Method for modifying positive electrode material by using nitrogen-containing compound, and application of positive electrode material in lithium ion battery

A positive electrode material and nitrogen compound technology, applied in the field of secondary battery positive electrode materials, can solve the problems of low rate performance and poor cycle life of the positive electrode material transition metal oxide, and achieve low modification cost, improved kinetics, and a simple and mild synthesis method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 10g of Li 1.25 mn 0.625 Ni 0.125 o 2 The positive electrode material powder was added to 100 mL of 1 mol / L aqueous urea solution, and stirred magnetically at 90°C for 5 hours until dry.

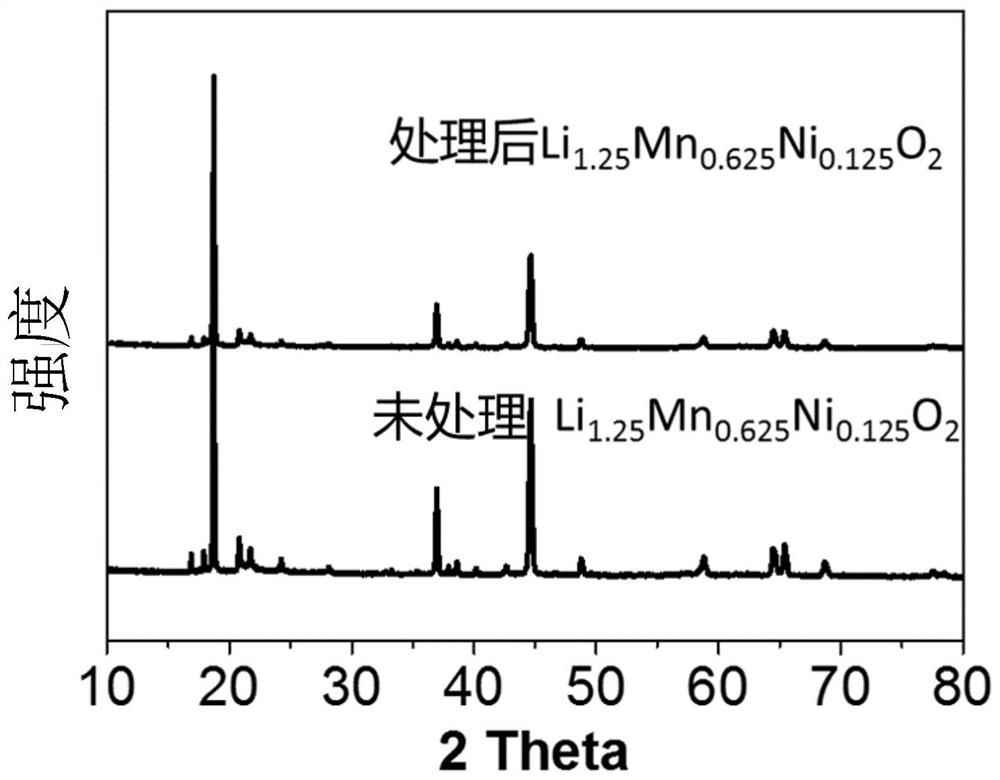

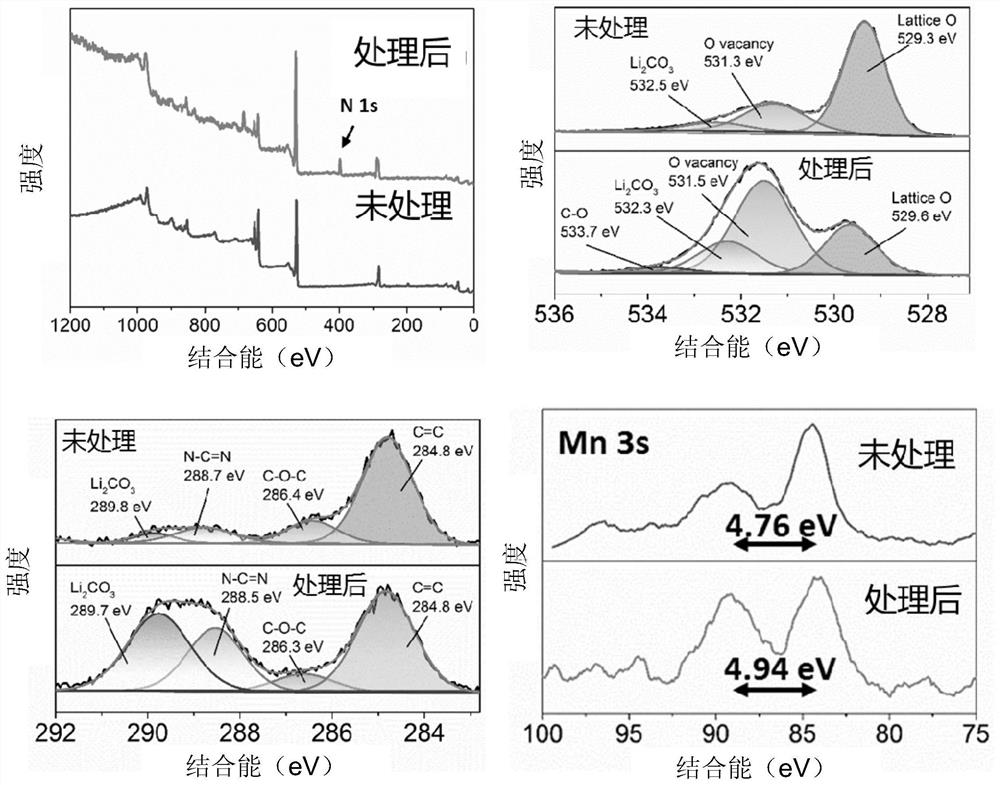

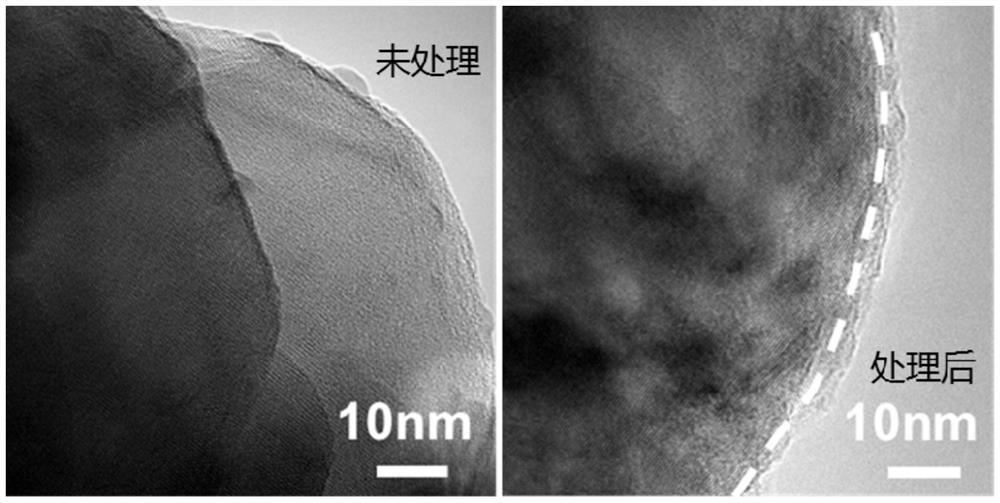

[0033] Will Li 1.25 mn 0.625 Ni 0.125 o 2 The mixture with urea was heated in a nitrogen atmosphere muffle furnace at 400°C for two hours. Such as figure 1 As shown, the urea treatment did not change the phase of the material body, and there was no obvious difference in the crystal diffraction peaks before and after treatment. Such as figure 2 As shown, it can be seen that the photoelectron spectrum peak of N appears on the surface of the material, and the high-resolution photoelectron spectroscopy analysis shows that the characteristic peak of carbonitride appears on the surface of the material, and the manganese ion is partially reduced, accompanied by oxygen vacancies and Li 2 CO 3 The appearance of characteristic peaks confirmed the occurrence of urea modification. Suc...

Embodiment 2

[0036] 10g of ternary cathode material LiNi 0.6 mn 0.2 co 0.2 o 2 The powder was ball milled with 2 g of melamine at 300 rpm for 6 hours to obtain a mixture powder, and the mixture powder was heated in an air atmosphere muffle furnace at 500° C. for 5 hours. The modified ternary cathode material is obtained. Such as Figure 4 As shown, the crystal structure of the ternary material did not change after modification. The electrochemical stability of the modified material also showed a certain improvement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com