Double-steel-plate concrete composite shear wall with U-shaped pull rods arranged in staggered mode

A combined shear wall, staggered arrangement technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of large welding deformation, tedious bolt perforation operation, etc., achieve small shear slip, simple and easy installation process, The effect of large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

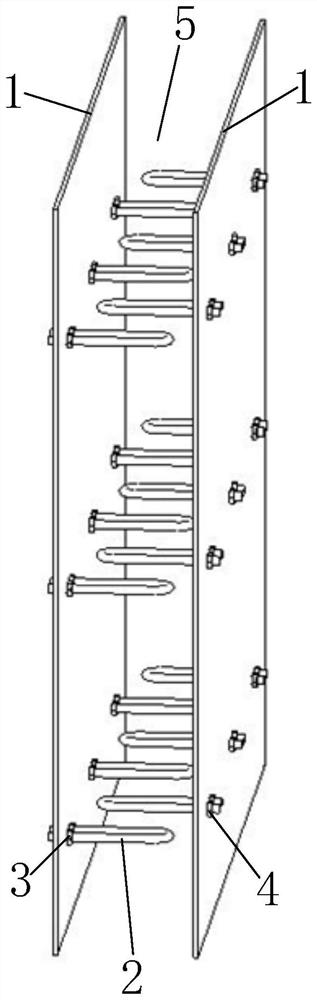

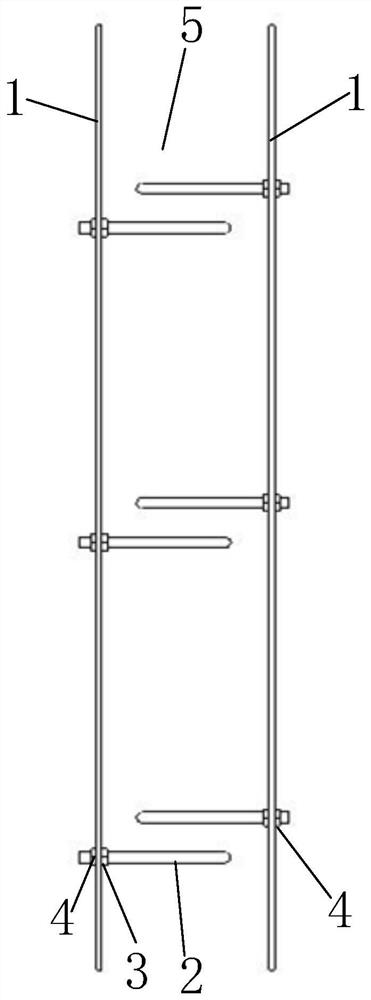

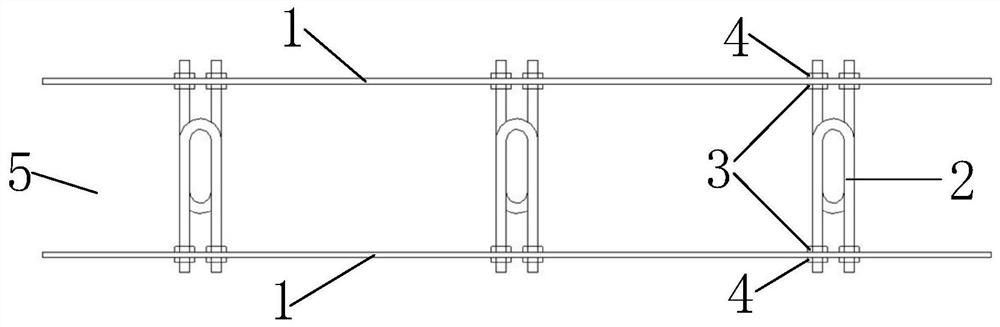

[0025] Such as Figure 1 to Figure 6 As shown, the double steel plate concrete composite shear wall with staggered arrangement of U-shaped tie rods mainly includes steel plates with openings on both sides (1), U-shaped tie rods (2), internal positioning nuts (3), external fixing nuts (4), and filled concrete (5).

[0026] The steel plate (1) with holes on both sides is processed on the basis of the flat steel plate to pass through the U-shaped tie rod. The diameter of the hole is determined according to the diameter of the tie rod, and there should be a gap of no more than 2mm after the tie rod passes through.

[0027] The raw materials of the U-shaped tie rods (2) are metal products with good ductility such as steel bars, screws, steel rods, etc., which are U-shaped by cold working. The clear distance between the U-shaped two limbs should be not less...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com