Variable compression ratio connecting rod control device

A control device and compression ratio technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of increased processing cost, processing problems, and high processing accuracy requirements, and achieve convenient control, simple structure, and easy implementation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The accompanying drawings only express examples and should not be interpreted in a restrictive manner. The present invention will be described in detail below in conjunction with the accompanying drawings:

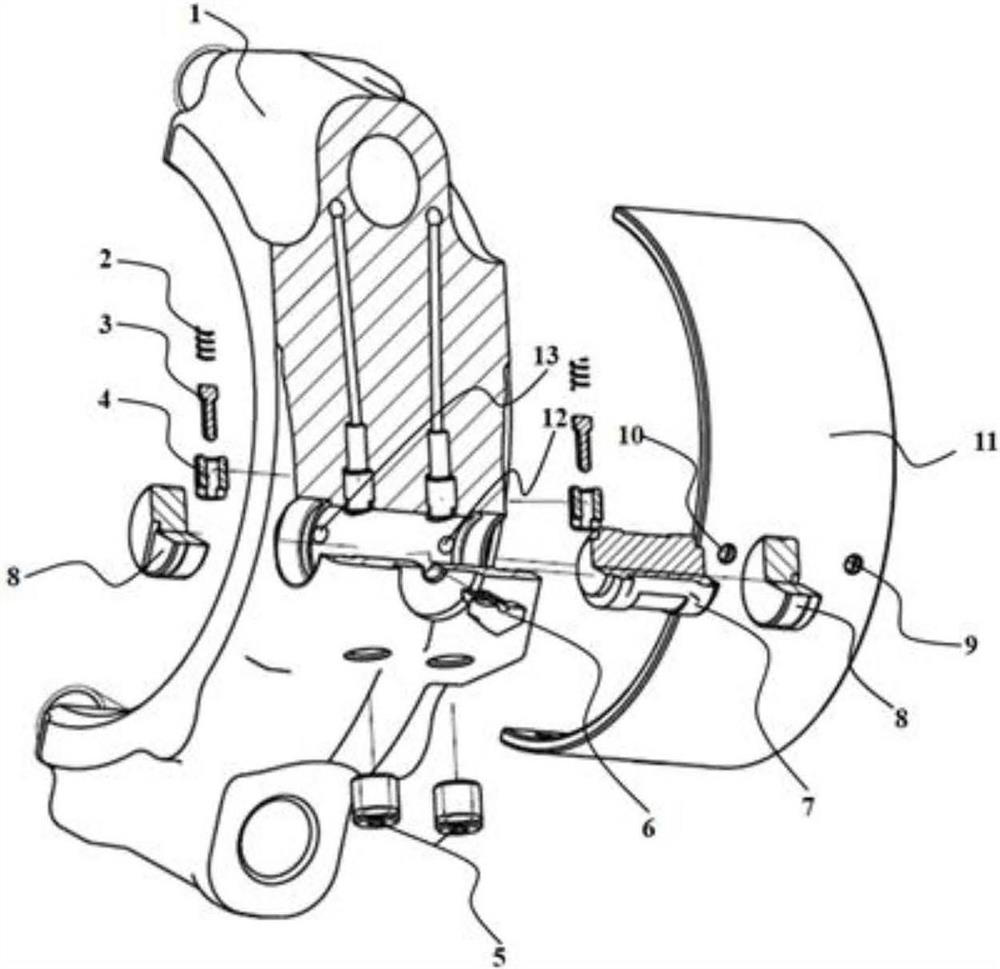

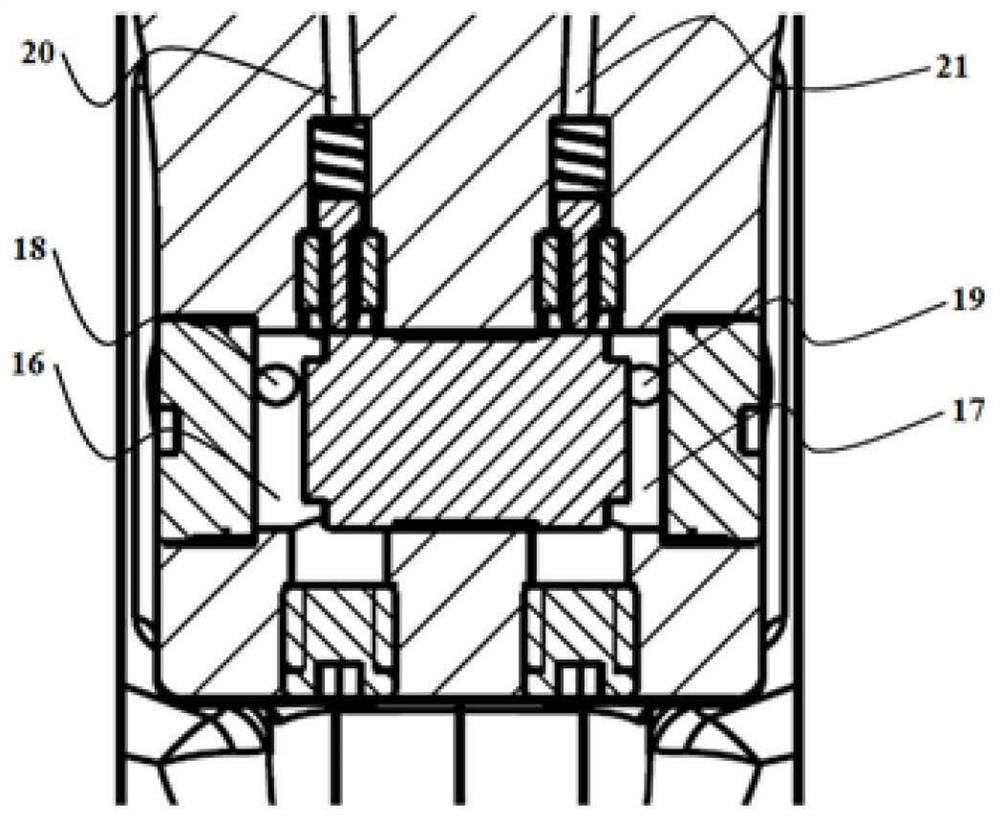

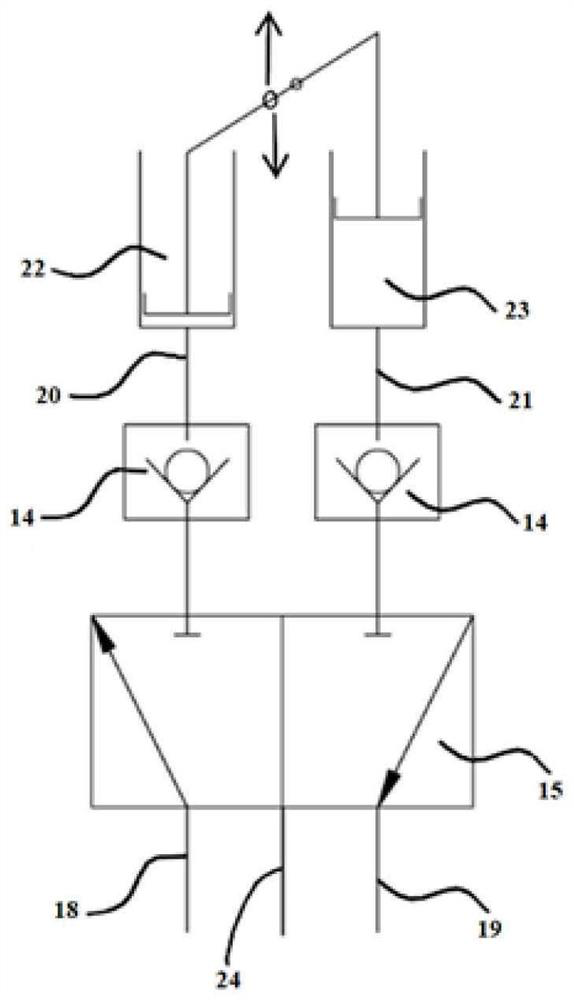

[0034] refer to figure 1 , the hydraulic automatic control device described in the present invention is arranged in the connecting rod cover, a variable compression ratio connecting rod control device, mainly composed of a connecting rod cover 1, a thimble check valve 14, a five-way switching valve 15 and a double oil The connecting rod lower bearing bush 11 is composed of the one-way valve spring 2, the one-way valve thimble 3 and the one-way valve seat 4 together to form the thimble type one-way valve 14; The screw 6, the spool 7 and the spool plug 8 together form a five-way switching valve 15. The lower bearing bush 11 of the double oil passage connecting rod is provided with an oil inlet A 9 and an oil inlet B10 at different positions. The oil inlet A communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com