Papermaking, drying and cracking-preventing equipment for sanitary napkin pulp sheets

A towel pulp sheet and anti-cracking technology, which is applied in the direction of papermaking, paper machine, dryer, etc., can solve the problems of affecting the drying effect, contact, internal material failure, etc., and achieve the effect of active drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

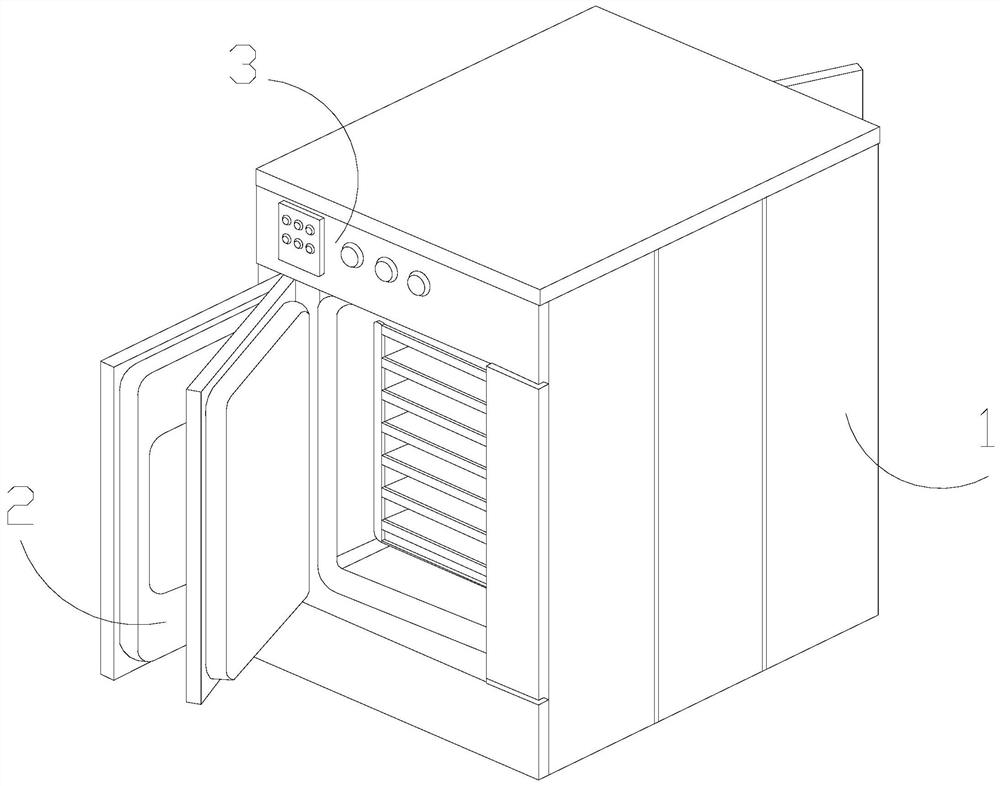

[0031] as attached figure 1 to attach Image 6 Shown:

[0032] The invention provides a sanitary napkin pulp sheet drying and anti-cracking equipment, the structure of which is provided with a box body 1, a door 2, and a control panel 3, the door 2 is hingedly connected to the front and rear ends of the box body 1, and the control panel The panel 3 is integrated with the box body 1 and is located above the front outer side thereof.

