Charging gun structure based on graphene material

A charging gun and graphene technology, applied in the field of charging guns, can solve problems such as temperature rise and impact on service life, and achieve the effects of increasing electrical conductivity, improving heat dissipation, and stabilizing dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

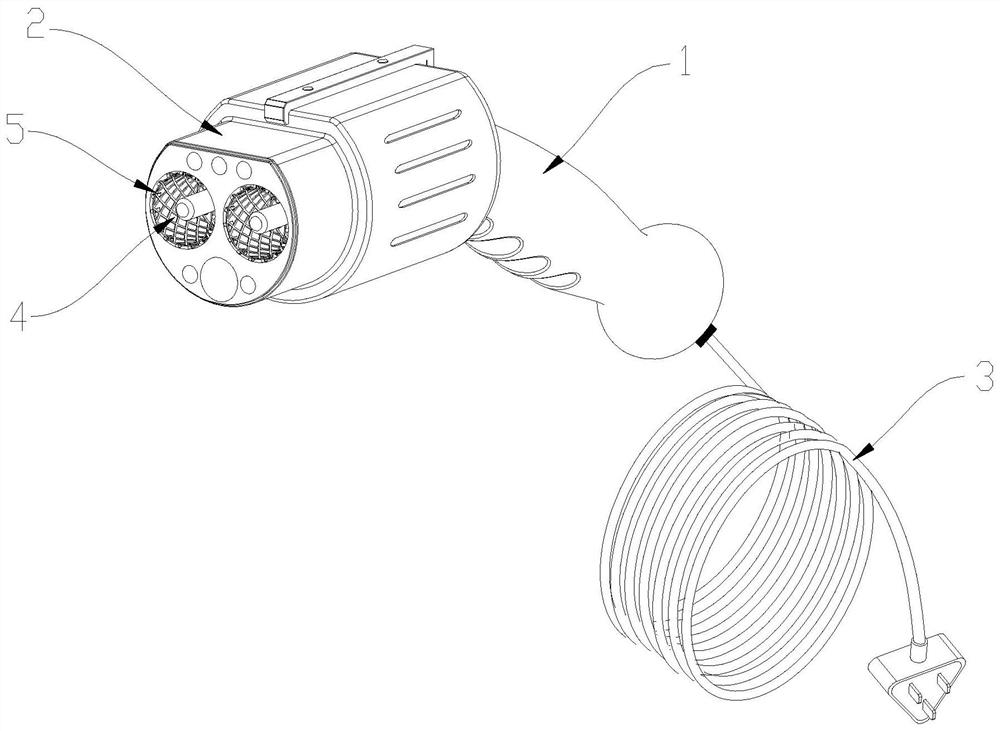

[0020] Such as figure 1 As shown, a graphene-based charging gun structure includes a charging gun body 1 , a charging connector 2 arranged at the front end of the charging gun body 1 , and a charging cable 3 connected to the rear end of the charging gun body 1 .

