Automatic spraying and shifting device and method for prebaked anode forming

An automatic spraying and prebaking anode technology, which is applied in the direction of material forming presses, manufacturing tools, presses, etc., can solve the problems of unstable quality of anode carbon blocks, fatigue and irritability of operators, and poor working environment, etc. Achieve the effects of reducing labor intensity, simple and feasible process method, and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

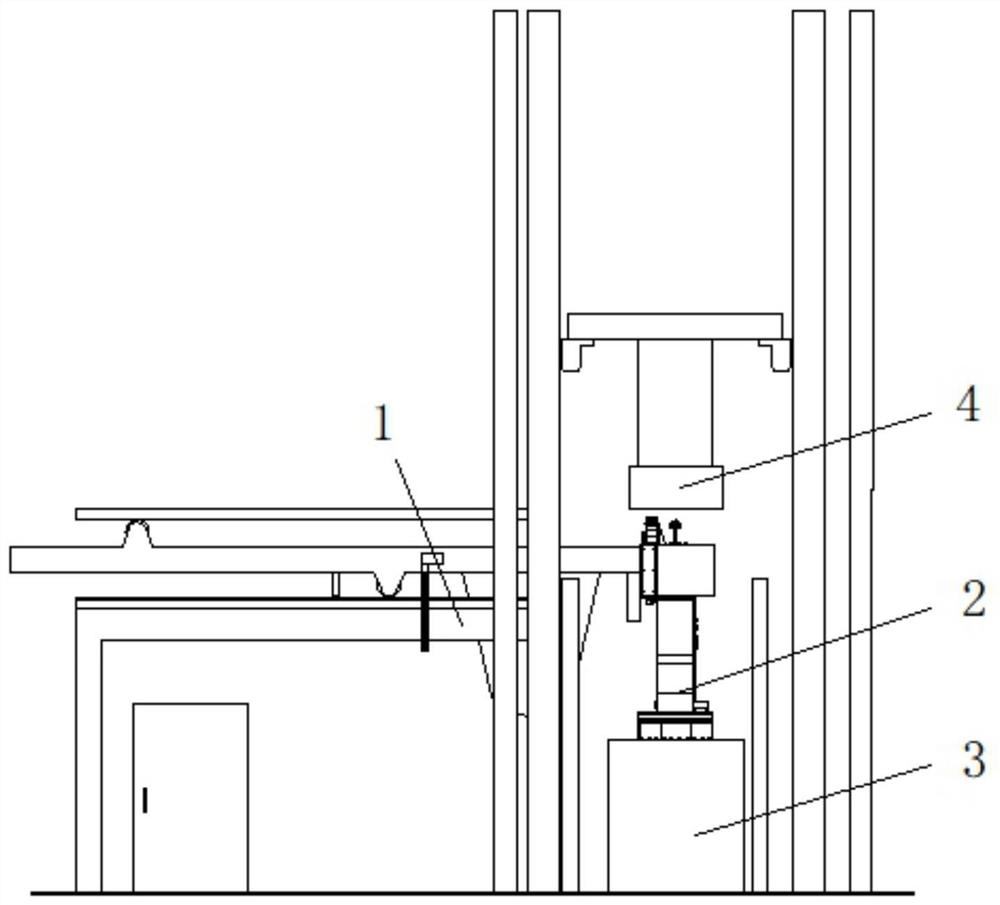

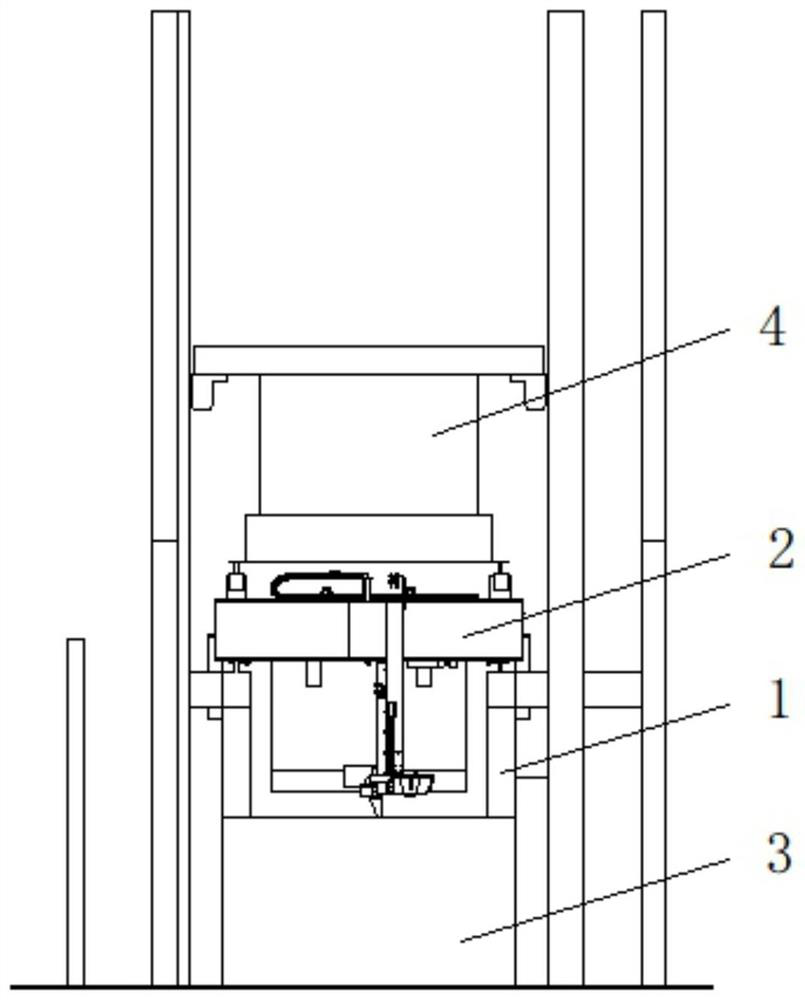

[0038] see Figure 1-3 , the present invention provides a technical solution: an automatic spraying and feeding device for prebaked anode forming, including a molding machine hopper 1, an automatic spraying and feeding device 2 is fixedly installed on the molding machine hopper 1, and an automatic spraying and feeding device 2 is fixed on the molding machine hopper 1. The forming machine mold 3 is provided under the device 2, and the pressure weight 4 is provided above the automatic spraying and feeding device 2;

