Fly ash and red mud geopolymer material and preparation method thereof

A geopolymer and fly ash technology, applied in cement production, etc., can solve the problems of inability to popularize production and high cost of technology input, and achieve the effect of low cost and no fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

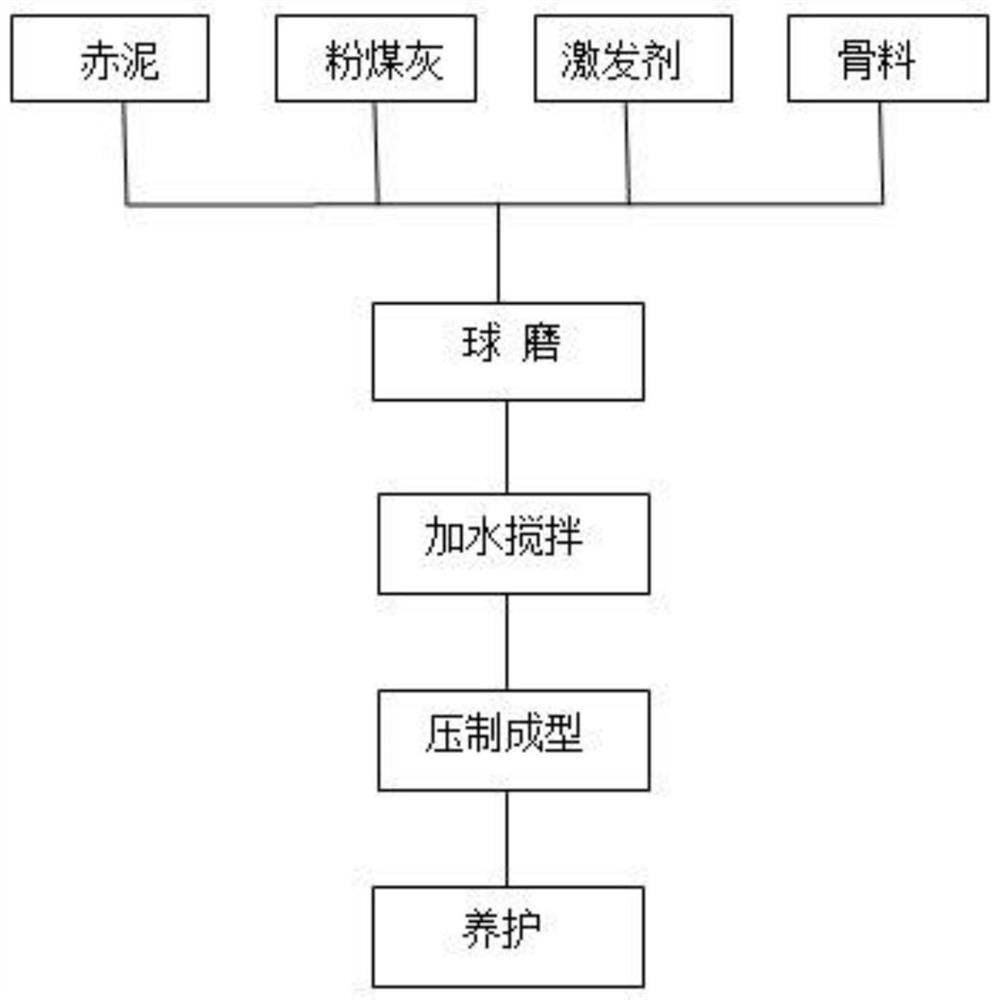

[0019] The preparation method of fly ash and red mud geopolymer material comprises the following steps:

[0020] (1) Mix the red mud, fly ash, lime and additives in the cementitious material according to the mass ratio of (10-60): (30-60): (5-30): (0.5-5) and then ball mill , to obtain powder after ball milling; the powder after ball milling all passed through a 60-mesh sieve and the remaining amount when passing through a 100-mesh sieve was less than or equal to 10%.

[0021] (2) The ball-milled powder and aggregate are mixed according to the mass ratio of 1: (0.2-1), then mixed with water, then pressurized, steamed and cured to obtain fly ash and red mud geopolymer materials, powder The coal ash and red mud geopolymer materials have a flexural strength of 3MPa-6MPa and a compressive strength of 25MPa-30MPa.

Embodiment 1

[0023] Mix 235g of red mud, 470g of fly ash, 188g of slaked lime, and 47g of desulfurized gypsum, and then add them to a ball mill for ball milling to obtain a ball-milled powder; when the ball-milled powder passes through a 100-mesh sieve, the remaining amount is less than or equal to 10% .

[0024] Mix the ball-milled powder with 940g of river sand and 225g of water evenly, and then pressurize the mixed material with a pressure of 15MPa to form it. After forming, put it into the curing box and steam it at 80°C for one day. After curing, put it at room temperature Under curing for 28 days, fly ash and red mud geopolymer materials were obtained. After testing, the 7-day flexural strength of the fly ash and red mud geopolymer material is 3.75MPa, the compressive strength is 18.5MPa, the 28-day flexural strength is 4.5MPa, and the compressive strength is 28.9MPa.

Embodiment 2

[0026] Mix 260g of red mud, 520g of fly ash, 208g of slaked lime, and 52g of desulfurized gypsum, and then add them to a ball mill for ball milling to obtain a ball-milled powder; when the ball-milled powder passes through a 100-mesh sieve, the remaining amount is less than or equal to 10% .

[0027] Mix the ball-milled powder with 559g of river sand and 282g of water evenly, then pressurize the mixed material with a pressure of 10MPa, and put it into a curing box for steam curing at 80°C for one day. After curing, put it at room temperature Under curing for 28 days, fly ash and red mud geopolymer materials were obtained. After testing, the 7-day flexural strength of the fly ash and red mud geopolymer material is 3.45MPa, the compressive strength is 17.6MPa, the 28-day flexural strength is 4.25MPa, and the compressive strength is 27.8MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com