A kind of preparation method of titanium dioxide@silver spherical composite material and its application

A composite material, titanium dioxide technology, applied in the directions of titanium dioxide, titanium oxide/hydroxide, botanical equipment and methods, etc., can solve problems such as performance to be further improved, irregular material morphology, etc., to achieve large-scale factory production. , the preparation method is simple and effective, and the effect of excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

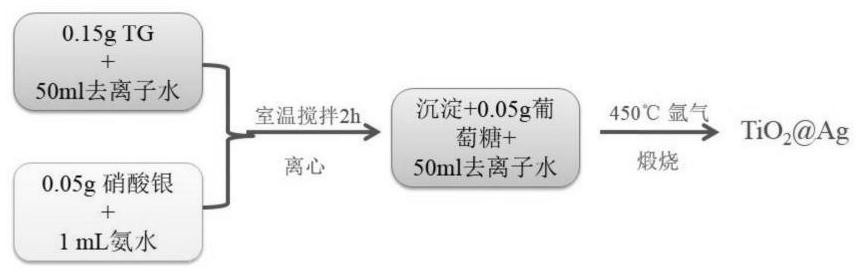

[0029] (1) Dissolve 0.15 g of n-butyl titanate in 50 mL of deionized water to obtain an aqueous solution of n-butyl titanate, stir, and dropwise add 30 mL of mercaptoethanol-arginine-water solution (mass ratio is 0.2:1: 40), continue to stir for 30min to obtain the precursor solution for later use;

[0030] (2) Add 0.05 g of silver nitrate and 1 mL of ammonia water to the precursor solution, stir at room temperature for 2 hours, centrifuge the precipitate, dissolve it in 50 mL of deionized water, add 0.05 g of glucose, stir for 2 well, centrifuge, wash, and dry Then n-butyl titanate@Ag intermediate is obtained;

[0031] (3) The dried n-butyl titanate@Ag was calcined in a tube furnace at 450 °C under Ar atmosphere for 2 h to obtain TiO2@Ag composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com