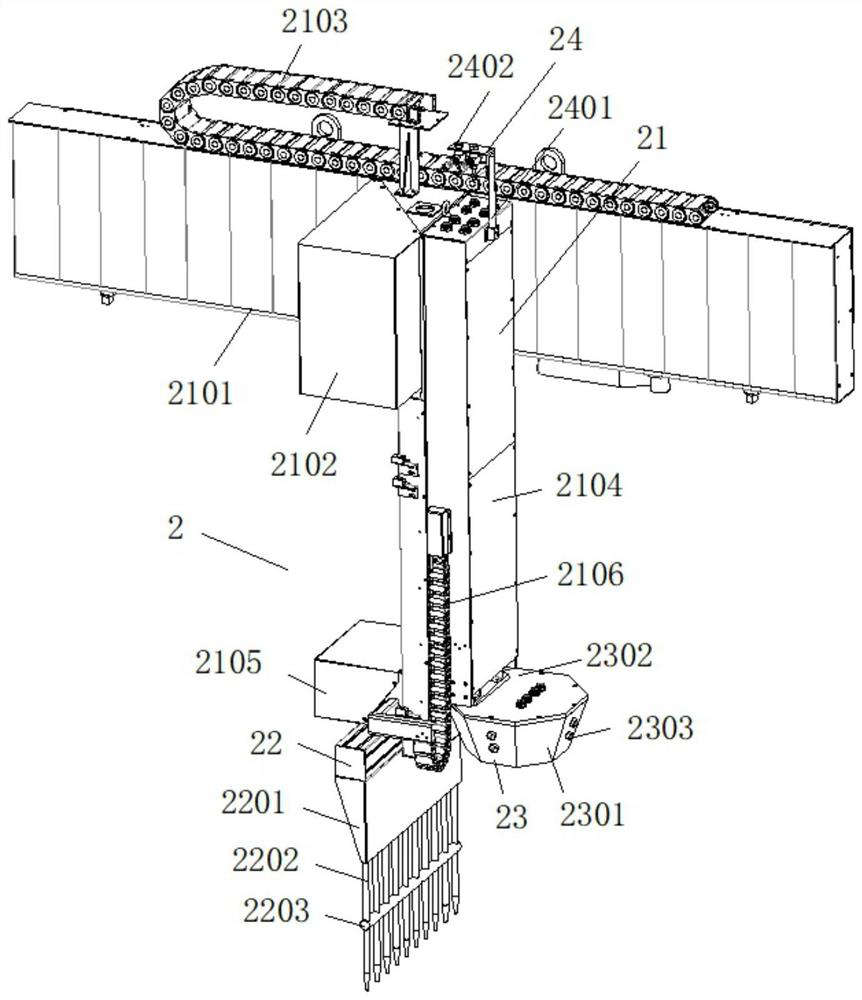

[0039] The automatic spraying device 2 includes a manipulator assembly 21, the free end of the manipulator assembly 21 bottom is fixedly equipped with a rake assembly 22, the free end of the manipulator assembly 21 bottom is equipped with a spray plate assembly 23, and the spray plate assembly 23 is located on the dial On the right side of the top of the material rake assembly 22, the top of the manipulator assembly 21 is equipped with a nozzle assembly 24. The mech...

Embodiment 2

[0057] see Figure 1-3 , an automatic spraying device for prebaked anode forming, the manipulator assembly 21 includes an X-axis moving assembly 2101, a Z-axis moving assembly 2104 is installed on the free end of the X-axis moving assembly 2101, and a Z-axis moving assembly 2104 is fixedly installed with The X-axis servo motor 2102, the X-axis servo motor 2102 is connected with the X-axis moving assembly 2101, the X-axis moving assembly 2101 is equipped with an X-axis drag chain 2103, and the Z-axis moving assembly 2104 is fixedly installed with a Z-axis servo motor 2105, Z The output end of the axis servo motor 2105 is connected to the Z-axis moving assembly 2104, and the Z-axis moving assembly 2104 is equipped with a Z-axis drag chain 2106. The operation of the manipulator assembly 21 can drive the rake assembly 22 and the spray plate assembly 23 to realize The material feeding and following spraying operations are ingeniously designed in terms of the realized mechanical mec...

Embodiment 3

[0060] An automatic spraying method for prebaked anode forming. The multiple nozzles spraying into the mold is a spraying plate assembly. Two nozzles are installed along different angles to spray cutting fluid and anti-wear hydraulic oil respectively. The rake is a multi-tooth nail rake with a ribbed structure. The mechanism that drives the nozzle and the rake to move automatically is a servo motor-driven manipulator assembly that can move along the X and Z directions. The nozzle is equipped with a spray The plate mechanism is connected to the manipulator assembly through a cylinder that can move up and down, and the rake is connected to the Z-axis servo motor on the manipulator assembly through an aluminum profile. Artificial labor intensity improves production efficiency and product quality, and is suitable for large-scale promotion.

[0061] During use, the entire automatic spraying and shifting device 2 is installed on the front of the molding machine hopper 1, and can mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com