Cryopreservation tube suction control system

A technology of control system and cryopreservation tubes, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of cryopreservation tubes falling, freezing tubes not falling, and cryopreservation tubes easy to drop, etc., so as to improve efficiency , reduce the probability of damage, improve the effect of protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

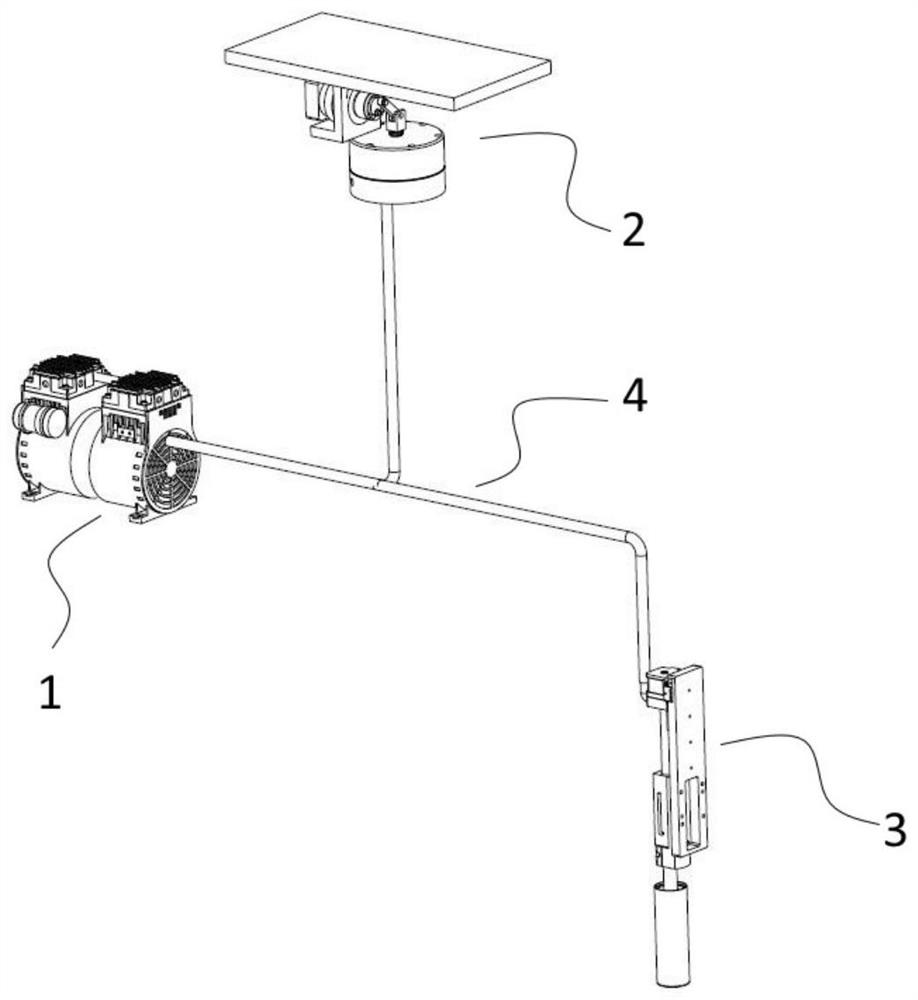

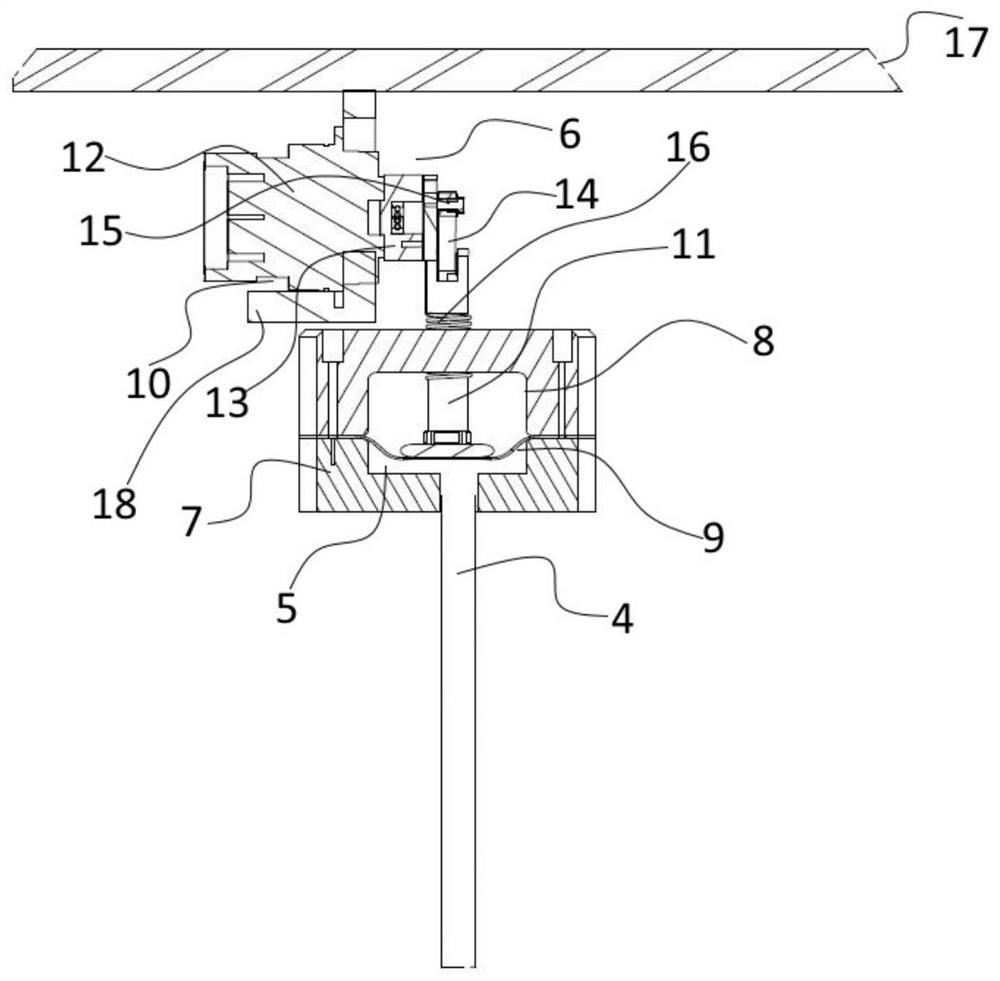

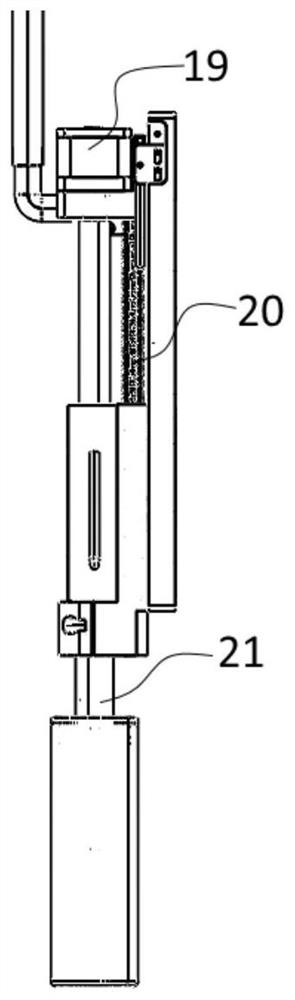

[0046] This embodiment provides a suction control system for cryopreservation tube 37, including a vacuum pump 1, a suction control device 2, and a cryopreservation tube suction device 3; a pipeline is passed between the vacuum pump 1, the suction control device 2, and the cryopreservation tube suction device 3 4 interconnected;

[0047] The suction control device 2 can control the suction or release of the cryopreservation tube 37;

[0048] The suction control device 2 includes a control cavity 5 and a control drive component 6. The control cavity 5 communicates with the cryopreservation tube suction device 3 through a pipeline 4, and the control drive component 6 drives the control cavity 5 to suck or release the cryopreservation tube suction device 3. force.

[0049] In the prior art, the cryopreservation tube 37 is often stuck in the nozzle of the suction pipe mechanism due to the excessive suction force of the vacuum pump 1, or falls due to the interruption of the suctio...

Embodiment 2

[0083] This embodiment provides a cryopreservation tube suction control system, including a vacuum pump 1, a suction control device 2, and a cryopreservation tube suction device 3; the structure of the vacuum pump 1 and the cryopreservation tube suction device 3 is the same as in Embodiment 1, The implementation mode of suction control device 2 is different from that of embodiment 1, the differences are:

[0084] The suction control device 2 is not limited to changing the vacuum state in the entire system through the suction and release movement of the control film 8. When the external suction force of the entire cryotube suction control system increases, the suction mechanism 21 has a greater impact on the cryotube 37. As the suction increases, the connection between the suction nozzle 26 and the cryopreservation tube 37 becomes tighter; when the external suction of the entire cryopreservation tube suction control system decreases, the cryopreservation tube 37 falls from the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com