Wear-resistant water pump

A wear-resistant, water pump technology, applied in the direction of pumps, pump components, non-variable-capacity pumps, etc., can solve the problems of large vibration of the water pump, easy to sink to the bottom, heavy water pipe body, etc., to achieve the effect of easy recovery of the device and easy replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

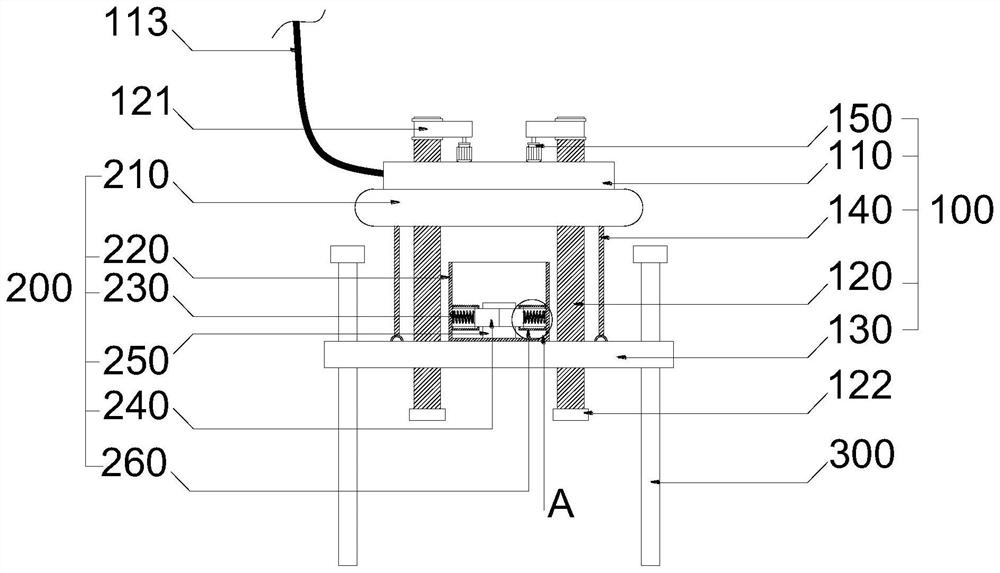

[0039] see figure 1 , the present invention provides a technical solution: a wear-resistant water pump includes a fixing mechanism 100 and a moving mechanism 200 , wherein the moving mechanism 200 is fixed on one side of the fixing mechanism 100 .

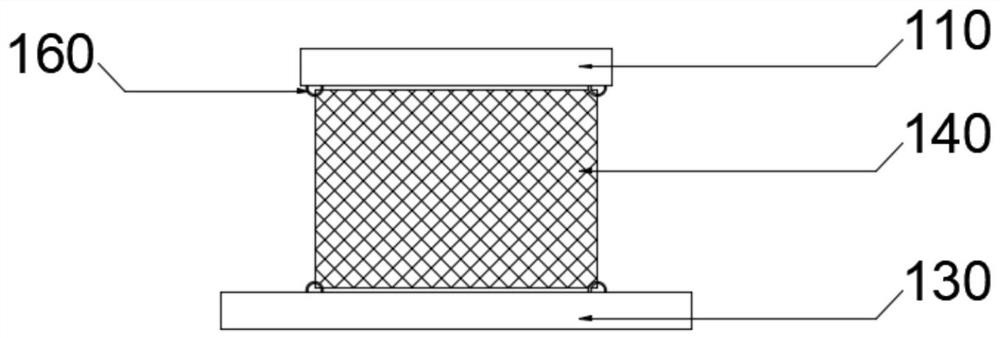

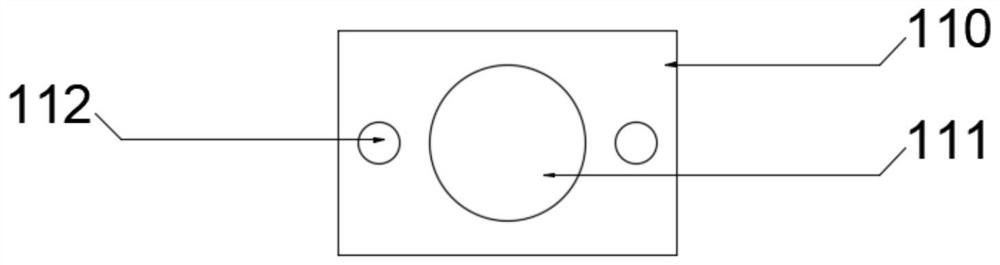

[0040] see figure 1 , 2, 3 and 5, the fixed mechanism 100 includes a fixed plate 110, a threaded rod 120, a base 130, a mesh cover 140 and a motor 150, the middle of the fixed plate 110 is provided with a first through hole 111, and one side of the fixed plate 110 is provided with a cable 113, and the screw thread There are two rods 120, one end of the two threaded rods 120 rotates through the inside of the fixed plate 110, the base 130 is threaded on the threaded rod 120, one end of the mesh cover 140 is fixed on one side of the fixed plate 110, and the surface of the fixed plate 110 is provided with Bearing block 112, fixed plate 110 and base 130 one side are provided with hook 160, net cover 140 two ends are hung on the hook 1...

Embodiment 2

[0043] see figure 1 , the present invention provides a technical solution: a wear-resistant water pump includes a fixing mechanism 100 and a moving mechanism 200 , wherein the moving mechanism 200 is fixed on one side of the fixing mechanism 100 .

[0044] see figure 1 , 2 , 3 and 5, the fixed mechanism 100 includes a fixed plate 110, a threaded rod 120, a base 130, a mesh cover 140 and a motor 150, the middle of the fixed plate 110 is provided with a first through hole 111, and one side of the fixed plate 110 is provided with a cable 113, and the screw thread There are two rods 120, one end of the two threaded rods 120 rotates through the inside of the fixed plate 110, the base 130 is threaded on the threaded rod 120, one end of the mesh cover 140 is fixed on one side of the fixed plate 110, and the surface of the fixed plate 110 is provided with Bearing block 112, fixed plate 110 and base 130 one side are provided with hook 160, net cover 140 two ends are hung on the hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com