Method for producing high-concentration compound fertilizer by utilizing ammonium phosphate plant

A production method and technology of compound fertilizer, applied to ammonium orthophosphate fertilizer, phosphate fertilizer, ammonium salt fertilizer, etc., can solve the problems of high energy consumption, complex process, large investment, etc., achieve good economic benefits, easy to implement, and simple process method Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

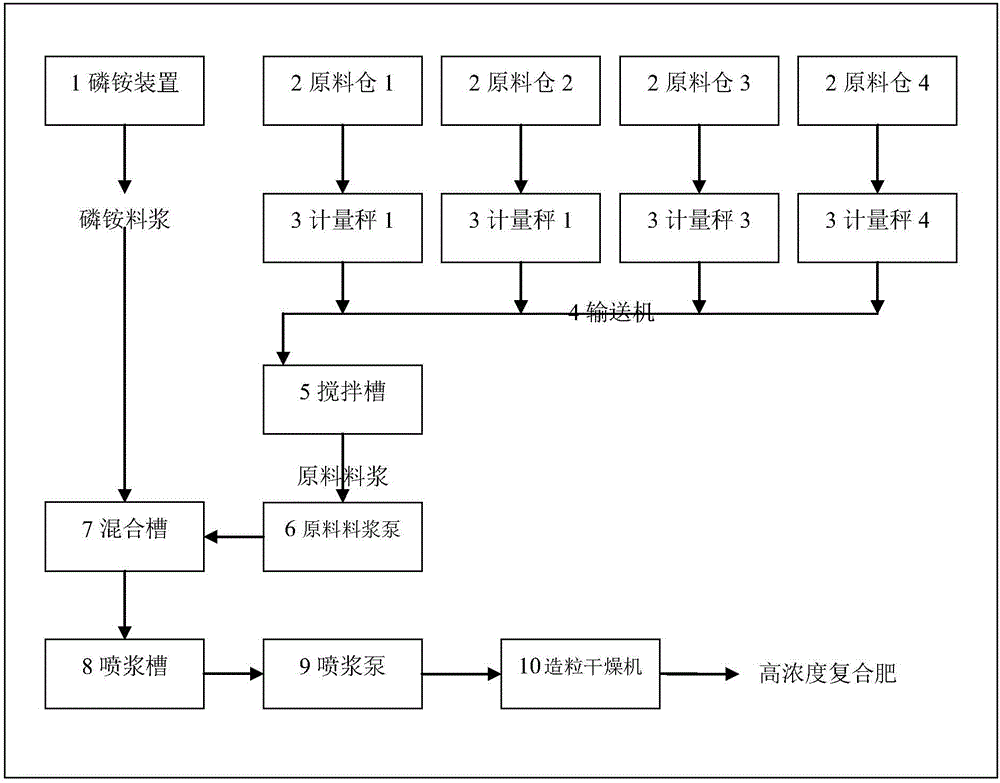

[0012] Utilize ammonium phosphate device 1, produce ammonium phosphate slurry, obtain neutralization degree 1.40~1.50, specific gravity 1.45~1.50, the ammonium phosphate slurry of water content weight percentage (the same below) 25~30%, slurry dry base material contains N: 14.5% with P 2 o 5 : 45.5%; using the additional raw material device, potassium fertilizer, nitrogen fertilizer, phosphate fertilizer and other fertilizers or elements are respectively passed through the raw material warehouse 2 (2~1 to 2~4, etc.), and through the weighing scale 3 (3~1 to 3~4 etc.) ) after metering, transported to the stirring tank 5 through the conveyor 4, and the consumption ratio of potassium sulfate and ammonium sulfate is a weight ratio of 2:1. The raw material is mixed with the added tail suction water in the stirring tank 5 to a raw material slurry with a concentration weight percentage (the same below) of 65 to 75%, and then transported by the raw material slurry pump 6 and then add...

Embodiment 2

[0014] Use ammonium phosphate device 1 to produce ammonium phosphate slurry to obtain ammonium phosphate slurry with a neutralization degree of 1.40-1.50, a specific gravity of 1.45-1.50, and a water content of 25-30%. The dry base material of the slurry contains N: 14.5%, and P 2 o 5 : 43.5%; using the additional raw material device, potassium fertilizer, nitrogen fertilizer, phosphate fertilizer and other fertilizers or elements are respectively passed through the raw material warehouse 2 (2~1 to 2~4, etc.), and through the weighing scale 3 (3~1 to 3~4 etc.) ) after metering, transported to the stirring tank 5 through the conveyor 4, and the consumption ratio of potassium sulfate and ammonium sulfate is a weight ratio of 1.9:1.2. The raw material is mixed with the added tail suction water in the stirring tank 5 to form a raw material slurry with a concentration of 65-75%, and then the raw material slurry pump 6 is transported and metered, and then added to the ammonium phosp...

Embodiment 3

[0016] Use ammonium phosphate device 1 to produce ammonium phosphate slurry to obtain ammonium phosphate slurry with a neutralization degree of 1.40-1.50, a specific gravity of 1.45-1.50, and a water content of 25-30%. The dry base material of the slurry contains N: 14.5%, and P 2 o 5 : 45.3%; using the additional raw material device, potassium fertilizer, nitrogen fertilizer, phosphate fertilizer and other fertilizers or elements are respectively passed through the raw material warehouse 2 (2~1 to 2~4, etc.), and through the weighing scale 3 (3~1 to 3~4 etc.) ) After metering, it is transported to the stirring tank 5 through the conveyor 4, and the raw materials are all potassium sulfate. The raw material is mixed with the added tail suction water in the stirring tank 5 to form a raw material slurry with a concentration of 70-75%, and then transported by the raw material slurry pump 6 after metering, and then added to the ammonium phosphate slurry and the raw material slurry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com