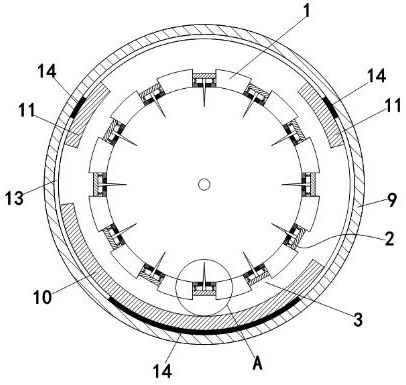

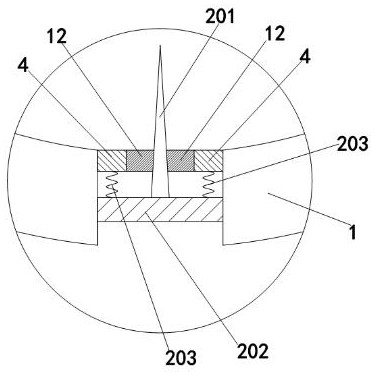

[0028] Such as Figure 1 to Figure 6 As shown, the present invention provides a high-efficiency coating machine with a high applicability agitator, comprising a pot body 1, on which a plurality of sets of adjustment devices 2 are arranged, and the adjustment device 2 includes an agitator 201, and the external drive assembly When the pot body 1 is driven to rotate, the pot body 1 drives the agitator 201 and the tablet core to be coated to rotate, and at the same time, after the agitator 201 drives the tablet core to rise to a certain height, the tablet core slides from the agitator 201, and then stirs. The device 201 makes the chip core produce the effect of lifting. During the process of the chip core from lifting to sliding, the chip core continuously, continuously and repeatedly makes complex trajectory movements, and gaps are generated between the chip cores. On the one hand, it is beneficial to pass The spray gun sprays the coating medium on the tablet core, so that the me...

Embodiment 2

[0048] After working for a long time, generally there are more coating medium, tablet core powder, etc. adhered to the mixer 201, which are difficult to remove; and when different types of tablet cores need to be coated with different media, the pot needs Body 1 is thoroughly cleaned, because the blocking factor of agitator 201 causes the inside of pot body 1 and agitator 201 self-cleaning inconvenience.

[0049] At this time, by adjusting the magnetic force of the first electromagnet 10 or the second electromagnet 11, it produces a larger magnetic force on the sliding block 202. On the one hand, when the sliding block 202 drives the agitator 201 to move up and down, the elastic sealing block 12 can Effectively scrape off the coating medium and tablet core powder adhering to the surface of the agitator 201 to facilitate cleaning of the agitator 201; on the other hand, the slider 202 drives the agitator 201 above it to move down to the lowest position , the upper part of the ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com