Aluminum foil veneer on-line rectangular grid printing equipment and use method thereof

An aluminum foil veneer and equipment technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as poor applicability, improve applicability, improve convenience, and simplify the process of material addition. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

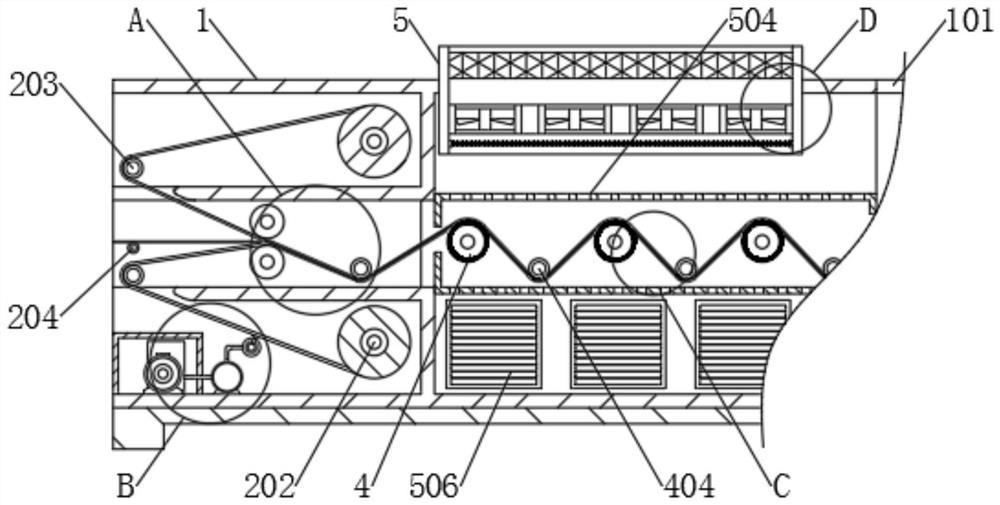

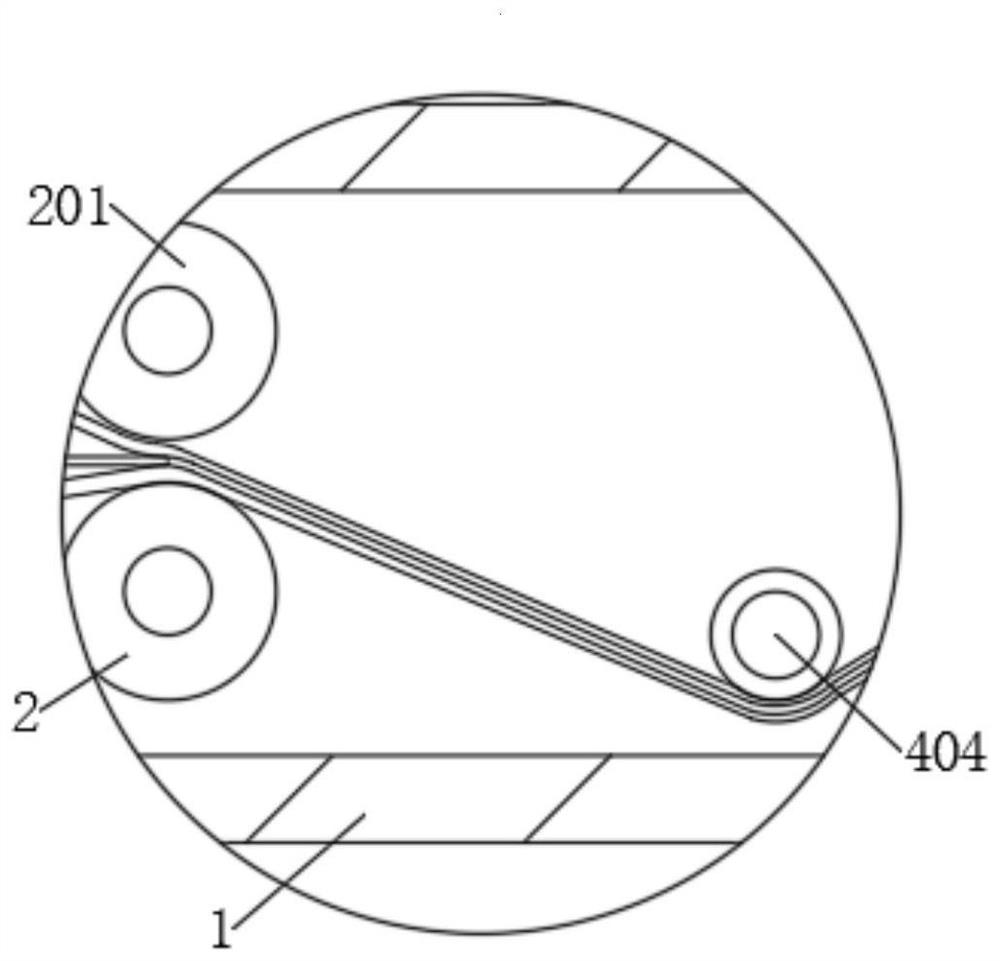

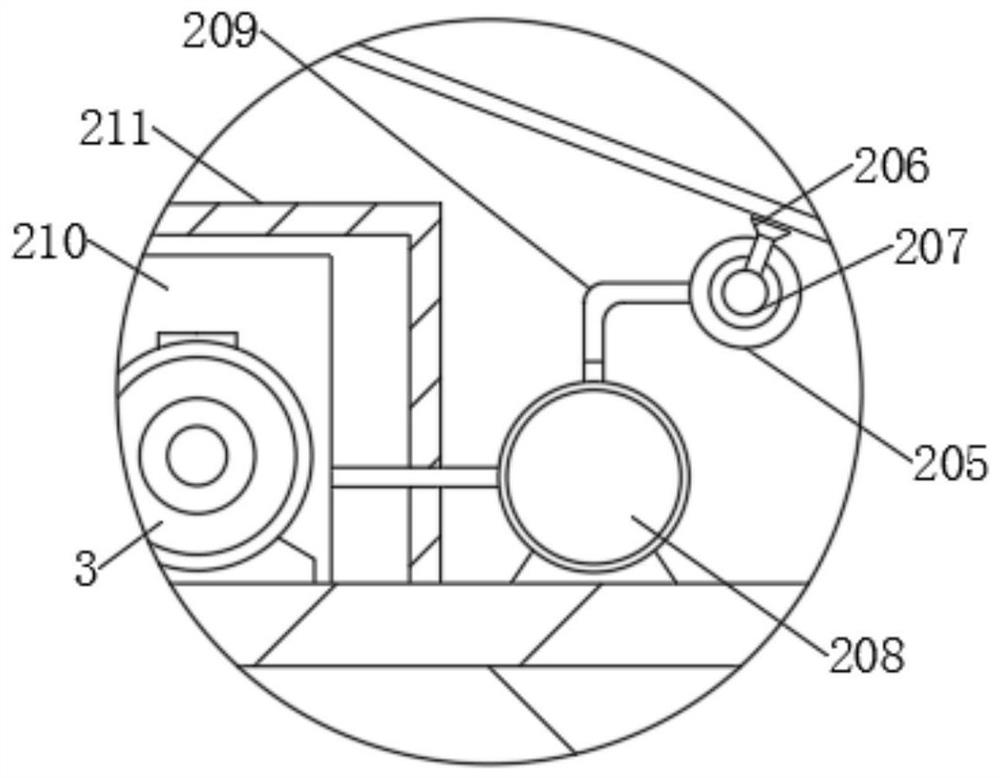

[0047] The invention discloses a device for making rectangular grids on-line with aluminum foil veneers. Figure 1-Figure 10 As shown, it includes a device body 1, a composite pressing roller 2, a drive motor 3, a drying support roller 4, and an auxiliary drying rack 5.

[0048] ginseng Figure 6 As shown, a cutting mechanism 101 is connected to one side of the device body 1 , so that the composite pressed aluminum foil veneer can be cut by the cutting mechanism 101 .

[0049] ginseng Figure 1-Figure 2 As shown, the composite pressing roller 2 is arranged in the equipment body 1, and one side of the composite pressi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com