Monoatom and particle synergistic supported metal catalyst as well as preparation method and application thereof

A metal catalyst, metal technology, applied in catalyst activation/preparation, molecular sieve catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of poor selectivity, low activity, harsh reaction conditions, etc. The effect of presentability, high catalytic activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the metal catalyst provided by the invention comprises the following steps: (1) immersing the carrier in a solution composed of a metal salt and a solvent, removing the solvent after the immersion to obtain a metal catalyst precursor; (2) heating the metal catalyst precursor Then, a supported metal catalyst with synergy between single atoms and particles can be obtained. The invention utilizes a simple impregnation method and a high-temperature pyrolysis method to prepare a single-atom-particle synergistic supported metal catalyst, and the metal precursor is loaded on the surface of the carrier by the impregnation method. Due to the high specific surface area of the carrier, during the high-temperature pyrolysis process, the metal The salt precursor is decomposed and anchored inside the pores of the support in the form of single atoms and particles coexisting, thus obtaining a metal catalyst with support-supported single atoms and particles. ...

Embodiment 1

[0046] Example 1. Preparation and application of mesoporous carbon-supported single atom and particle synergistic iridium metal catalyst

[0047] The mesoporous carbon-supported single-atom-particle synergistic iridium metal catalyst was prepared according to the following steps:

[0048] (1) Weigh 5 mg of iridium acetylacetonate into a 25 mL single-necked bottle, add 5 mL of acetone, and stir for 15 minutes. Weigh 100mg of CMK-3 and add it into the above solution, stir at 400r / min for 6 hours, and then spin evaporate at 30°C and 100rpm for 15 minutes.

[0049] (2) Place the solid powder obtained after the rotary steaming in step (1) in a porcelain boat, and perform pyrolysis in a tube furnace. In an argon atmosphere, the temperature was raised to 600°C at a heating rate of 5°C / min and kept for 2h, and then naturally cooled to room temperature to obtain a mesoporous carbon-supported single-atom and particle-coordinated iridium metal catalyst Ir- CMK-3.