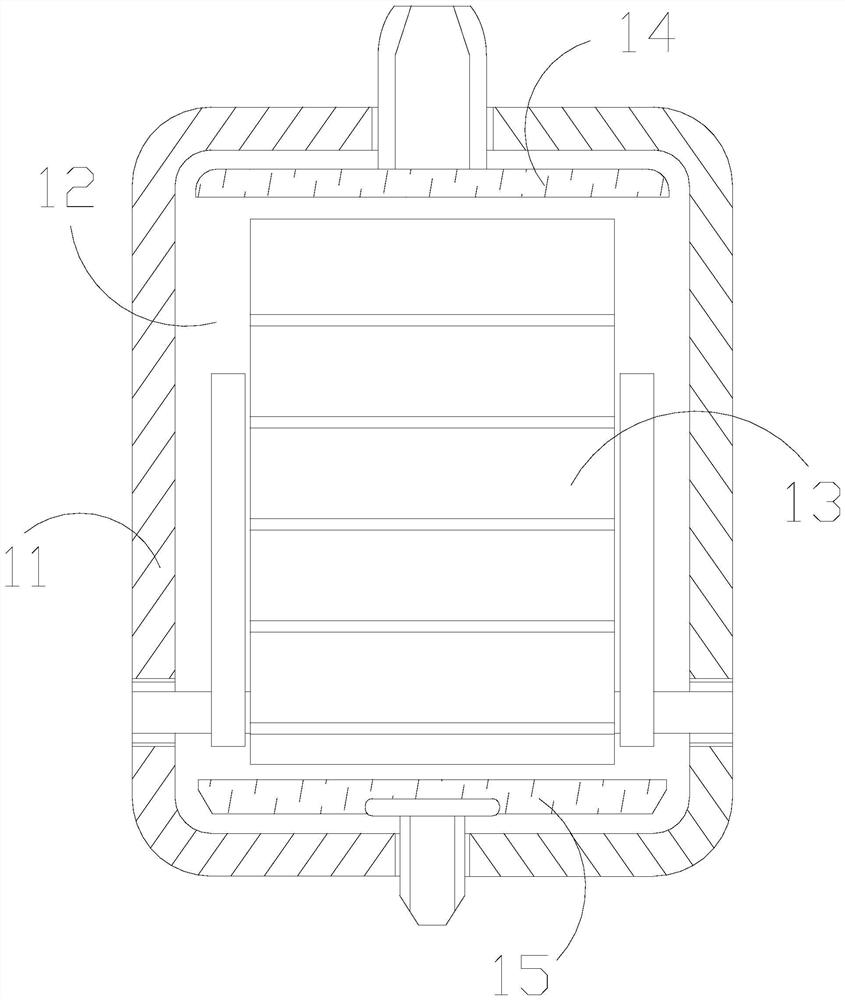

[0033] The box body 1 is provided with an outer frame 11, a drying chamber 12, a carrier frame 13, a heating cover 14, and a heat conduction plate 15. The drying chamber 12 is located inside the outer frame 11, and the heating cover 14 penetrates the outer frame. 11, the heat conducting plate 15 is located at the bottom of the carrier 13, and the carrier 13 is installed in the drying chamber 12.

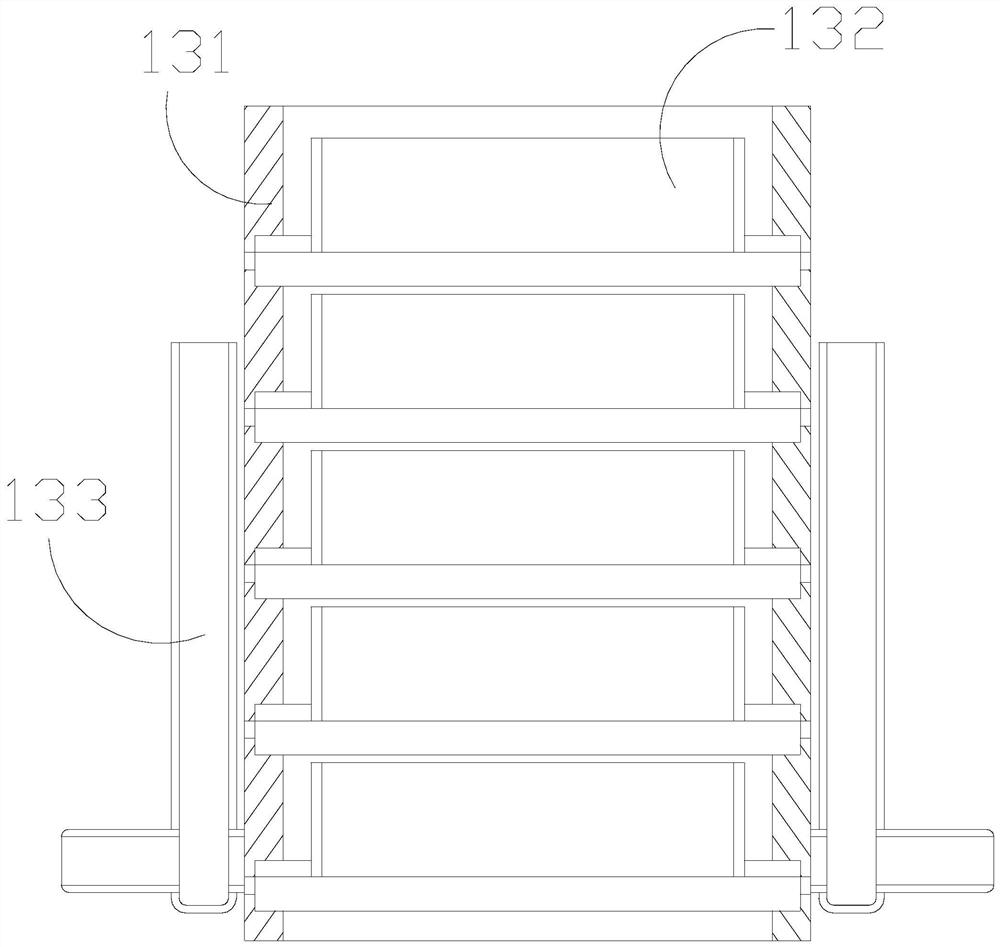

[0034] Wherein, the carrier frame 13 is provided with a supporting frame 131, a supporting device 132, and an exhaust pipe 133. The exhaust pipe 133 ...

Embodiment 2

[0040] as attached Figure 7 To attach Figure 9 Shown:

[0041] Wherein, the tilting plate a24 is provided with a through plate c1, a petal block c2, and a heat absorbing block c3, the petal block c2 is connected outside the through plate c1, and the heat absorbing block c3 is embedded and movable inside the through plate c1, so There are three petal blocks c2, which are deformable. There are two heat-absorbing blocks c3, which have thermal expansion characteristics. The mouth is deformed in cooperation with the flap c2.

[0042] Wherein, the valve block c2 is provided with an air cushion c21, a spring frame c22, and a side passage block c23. Embedded in the air cushion c21 and movably matched, the air cushion c21 is petal-shaped and has good resilience, the side passage block c23 is provided with an air flow path that gradually expands from the inside to the outside, and the elastic frame c22 is displaced with the pressure of air cushion c21, and the reaction is benefici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com