Gas-liquid continuous reaction crystallization device

A technology of reaction crystallization and gas reaction, applied in chemical/physical processes, chemical instruments and methods, etc., can solve problems such as the conversion rate of liquid reactants and the difficulty in recycling and processing liquid products, so as to reduce the risk of sucking back, inhibit agglomeration, and avoid deposition The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

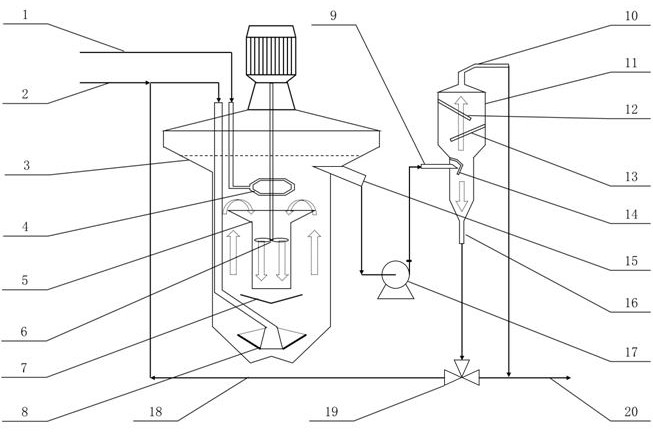

[0018] Such as figure 1 As shown, the gas-liquid continuous reaction crystallization device includes two parts: a reactor and a separator, which are connected by a pump and a pipeline to form a circulation loop. The reactor 3 contains orderly arranged components: the gas distributor 4 connected to the gas reactant feed pipe 1 is located below the liquid surface in the reactor and close to the liquid surface. The guide tube 5 is located under the gas distributor 4 in the middle of the reactor, the propeller agitator 6 is placed in the center of the guide tube 5, the baffle plate 7 is located under the guide tube, and the circulating liquid outlet pipe 8 is located at the bottom of the reactor. The slurry extraction outlet pipe 15 is located near the liquid level area below the upper liquid level of the reactor, and its upper edge is higher than the gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertex angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com