20Cr13 upsetting heating device and upsetting heating process

A 20cr13, 1.20cr13 technology, applied in the field of 20Cr13 upsetting heating device and upsetting heating process, can solve the problems of inability to quickly adjust, hidden dangers of ingot safety, low forging temperature, etc., to reduce hidden dangers, improve the scope of application, avoid The effect of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

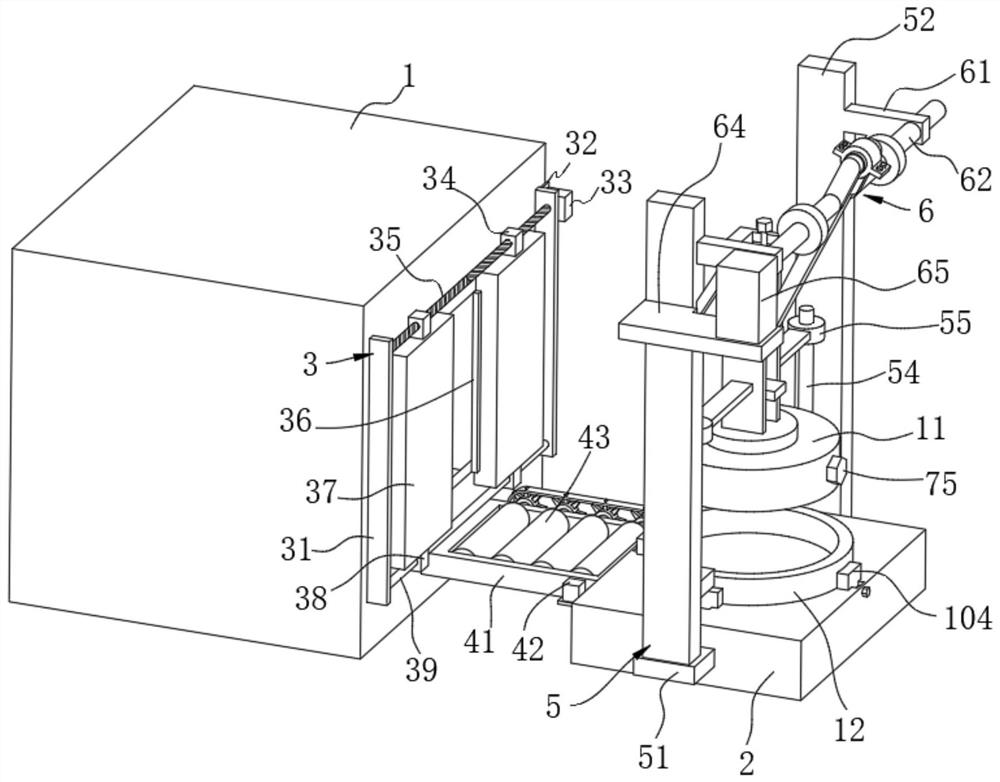

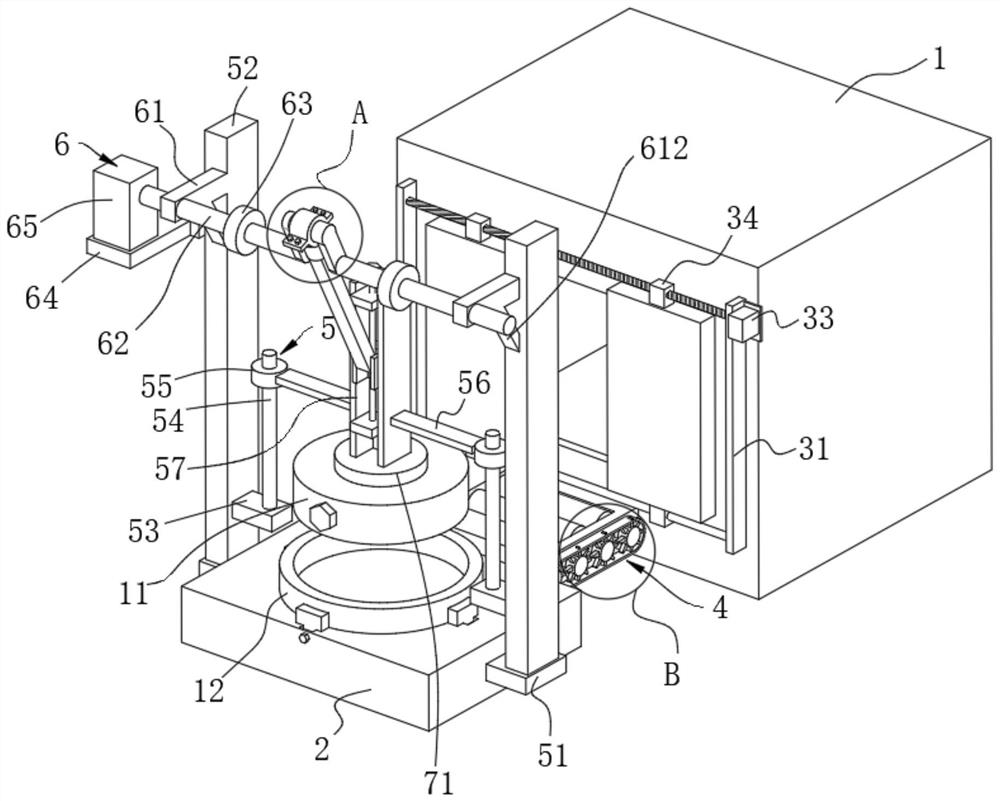

[0049] Example 1, please refer to Figure 1-9 , this embodiment provides a technical solution: 20Cr13 upsetting heating device, including:

