Packaging adhesive film with high PID resistance and preparation method thereof

A packaging film, high resistance technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of long lamination time, slow cross-linking speed, increased haze, etc. Problems, to achieve excellent bonding performance, good effect, high optical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

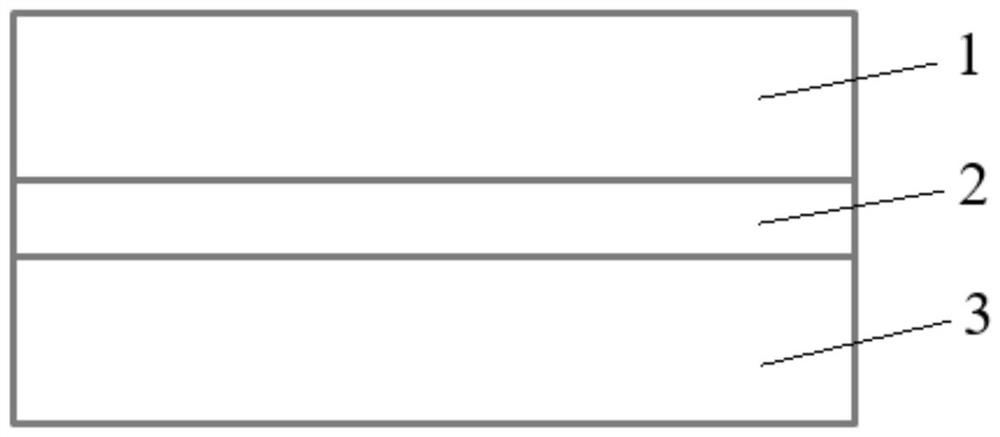

[0054] The highly PID-resistant encapsulating adhesive film of this embodiment includes an upper adhesive film layer, a barrier layer and a lower adhesive film layer arranged in sequence from top to bottom, at least one of the upper adhesive film layer and the lower adhesive film layer is added with anti-hydrolysis Additives and ion traps.

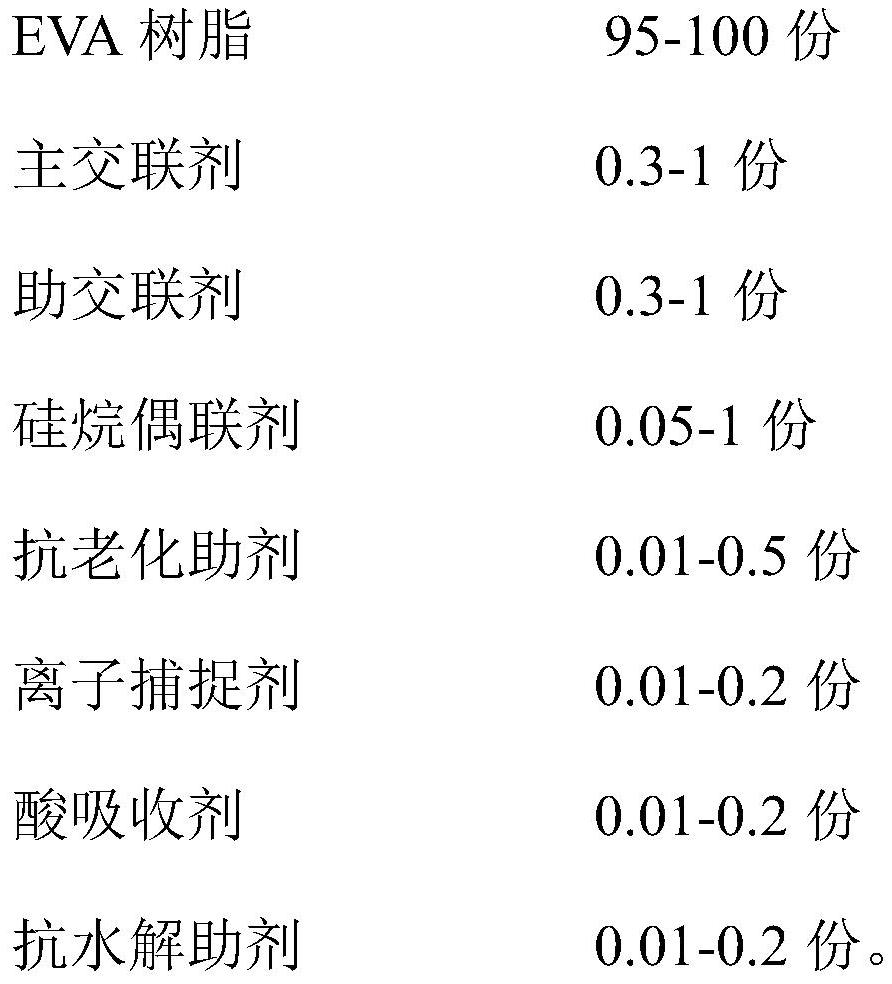

[0055] The thickness of the adhesive film layer is 300 μm, and the adhesive film layer contains the following components in parts by mass:

[0056]

[0057] The barrier layer has a thickness of 50 μm, specifically an ETFE film.