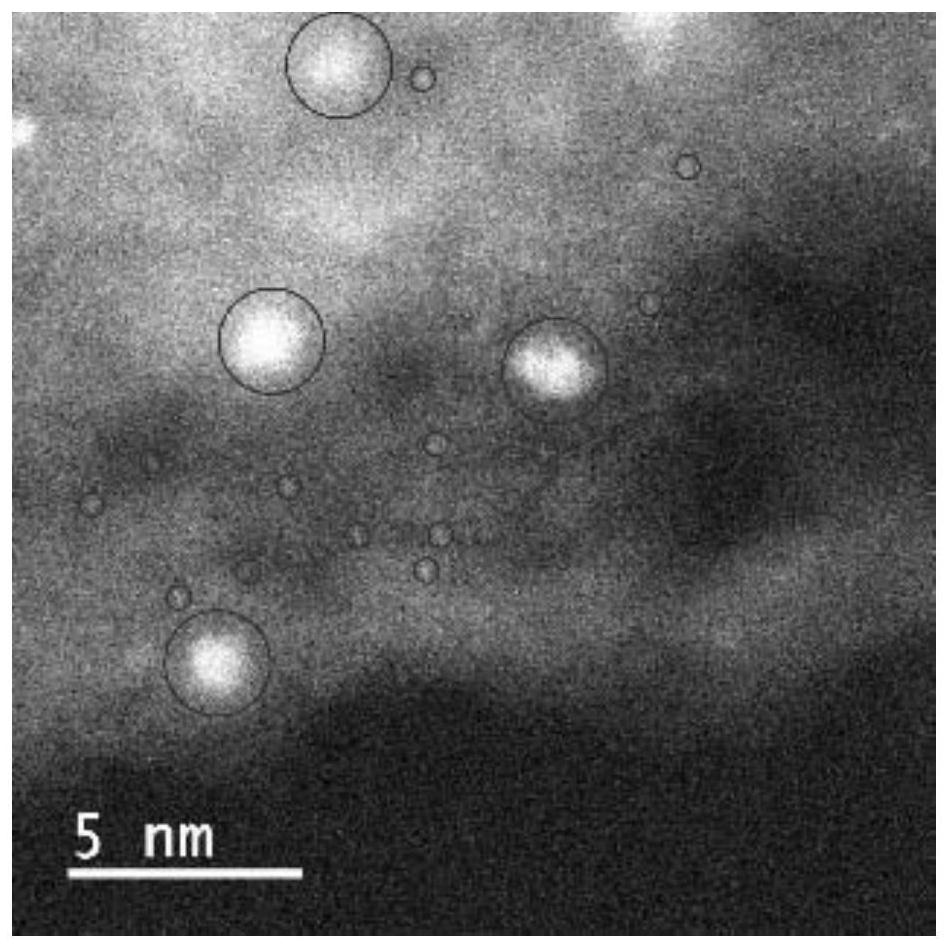

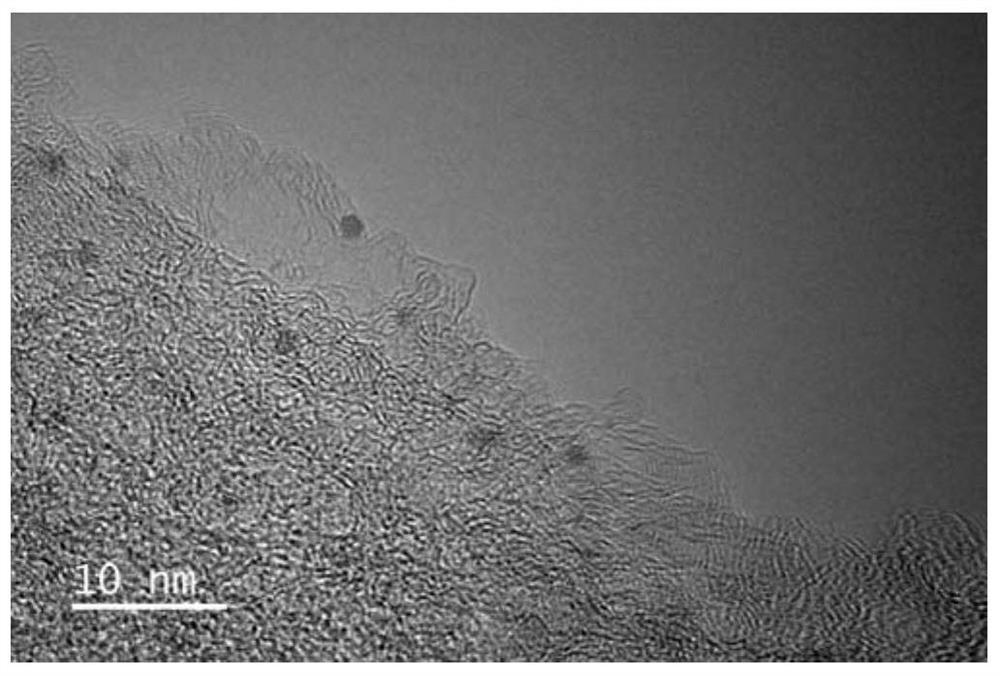

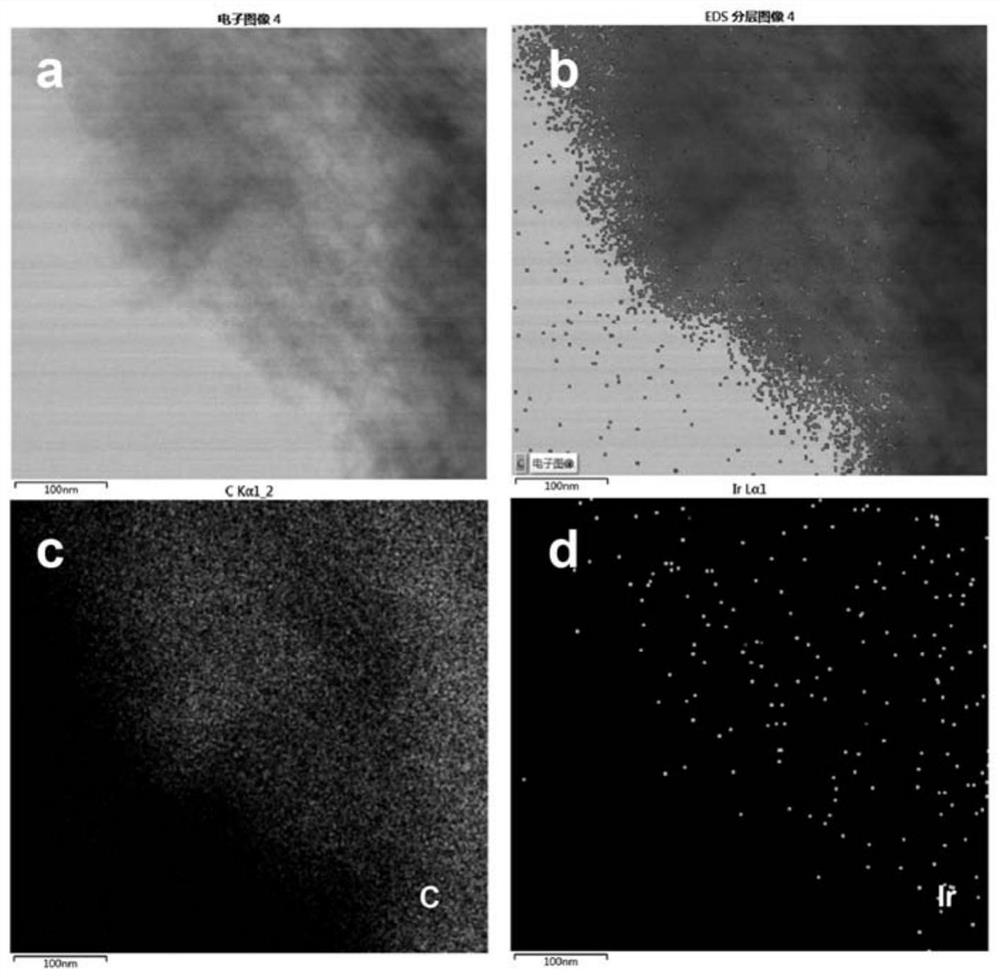

[0050] The spherica...

Embodiment 2

[0057] Example 2, Preparation and Application of Activated Carbon-supported Single Atom and Particle Synergistic Ruthenium Metal Catalyst

[0058] Activated carbon-supported single atom and particle synergistic ruthenium metal catalysts were prepared according to the following steps

[0059] (1) Weigh 10 mg of ruthenium acetylacetonate into a 25 mL single-necked bottle, add 5 mL of acetone, and stir for 15 minutes. Weighed 100mg of activated carbon (Vulcan XC-72R Active carbon purchased from Cabot Company) was added to the aforementioned solution, stirred at 400r / min for 6 hours, and then rotary evaporated at 30°C and 100rpm for 15 minutes.

[0060] (2) The solid powder obtained by rotary steaming in step (1) is placed in a porcelain boat, and pyrolyzed in a tube furnace. In an argon atmosphere, the temperature was raised to 500 °C at a heating rate of 5 °C / min and kept for 2 h, and then naturally cooled to room temperature to obtain a ruthenium metal catalyst Ru-C supported ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap