A kind of elastic ribbon with massage function

A webbing and elastic technology, used in woven fabrics, textiles, papermaking, treatment and other directions, can solve the problems of poor elastic performance and air permeability, poor comfort, single function, etc., to extend service life and improve anti-aging performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

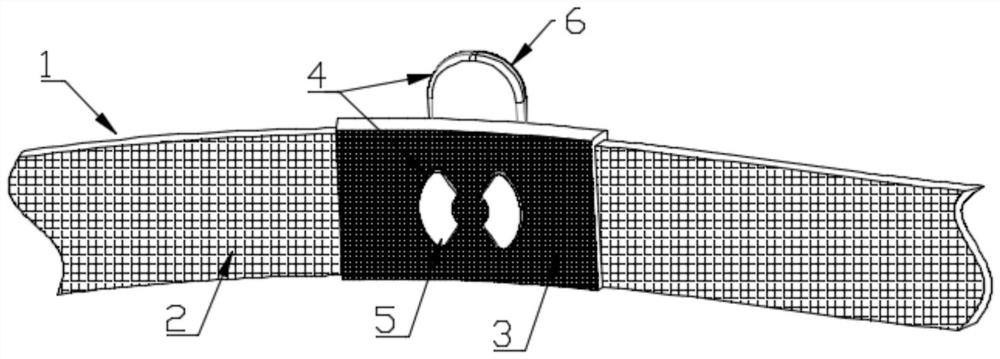

[0029] A kind of elastic webbing 1 with massage function, described elastic webbing 1 comprises webbing main body 2 and the massaging component 4 that is bonded in its inner side by adhesive tape 3; Wherein, described webbing main body is weaving structure; And webbing main body is made of The parts by weight are composed of modified PA6 fiber of 35, polypropylene fiber of 15, modified polyester fiber of 8, bamboo charcoal fiber of 12 and spandex fiber of 4; controller6.

[0030] The preparation method of modified PA6 fiber comprises the following steps

[0031] 1. Put an appropriate amount of mixed powder into the mixed solution at a material-to-liquid ratio of 0.06g / mL. After mixing and stirring evenly, raise the temperature of the resulting mixed component to 50°C, and keep it warm at this temperature for 5 hours; During the reaction process, the mixed components were mechanically stirred for 5 minutes every 1 hour; after the reaction was completed, the mixed powder was fi...

Embodiment 2

[0042] The difference between the elastic webbing with massage function provided in this embodiment and that of Example 1 is that the specific proportions of the fiber components contained in the webbing body itself are different, and the specific preparation of the modified PA6 fiber and the modified polyester fiber is different. Processes vary, specifically:

[0043] The webbing body is composed of 40 parts by weight of modified PA6 fiber, 20 parts of polypropylene fiber, 10 parts of modified polyester fiber, 15 parts of bamboo charcoal fiber and 6 parts of spandex fiber;

[0044] The preparation method of modified PA6 fiber comprises the following steps

[0045] 1. Put an appropriate amount of mixed powder into the mixed solution at a material-to-liquid ratio of 0.08g / mL, and after mixing and stirring evenly, raise the temperature of the resulting mixed component to 55°C, and keep it warm at this temperature for 6 hours; During the reaction process, the mixed components we...

Embodiment 3

[0054] The difference between the elastic webbing with massage function provided in this embodiment and that of Example 1 is that the specific proportions of the fiber components contained in the webbing body itself are different, and the specific preparation of the modified PA6 fiber and the modified polyester fiber is different. Processes vary, specifically:

[0055] The webbing body is composed of 50 parts by weight of modified PA6 fiber, 25 parts of polypropylene fiber, 12 parts of modified polyester fiber, 18 parts of bamboo charcoal fiber and 8 parts of spandex fiber;

[0056] The preparation method of modified PA6 fiber comprises the following steps

[0057] 1. Put an appropriate amount of mixed powder into the mixed solution at a material-to-liquid ratio of 0.1g / mL, and after mixing and stirring evenly, raise the temperature of the resulting mixed component to 60°C, and keep it warm at this temperature for 8 hours; During the reaction process, the mixed components wer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com