Microphone packaging structure and method for preparing microphone packaging structure

A packaging structure and microphone technology, which is applied to sensors, electrostatic transducers, microphones, electrical components, etc., can solve the problems of cracking of the welding structure of the cover body and the substrate, the decrease of sensitivity and signal-to-noise ratio, and the cracking of the silicon diaphragm. Small size, improved sensitivity and signal-to-noise ratio, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0047] see figure 1 , the present embodiment provides a microphone package structure 100, which has a small package size, can avoid the problem of substrate warping, and can prevent the silicon diaphragm from being broken due to high-intensity sound pressure impact, effectively protecting the silicon diaphragm, and The sensitivity, signal-to-noise ratio, and frequency response of the silicon microphone are improved, and the performance of the silicon microphone is improved.

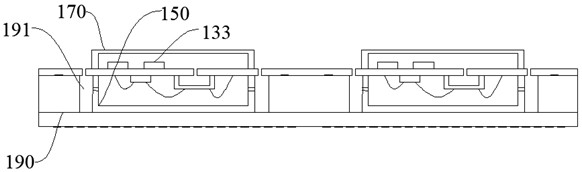

[0048] The microphone packaging structure 100 provided in this embodiment includes a functional substrate 110, a silicon microphone chip 130, a first cover 150, a second cover 170, and a carrier substrate 190. The carrier substrate 190 is provided with an accommodating groove 191, and the silicon microphone The chip 130 is mounted on one side of the functional substrate 110, and the first cover 150 is also mounted on one side of the functional substrate 110, and is covered on the silicon chip 130, and the...

no. 2 example

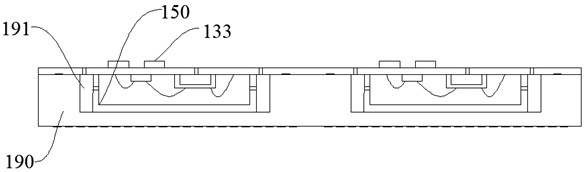

[0062] see figure 2, this embodiment provides a microphone packaging structure 100, its basic structure and principle and the technical effect produced are the same as those of the first embodiment, for a brief description, the parts not mentioned in this embodiment can refer to the first embodiment corresponding content. The difference between this embodiment and the first embodiment lies in the opening position of the first back sound hole 111 .

[0063] In this embodiment, a plurality of first sound-rearing holes 111 are provided on the bottom wall of the carrying substrate 190 and the accommodating groove 191, and the plurality of first sound-rearing holes 111 on the functional substrate 110 surround the first cover. Around the body 150 and the second cover 170, a plurality of first back sound holes 111 located on the bottom wall of the accommodation groove 191 surround the projection of the first cover 150 on the bottom wall of the accommodation groove 191, And each of...

no. 3 example

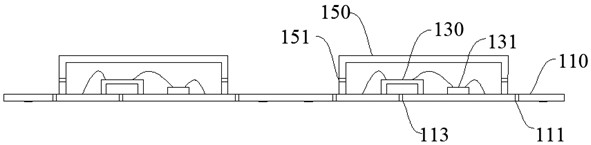

[0068] see image 3 , this embodiment provides a microphone packaging structure 100, its basic structure and principle and the technical effect produced are the same as those of the first embodiment, for a brief description, the parts not mentioned in this embodiment can refer to the first embodiment corresponding content. The difference between this embodiment and the first embodiment lies in the opening position of the first back sound hole 111 .

[0069] In this embodiment, the carrier substrate 190 is provided with a plurality of first sound-rearing holes 111 , and the plurality of first sound-rearing holes 111 are arranged on the bottom wall of the accommodating groove 191 and surround the first cover 150 Around the projection on the bottom wall of the accommodating groove 191 , the plurality of first sound-rearing holes 111 correspond to between the first cover 150 and the sidewall of the accommodating groove 191 .

[0070] In this embodiment, the first cover 150 is sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com