Positioning rotary clamp for precise grinding of quartz nozzle

A quartz nozzle, positioning and rotating technology, applied in the direction of grinding device, grinding machine tool, grinding machine tool parts, etc., can solve the problems of time-consuming operation, easy waste products, roughness, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

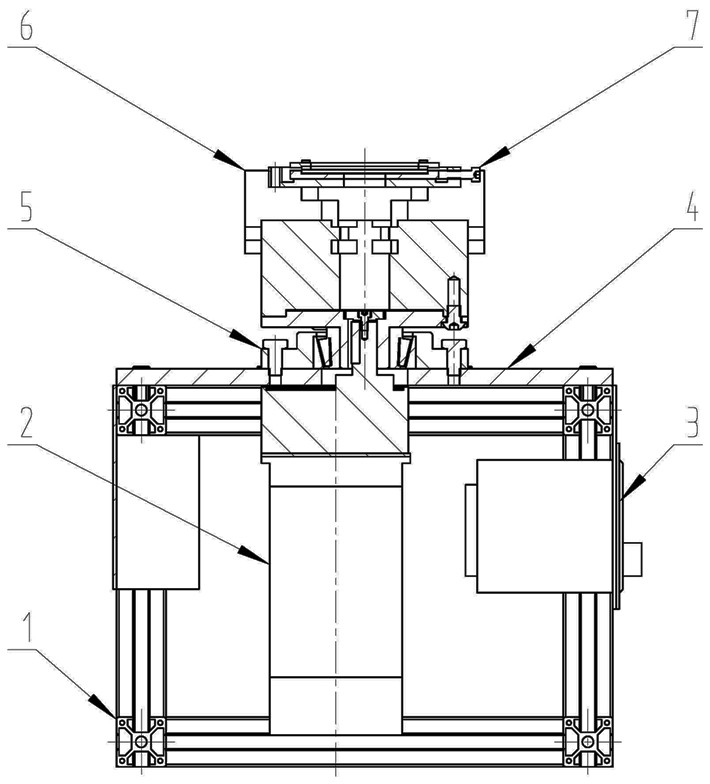

[0035] see figure 1 , a positioning and rotating fixture for precise grinding of quartz nozzles includes a frame 1, a worktable 4, a clamping and rotating mechanism 5 and an aligning mechanism 7. The workbench 4 is fixedly installed on the top of the frame 1 .

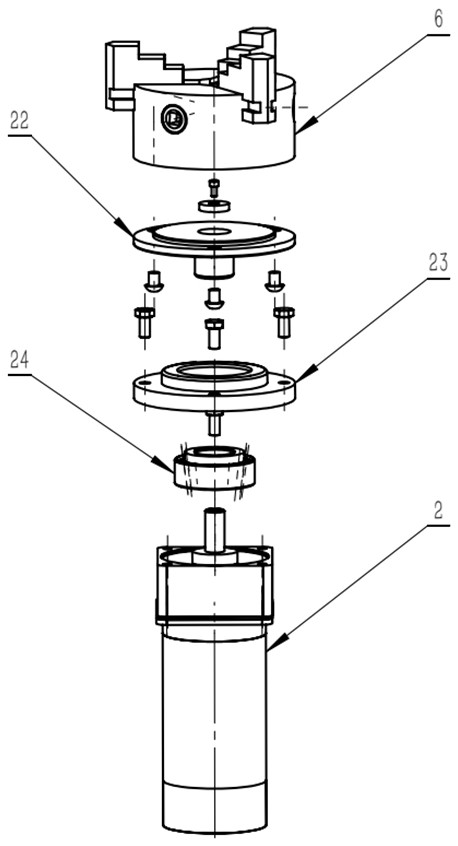

[0036] see figure 2 , The clamping and rotating mechanism 5 includes a motor 2 , a bearing 24 and a three-jaw chuck 6 . Motor 2 is a DC geared motor. The three-jaw chuck 6 is fixed on the connecting plate 22, and the connecting plate 22 is fixedly connected with the bearing gland 23. One side of the bearing gland 23 is provided with a central shaft in the axial direction, and the bearing gland 23 is fixed by the cooperation of the central shaft and the bearing 24. Installed on the output shaft of the motor 2; the bearing 24 is a single row tapered roller bearing. The motor 2 is fixedly installed on the bottom of the work surface 4, and the three-jaw chuck 6 is located on the work surface 4.

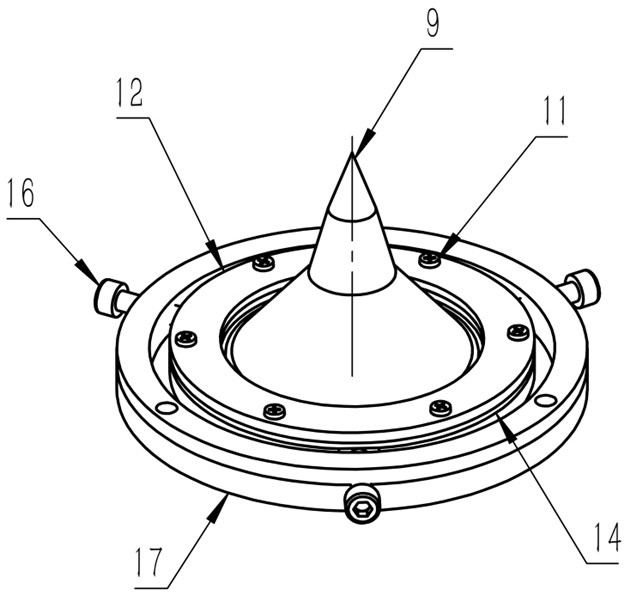

[0037] see image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com