An artificial skin that simulates perspiration

An artificial skin and polyurethane technology, applied in the field of medical education, can solve the problems of abnormal perspiration, non-appearance, and inability to simulate students, and achieve the effect of accurate temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

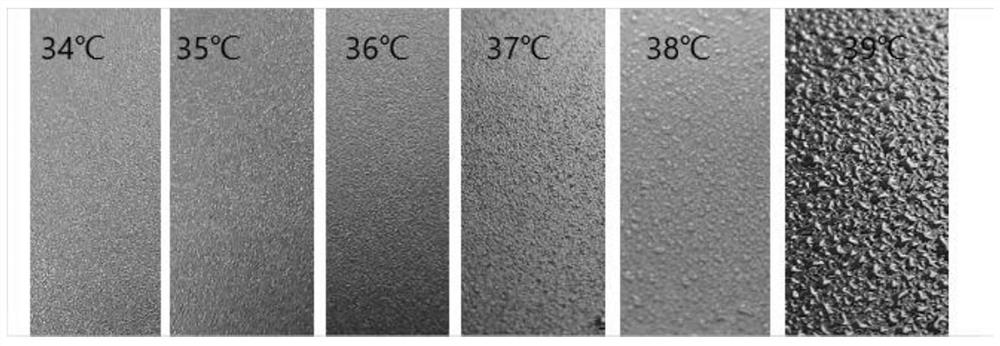

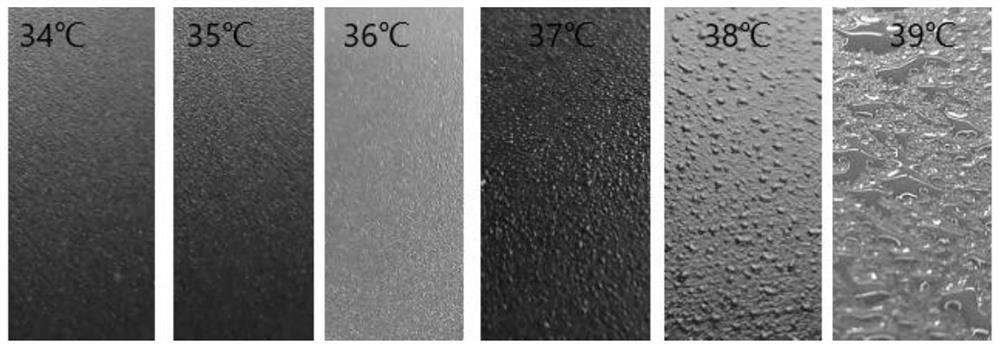

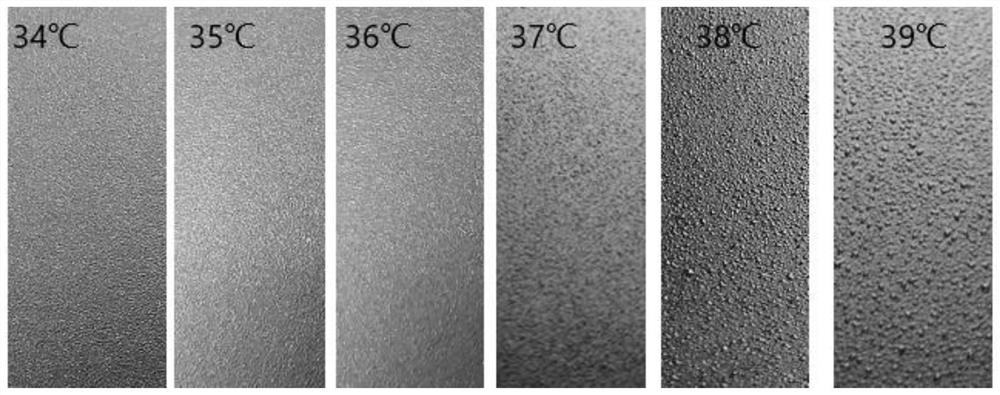

Image

Examples

Embodiment 1

[0058] (1) The preparation steps of the temperature-sensitive polyurethane hydrogel layer are as follows:

[0059] Step (1) Weigh 10 parts of carbon nanotubes, 10 parts of polyether polyol, 3 parts of isocyanate, 2 parts of MOCA, 2 parts of N-ethylmorpholine, 2 parts of tantalum pentoxide, 3 parts of pentaerythritol, 3 parts of stannous octoate and 2 parts of EDTA disodium magnesium salt;

[0060] Step (2) Pour the weighed carbon nanotubes and water in step (1) into an emulsifying machine, the speed of the emulsifying machine is set to 1000r / min, the emulsifying time is 5min, and the emulsifying treatment is performed to obtain the carbon nanotubes turbidity liquid;

[0061] Step (3) introducing ozone gas into the carbon nanotube emulsion obtained in step (2), and the ozone concentration of the carbon nanotube emulsion is 200 mg / m 3 , the reaction time is 30min, the hydrophilic carbon nanotubes are obtained, extracted and dried to obtain modified carbon nanotubes;

[0062] ...

Embodiment 2

[0077] (1) The preparation steps of the temperature-sensitive polyurethane hydrogel layer are as follows:

[0078] Step (1) Weigh out 20 parts by weight of carbon nanotubes, 20 parts of polyether polyol, 5 parts of isocyanate, 5 parts of MOCA, 5 parts of N-ethylmorpholine, 5 parts of tantalum pentoxide, 8 parts of pentaerythritol, 5 parts of stannous octoate and 5 parts of EDTA disodium magnesium salt;

[0079] Step (2) Pour the weighed carbon nanotubes and water in step (1) into an emulsifier, the speed of the emulsifier is set to 2000r / min, the emulsification time is 40min, and the emulsification treatment is performed to obtain the carbon nanotubes turbidity liquid;

[0080] Step (3) introducing ozone gas into the carbon nanotube emulsion obtained in step (2), and the ozone concentration of the carbon nanotube emulsion is 500 mg / m 3 , the reaction time is 5h, the hydrophilic carbon nanotubes are obtained, extracted and dried to obtain modified carbon nanotubes;

[0081] ...

Embodiment 3

[0096] (1) The preparation steps of the temperature-sensitive polyurethane hydrogel layer are as follows:

[0097] Step (1) Weigh out 15 parts by weight of carbon nanotubes, 15 parts of polyether polyol, 4 parts of isocyanate, 4 parts of MOCA, 4 parts of N-ethylmorpholine, 4 parts of tantalum pentoxide, 6 parts of pentaerythritol, 4 parts of stannous octoate and 4 parts of EDTA disodium magnesium salt;

[0098] Step (2) Pour the carbon nanotubes and water weighed in step (1) into an emulsifier, set the rotational speed of the emulsifier to 1500r / min, and set the emulsification time to 20min, and carry out emulsification treatment to obtain carbon nanotubes with turbidity. liquid;

[0099] Step (3) inject ozone gas into the carbon nanotube emulsion obtained in step (2), and the ozone concentration of the carbon nanotube emulsion is 300 mg / m3 , the reaction time is 2h, the hydrophilic carbon nanotubes are obtained, and the modified carbon nanotubes are obtained by extraction an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com