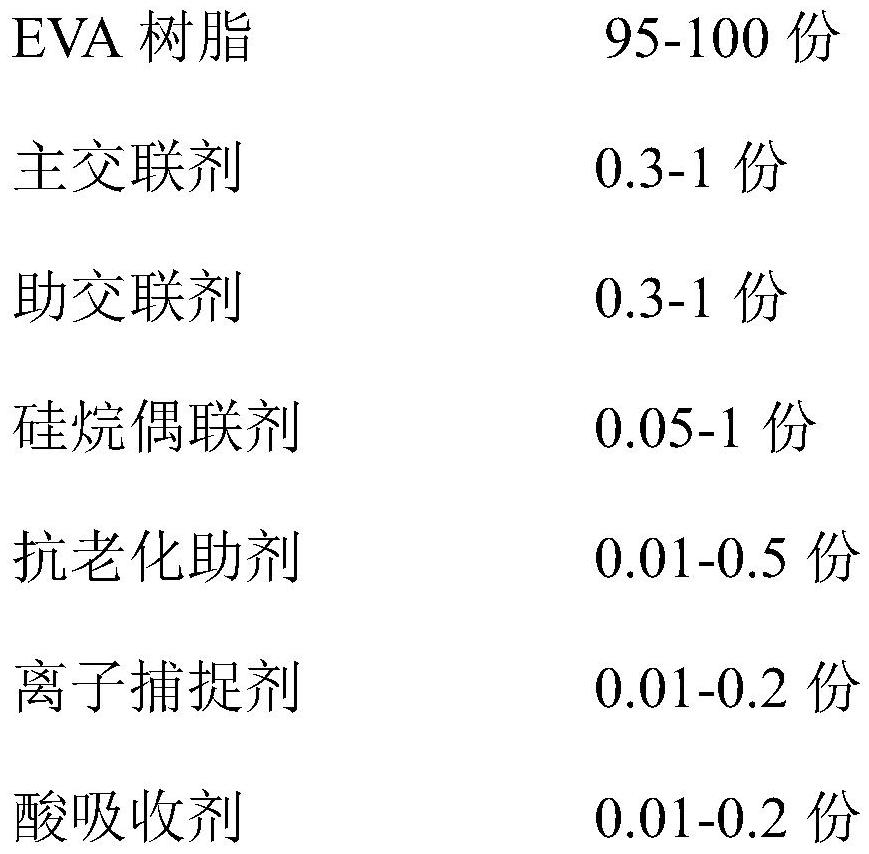

[0058] The thickness of the lower adhesive film layer is 300 μm, and in parts by mass, the lower adhesive film layer comprises the following components:

[0059]

[0060]

[0061] The preparation method of the high-PID-resistant encapsulating adhesive film of this embodiment includes the following steps: purchase a commercially available transparent ETFE film of 50 μm, and cast the upper and lower adhesi...

Embodiment 2

[0063] The highly PID-resistant encapsulating adhesive film of this embodiment includes an upper adhesive film layer, a barrier layer and a lower adhesive film layer arranged in sequence from top to bottom, at least one of the upper adhesive film layer and the lower adhesive film layer is added with anti-hydrolysis Additives and ion traps.

[0064] The thickness of the adhesive film layer is 300 μm, and the adhesive film layer contains the following components in parts by mass:

[0065]

[0066] The barrier layer has a thickness of 50 μm, specifically an ETFE film.

[0067] The thickness of the lower adhesive film layer is 300 μm, and in parts by mass, the lower adhesive film layer comprises the following components:

[0068]

[0069] The preparation method of the high-PID-resistant encapsulating adhesive film of this embodiment includes the following steps: purchase a commercially available transparent ETFE film of 50 μm, and cast the upper and lower adhesive films acc...

Embodiment 3

[0071] The highly PID-resistant encapsulating adhesive film of this embodiment includes an upper adhesive film layer, a barrier layer and a lower adhesive film layer arranged in sequence from top to bottom, at least one of the upper adhesive film layer and the lower adhesive film layer is added with anti-hydrolysis Additives and ion traps.

[0072] The thickness of the adhesive film layer is 300 μm, and the adhesive film layer contains the following components in parts by mass:

[0073]

[0074]

[0075] The barrier layer has a thickness of 50 μm, specifically an ETFE film.

[0076] The thickness of the lower adhesive film layer is 300 μm, and in parts by mass, the lower adhesive film layer comprises the following components:

[0077]

[0078] The preparation method of the high-PID-resistant encapsulating adhesive film of this embodiment includes the following steps: purchase a commercially available transparent ETFE film of 50 μm, and cast the upper and lower adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com