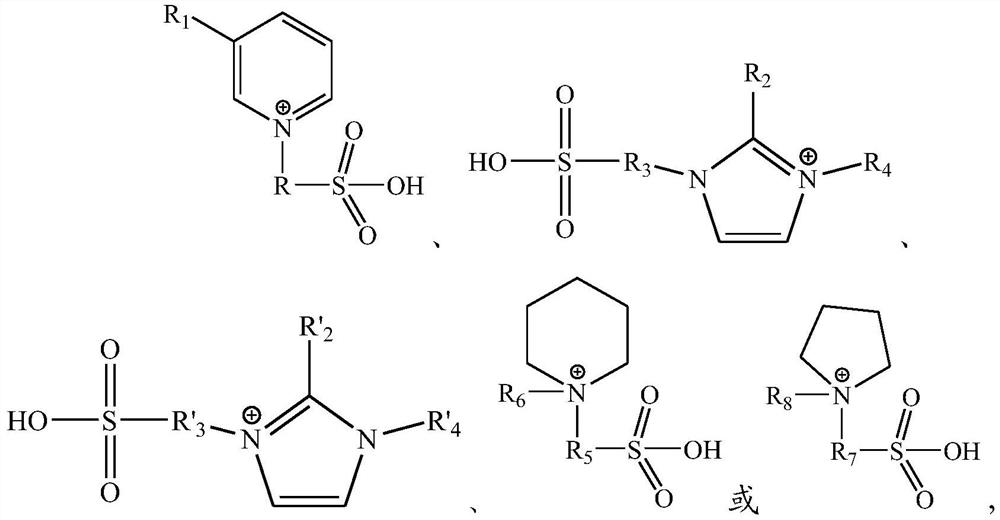

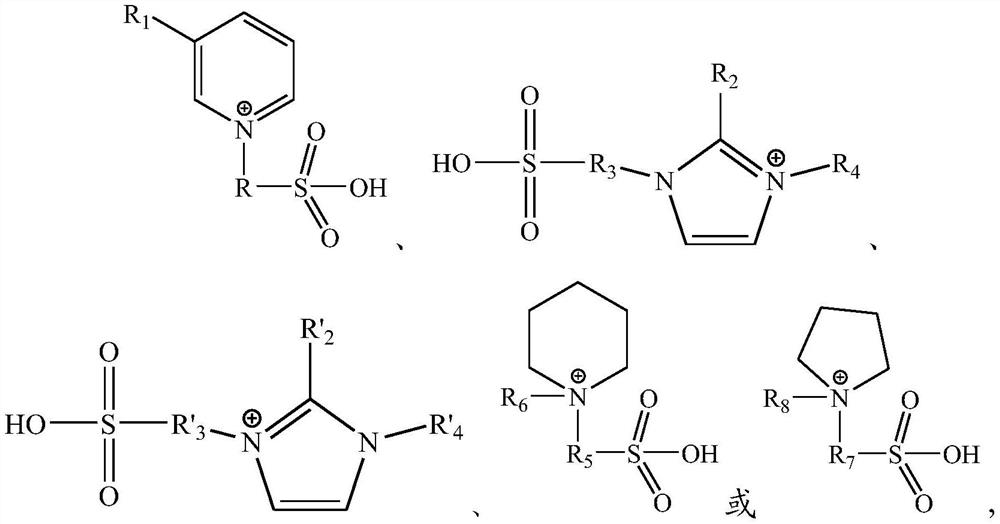

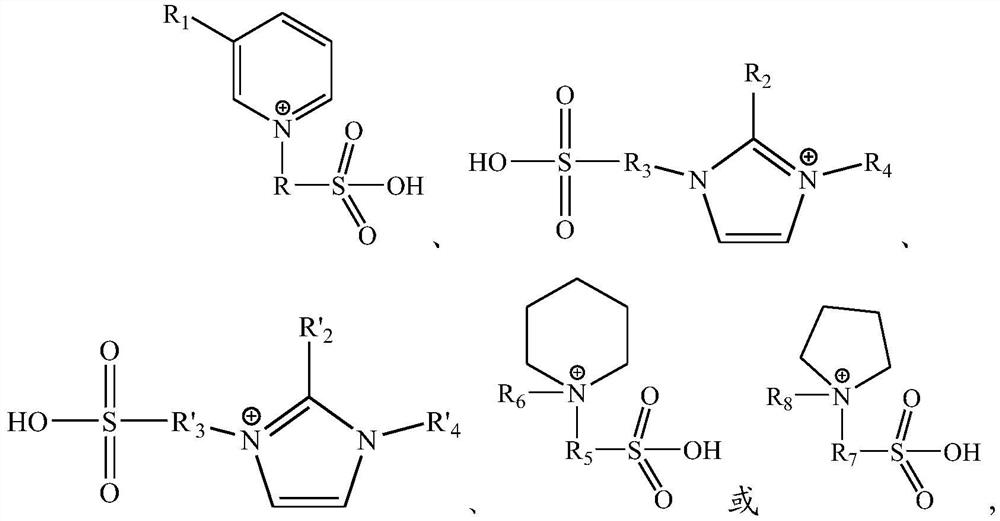

Method for removing glycidyl esters by using ionic liquid

A glycidyl ester and ionic liquid technology, which is applied in the direction of fat oil/fat refining and fat production, can solve the problems that do not conform to the direction of green chemistry advocacy, complex operation, etc., and achieve the effect of direct and efficient removal and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] All the ionic liquids used in the examples were purchased from Shanghai Chengjie Chemical Co., Ltd., with a purity of over 98%.

[0059] Both refined palm oil and refined soybean oil were purchased from Yihai Kerry.

Embodiment 1

[0076] The experimental raw material oil used in this embodiment is the same as that of Comparative Example 1.

[0077] Take 17 parts of experimental raw oil, add 0.5%, 1.0%, 1.5%, 2.0%, 2.5%, 3.0%, 3.5%, 4.0%, 5.0%, 6.0%, 8.0% of the weight of raw oil to it at room temperature , 10.0%, 12.0%, 14.0%, 16.0%, 18.0% or 20.0% of the amount of ionic liquid 1-butylsulfonic acid-3-methylimidazolium bisulfate, namely [BSO 3 Hmim][HSO 4 ], through a high-speed shearing machine at 10,000r·min -1 After shearing for 3 minutes and mixing evenly, stir at 300rpm at 60°C for 1h, and then use a high-speed centrifuge at room temperature to -1 Centrifuge for 5 minutes, separate the oil phase and the ionic liquid phase, and take the upper oil phase to detect the content of glycidyl ester.

[0078]Glycidyl ester detection method refers to AOCS Cd 29c-13 (2017)

[0079]

Embodiment 2

[0081] The experimental raw material oil used in this embodiment is the same as that of Comparative Example 1.

[0082] Get 2 parts of experimental feedstock oils, add the ionic liquid N-sulfonic acid butylpyridinium bisulfate of 1% or 10% amount wherein to the feedstock oil weight at room temperature respectively, namely [BSO 3 HPy][HSO 4 ], through a high-speed shearing machine at 10,000r·min -1 Mix well by shearing for 3 minutes, then stir at 300rpm at 60°C for 1h, and then use a high-speed centrifuge at room temperature to -1 Centrifuge for 5 minutes, separate the oil phase and the ionic liquid phase, and take the upper oil phase to detect the content of glycidyl ester.

[0083] Glycidyl ester detection method refers to AOCS Cd 29c-13 (2017)

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com