An assembly line for automatic bonding of soft magnetic sheets and its realization method

An assembly line and magnetic sheet technology, which is applied in the manufacture of inductors/transformers/magnets, instruments, and measurement of resistance/reactance/impedance, etc., can solve the problems of rising defect rate, crooked product sticking, labor-intensive, etc., and achieve fast switching and reasonable Smooth warehouse management and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

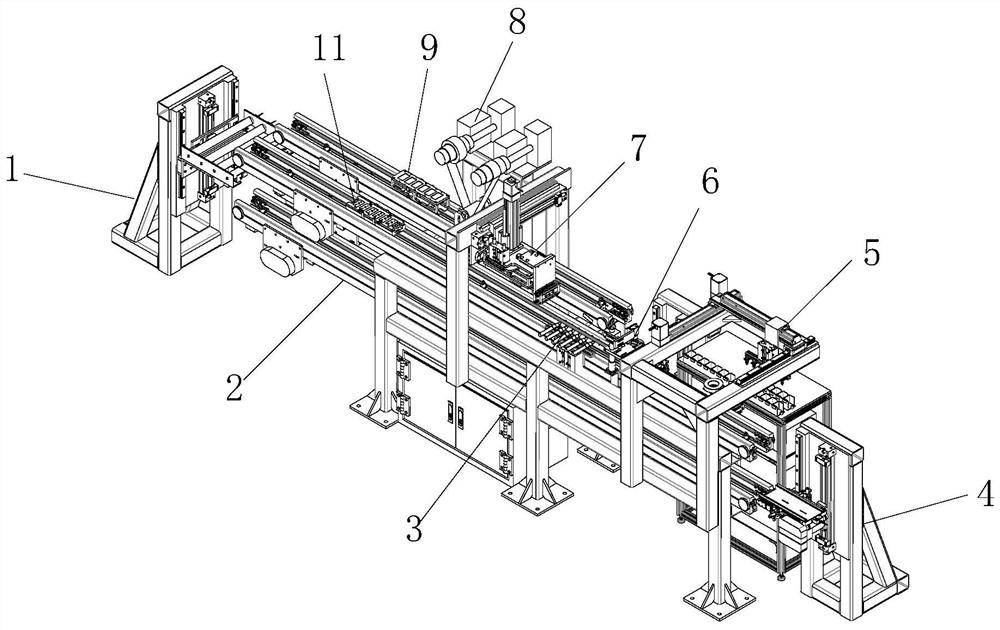

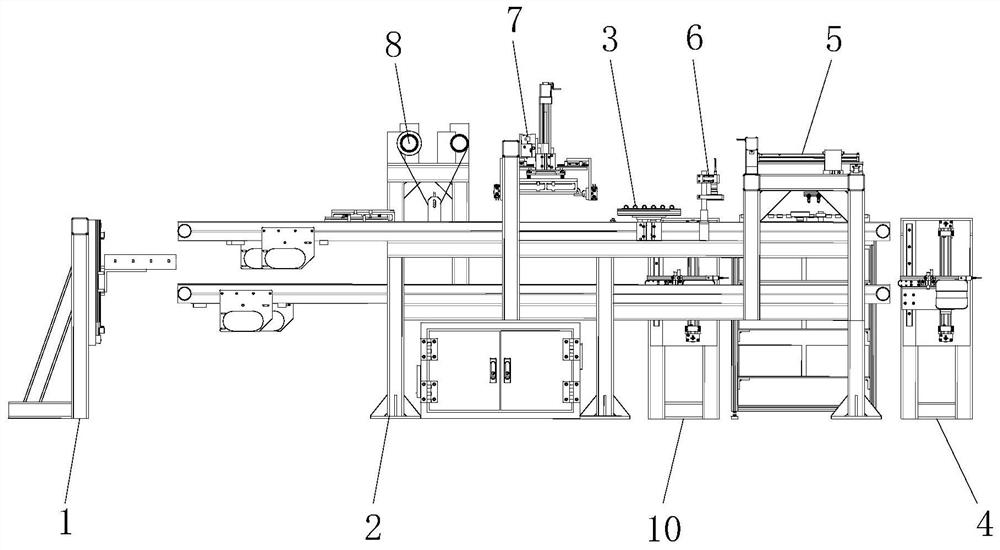

Embodiment 1

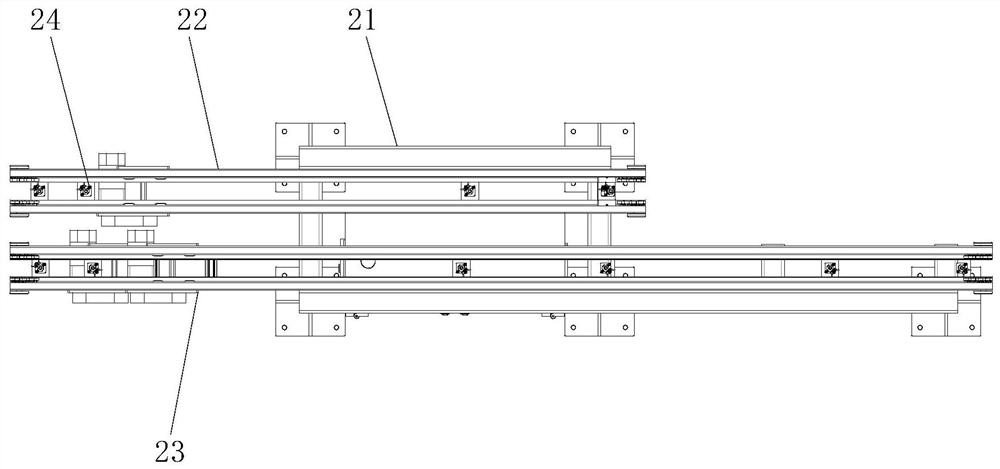

[0054] see Figure 1-16 , the present invention provides the following technical solutions: an assembly line for automatic lamination of soft magnetic magnetic sheets, comprising a conveying line 2, one end of the conveying line 2 is provided with a bilateral lifting platform 1, and the other end of the conveying line 2 is respectively provided with a first unilateral The lifting table 4 and the second unilateral lifting table 10, the magnetic sheet jig 9 and the coil jig 11 are respectively placed above the conveying line 2, and a mucous membrane mechanism 8 is arranged above the conveying line 2, and one side of the mucous membrane mechanism 8 is provided with Transplanting and pasting mechanism 7, one side of the transplanting and pasting mechanism 7 is provided with an inductance sensing mechanism 3, one side of the inductive sensing mechanism 3 is provided with a first defect detection mechanism 6, and one side of the first defect detection mechanism 6 is provided with De...

Embodiment 2

[0076] Further, the implementation method of the assembly line for the automatic lamination of the soft magnetic magnetic sheet of the present invention comprises the following steps:

[0077] (1) Manually place the magnetic sheet on the magnetic sheet fixture 9 according to the specified direction and quantity, and then place the coil on the coil fixture 11 according to the specified direction and quantity. The magnetic sheet fixture 9 and the coil fixture 11 Driven by the conveyor line 2 to flow to the right;

[0078] (2) When the magnetic sheet fixture 9 moves to the bottom of the mucous membrane mechanism 8, the roller 85 of the mucous membrane mechanism 8 presses the transparent tape on the magnetic sheet fixture 9, and the magnetic sheet fixture 9 continues to move to the right. The protective film on the magnetic sheet is peeled off, pasted on the scotch tape and rolled up by the tape take-up roll 83;

[0079] (3) When the magnetic sheet fixture 9 continues to flow to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com