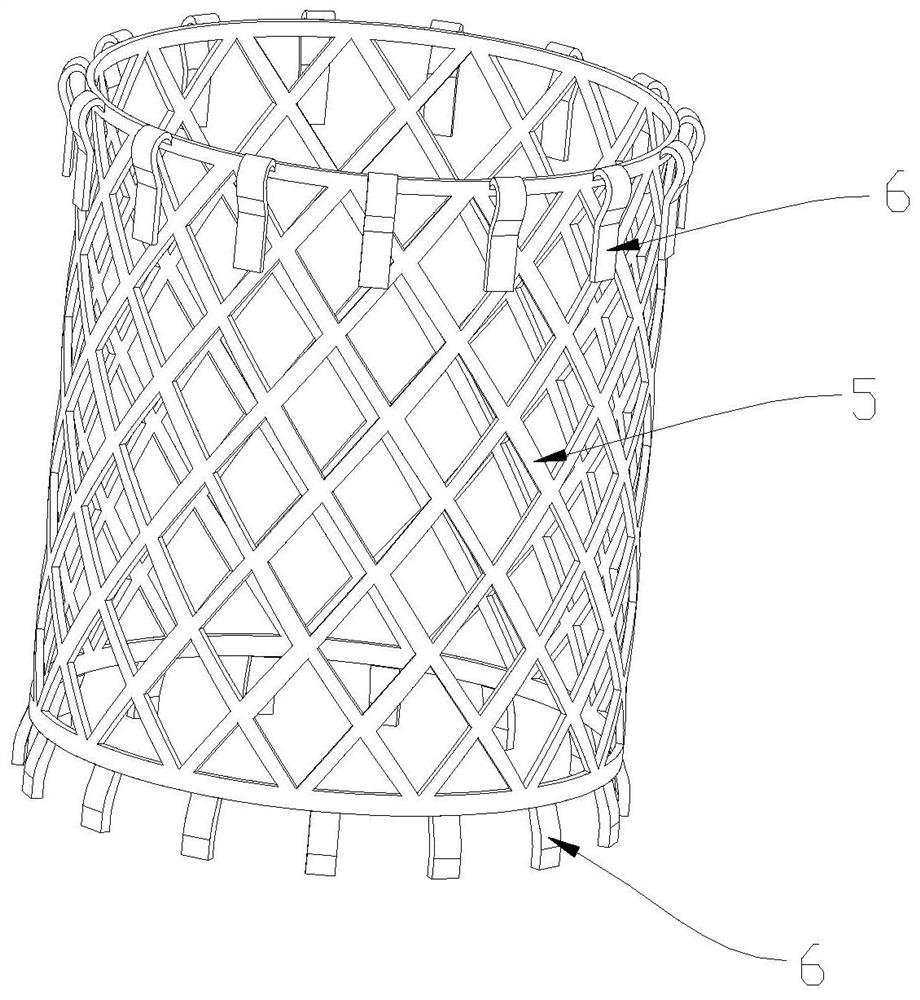

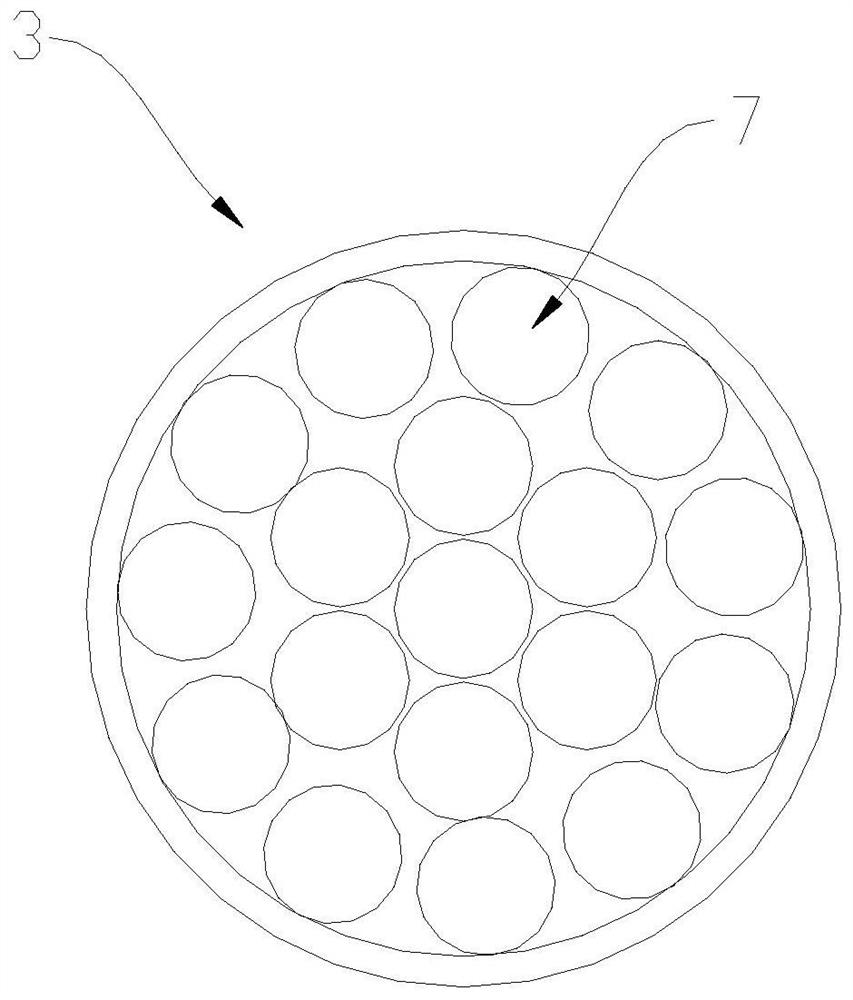

[0021] The charging connector 2 is provided with a charging socket 4 inside, and the inner wall of the charging socket 4 is nested with a cage-type ring belt sleeve 5 made of graphene metal material; the charging line 3 is made of graphene metal material. wire 7, and is formed by twisting or braiding a number of Litz wires 7; wherein, the graphene metal material used in the cage ring belt casing 5 and the Litz wire 7 is a composite material of graphene and copper, and graphene is in The addition ratio of copper is less than 1%; its electrical conductivity, mechanical properties and thermal conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com