[0050] A heat treatment furnace 1, the side opening of which is equipped with a furnace door unit 3;

[0051] The heat transfer unit 4 is installed on one side of the heat treatment furnace 1 and is arranged corresponding to the opening on the side of the heat treatment furnace 1;

[0052] Upsetting seat 2, which is installed on the end of the heat transfer unit 4 away from the heat treatment furnace 1, and the interior of the upsetting seat 2 is equipped with a heat preservation unit 9;

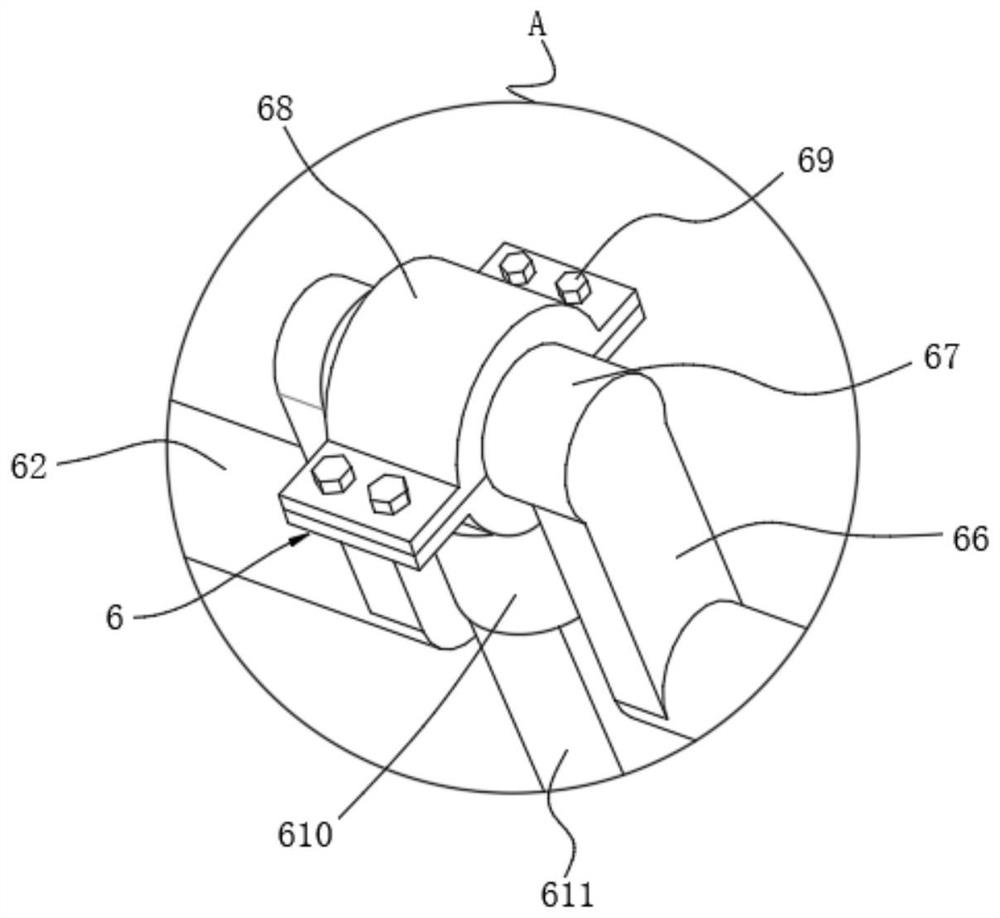

[0053] The upsetting limit installation unit 5 is installed on the upsetting seat 2, the upsetting limit installation unit 5 is connected to the height adjustment unit 8 through the upsetting power unit 6, and the upsetting limit installation unit 5 is also connected through the disassembly unit 7 Upsetting round block 11 is installed;

[0054] The u...

Embodiment 2

[0079] Example 2, please refer to figure 1 , this embodiment provides a technical solution: 20Cr13 upsetting heating device. Hole block 34, two-way lead screw 35, heat shield 36, switch door 37, slide hole block 38 and slide bar 39, the side opening both sides of heat treatment furnace 1 are respectively provided with side bar 31, between the top of two side bars 31 There is a two-way lead screw 35 that is rotationally connected, and the two ends of the two-way lead screw 35 have opposite thread directions, and a slide bar 39 is fixedly connected between the bottoms of the two side bars 31, and two switch doors 37 are provided with two switch doors 37. The top of each is provided with screw hole block 34, and two screw hole blocks 34 are threadedly connected with the two ends of two-way lead screw 35, and the bottom of two switch doors 37 is respectively provided with slide hole block 38, and two slide hole blocks 38 are connected with slide hole block. The rod 39 is slidingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com