Super-tonnage three-bridge rigid mining dump truck

A mining dump truck and super-large tonnage technology, which is applied to the arrangement of loading and unloading vehicles, vehicles used for freight transportation, motor vehicles, etc., can solve the problems of long transportation distance, large impact of road surface feedback on the frame, left and right deflection of cargo boxes, etc. , to achieve the effect of increasing fatigue life, reducing failure rate and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. However, it should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0035] Unless otherwise defined, all technical terms and scientific terms used herein have the same meaning as commonly understood by those skilled in the technical field of the present invention, and the terms used in the description of the present invention herein are only to describe specific implementations The purpose of the example is not intended to limit the present invention.

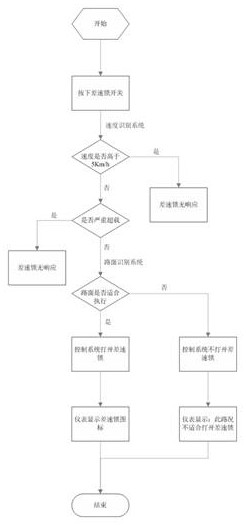

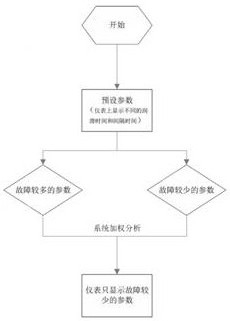

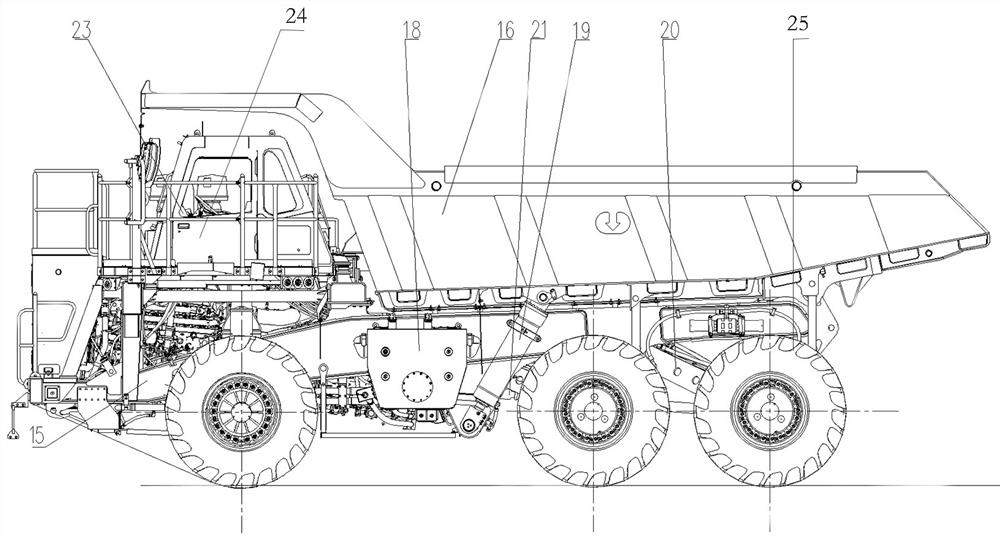

[0036] Such as Figure 1-8 As shown, a kind of ultra-large tonnage three-axle rigid mining dump truck includes wheels 25 and a cab 24, and also includes a rigid vehicle frame 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com